Due to the fast-paced nature of this world, it's no surprise that the electronics industry is as competitive as it is. Electronics companies are constantly pushed to reach beyond their limitations to create devices that are more compact and more advanced, while still keeping prices low. The expenses involved with creating new products, however, can make it very difficult to keep customer costs down or to make much of a profit. It is for these reasons that a growing number of companies are seeking out help from outsource vendors. But is this the best solution for you? If you're not certain, here are four key reasons that you should seriously consider working with a contract electronics manufacturer.

1. Gain New Insights

Although there is no doubt in your mind that your team is highly knowledgable and good at what they do, you should never convince yourself that you or your staff have nothing left to learn.Technology is constantly evolving, and new ideas and methods are continuously being developed in order to streamline the process of designing and building better electronics. A contract electronics manufacturer can bring these new concepts to the table, opening your eyes to a world of new possibilities. Your contract partner may be able to point out ways to adjust your product designs in such a way that production costs will be reduced, or your device will run smoother, and with a reduced likelihood for malfunctions or other issues. Additionally, an electronic contract manufacturer can help you to work out problems and kinks that your team has been struggling to resolve, so that you can keep your business moving forward and making money.

2. Take Advantage of the Most Advanced Technology

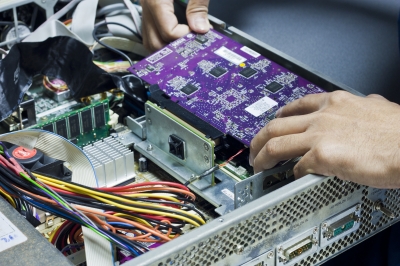

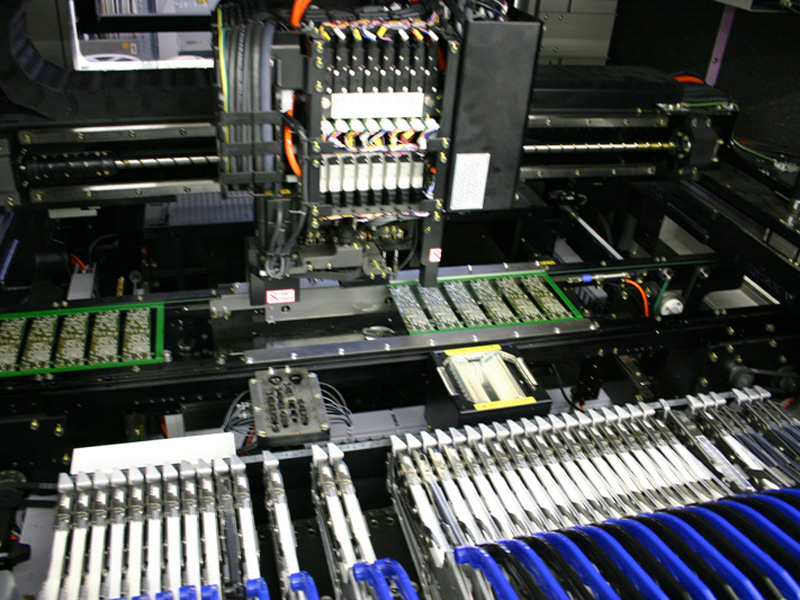

For the largest enterprises, it may not be as difficult to spend the money on advanced technological upgrades every year or two. For smaller and medium sized business ventures, on the other hand, this may not be possible. When your company's cash flow is tied up or somewhat restricted, it can be impossible for you to make the investment in the latest and greatest manufacturing machinery which, in turn, makes it very hard for you to keep up with the competition. A contract electronics manufacturer can "level the playing field" by offering your business access to more advanced technologies throughout the production of your devices. Robotic arms can be utilized to manipulate even the smallest parts with care and precision, so that human-error can be removed from the equation. Fast, accurate machinery will speed up the product assembly process without ever detracting from the operability of your electronics, so that you can stop wasting money on time and faulty equipment.

3. Improve Customer Satisfaction

By working with a contract electronics manufacturer, you can improve the quality of your products and ensure that your customers will be happier with their devices. This is not only due to the fact that the machinery and equipment used to manufacture these devices is so precise and advanced, but because the best parts are used, and all products are tested for quality. A good, American-based contract partner will never utilize bootlegged parts during the manufacture process, and will have a solid system in place for verifying product functionality.

4. Broaden Your Horizons

From start to finish, a contract electronics manufacturer can speed up your processes while improving the design and production of your devices. Because of this, your business will become more efficient and organized, freeing up the time for you and your team to "dream big" and develop new, more exciting and technologically advanced products to share with your customers. At long last, you will have the time, technology, and financial resources available to become the industry leader that you always wanted to be.

Stop holding yourself back, and start finding out how working with a contract electronics manufacturer can transform your business into something bigger and better than ever before.

4 Reasons To Use A Contract Electronics Manufacturer

Topics: contract electronics manufacturer, electronic contract manufacturer, manufacturing machinery

5 Ways You Could Benefit From Assembly Manufacturing

In today's economy, many businesses are the outsourcing assembly manufacturing to overseas companies as a means of saving money. But although this is initially less expensive, in the long run, it could cost you big time. Bootlegged products, shoddy craftsmanship, and failure to comply with safety regulations could lead to significant losses in revenue, a damaged reputation, and even fines or lawsuits. Because of this, it is wise to bring assembly manufacturing back home, and work with an American based electronic contract manufacturer that specializes in the design and production of complex electronics. Here are just five of the many reasons why doing this could work to your advantage.

1. Fast, Attractive Prototypes

When you are taking on a new client who is interested in the electronic products that you have to offer, they will want to see an example of your work before signing a contract and giving you their business. In some cases, your clients may need a device that is customized to their specific needs, which means that you will need to have the ability to quickly design and produce a workable prototype. A professional contract manufacturer will be able to help you to come up with a flawless design plan, and through a high-tech assembly manufacturing process, you can turn out the prototype fast. This will give your new client the assurance that you can work at high seed, while still creating a quality products and meeting their demands.

2. Catch Errors Quickly

An offshore company may utilize non-skilled labor as a cheap means of handling the assembly manufacturing process. Unfortunately, this means that hundreds of your products could be put together incorrectly, or with faulty parts before anyone notices. In fact, your device could actually end up on store shelves or shipped to your customers before the mistakes are detected. An experienced American contract manufacturer will be staffed with experts who will be able to prevent problems like these from happening. Skilled workers with a trained eye will be able to spot issues quickly and fix them to minimize losses and uphold your reputation.

3. Utilize the Best Technology

When you have an assembly manufacturing partner, there's absolutely no need for your business to continuously try to "keep up with the Joneses" in terms of investing in better, more advanced equipment. Your contract manufacturer will keep their facility current with the latest and greatest machinery for producing electronics, so that you can take advantage of advanced machinery and precision robotics without spending a dime of your own.

4. Testing and Quality Control

With the right contract manufacturer, you can count on the fact that your products will be manufactured correctly, from start to finish. Your partner will even test your completed devices in-house to ensure functionality and operability before sending them to your clients. This will ultimately prevent the losses and embarrassment involved with having to recall a product, or re-do an entire order as a result of overlooked flaws and mistakes.

5. Sell the Best Products

At the end of the day, your primary objective is to give your customers and clients the best possible electronics possible. If you are trying to handle large orders in-house, you may struggle to keep up with demand, which will lower the quality of your devices. On the other hand, we have already seen how outsourcing the assembly manufacturing process to an offshore location can be damaging to both your company and the end users.

Topics: assembly manufacturing, electronic contract manufacturer

Don't Throw It Away, Use Electronics Repair Services Instead

Although it's unfortunate, we live in a very wasteful society. If something stops working, very few people take the time to fix it - the item is simply discarded and replaced. In the world of electronics manufacturing, however, this isn't always a possibility. After spending a great deal of time in the engineering design services phase and spending the money to manufacture a prototype or product, simply "junking" a malfunctioning device could result in the loss of thousands or even tens of thousands of dollars - and that doesn't include the amount of money lost on the potential sales of the product, had it been successful.

Topics: electronics repair services, electronics contractor, repair electronics services

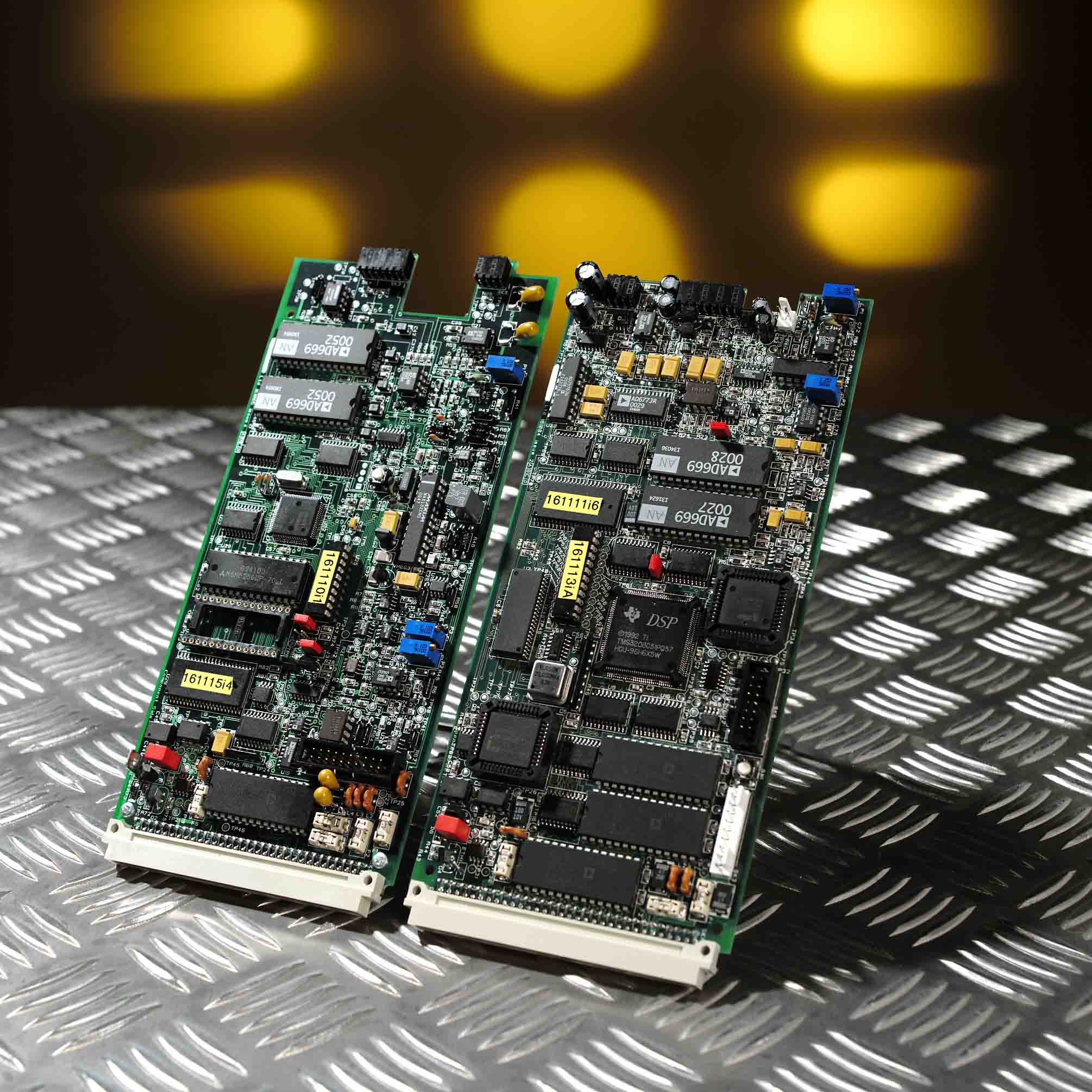

Bigger doesn't always mean better - especially in the world of technology. As the digital revolution continues to expand our capabilities, electronic devices continue to shrink into smaller, more compact units. Because of this, electronics companies must take advantage of advancements in manufacturing technologies like PCB assembling.

Topics: pcb assembly, PCB Assembling, pc board assembly

A Printed Circuit Board, abbreviated as PCB is a foundation used in the design of electrical gadgets. It plays to important roles:

Topics: pcb assembly, electronic assembly, electronic PCB assembly

EMS (Electronic Manufacturing Services) generally refers to companies that design, test, manufacture and sell electronic gadgets while offering a return/repair services or assembly of original electronic equipment. While this might sound as an easy task, it is a hard to achieve investment that once up and running will deliver quality assurance to a wide variety of customers and a go.

Topics: electronics manufacturing, ems electronics, electronic design

SMT Production: Know The Basics Before You Start

There are different approaches to mounting components onto a printed circuit board with each method having its own strengths and weaknesses. This brings up the need of understanding what a given circuit is expected to do hence going for an approach that will bring the best in terms or performance and durability out your circuit.

Topics: surface mount technology, SMT Assembly, smt manufacturing