From time to time, we all need a little bit of help. As a business owner, though, you may tend to pride yourself on your independence, and have a strong desire to keep all of your processes in-house. But what if soliciting design, assembly, testing, and fulfillment services could actually help you to grow your company an enable to you bring in more cash? That would probably grab your interest, and it has, indeed, peaked the curiosity of other small to midsize electronics businesses. A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 6 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

7 Reasons Contract Manufacturers Help You Stand Out

Topics: assembly manufacturing, electronics contract manufacturing, assembly manufacturing firm

How Contract Manufacturers Help You Stand Out

From time to time, we all need a little bit of help. As a business owner, though, you may tend to pride yourself on your independence, and have a strong desire to keep all of your processes in-house. But what if soliciting design, assembly, testing, and fulfillment services could actually help you to grow your company an enable to you bring in more cash? That would probably grab your interest, and it has, indeed, peaked the curiosity of other small to midsize electronics businesses. A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 6 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

1. Knowledge & Experience

Topics: assembly manufacturing, electronics contract manufacturing, assembly manufacturing firm

Assembly Manufacturing: Circuit Cards Ticket to Precision

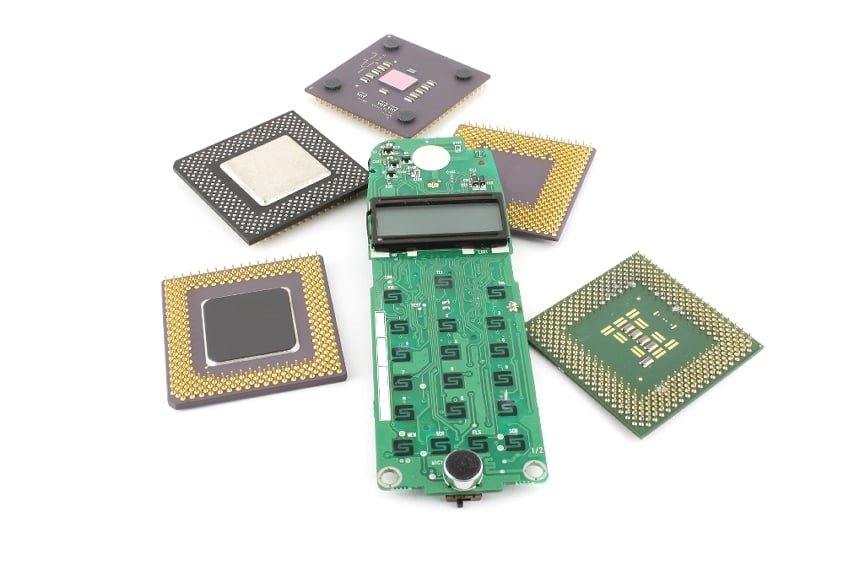

Maybe it goes without saying, but in the world of electronic manufacturing solutions, precision is everything. When you're dealing with circuit cards with layers of micro-printed circuitry, incorporating dozens of smaller sub-components, tiny mistakes can end up having large ramifications for your business.

Topics: assembly manufacturing, assembly process, assembly manufacturing services, assembly manufacturing firm, PCB manufacturing