These days, electronics are everything. We are all wired in, whether for communication, work, or recreation. At the very heart of all of our electronics devices are the PC boards that allow them to operate and function as intended. As the years go by, the need for these boards to become more dense, more complex, and yet more compact has become even greater. As a result, electronics companies must understand and anticipate consumer needs so as to develop boards and products that will sell and satisfy. Despite the fact that most consumers will never give a second though to the boards running their devices, this is arguably the most important part of product development. Do you know what goes into the design and assembly of your PC boards? Read on to learn more.

Topics: pcb assembly, Contract Electronic Assembly, PCB Assembling

5 Saving Money Without Sacrificing The Quality Of PCB Assemblage

It really doesn't matter what type of business you're in - money is a common stressor for all of us. Despite the fact that the economy is improving, the majority of American industries are constantly looking for ways to scale back their costs and improve profit margins without sacrificing the quality or integrity of their work. Still, this is often much easier said than done. Finding areas where you can safely and effectively reduce spending while still keeping your customers happy with excellent products and services isn't as simple as it may seem, and it can be especially problematic in the electronics sector.

Topics: assembly manufacturing, American PC Board Assembly, PCB Assembling

Although you may be giving some thought to contracting with a third party to assist you with the manufacture of your PCBs, you may also be feeling about unsure about it. Entrusting an outsource vendor to construct your products to the your specifications and the quality you desire can be difficult. But when you find the right partner, using an assembly PCB professional can really do wonders for your business. Still not convinced? These five perks of using an outsource company to handle your company's assembly PCB needs should encourage you to contract with a reliable partner.

Topics: assembly pcb, PCB Assembling, PCB Assembly Partner

Surface Mounted Technology, What Is It All About?

What is Surface Mounted Technology (SMT)?

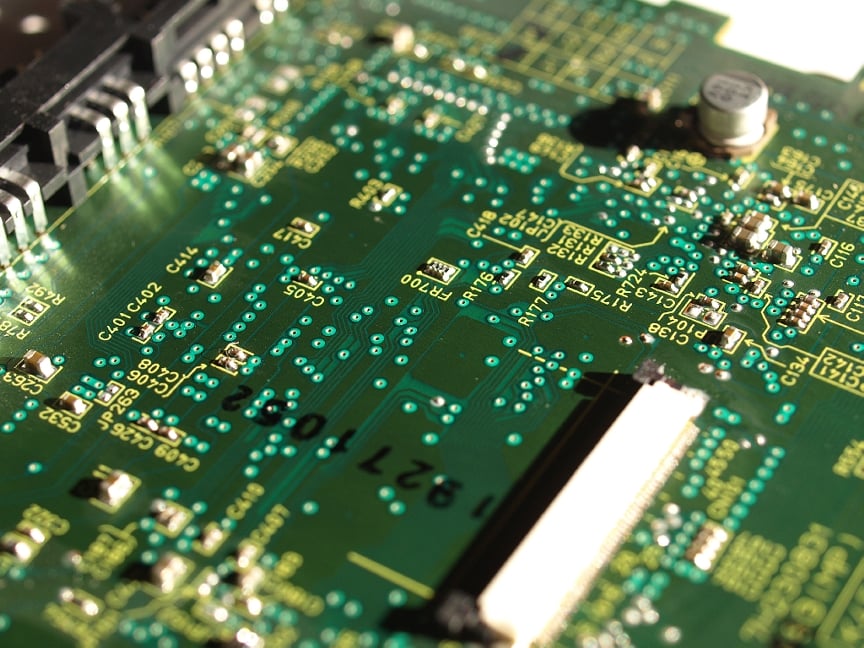

In SMT, components are placed directly onto the surface of a PCB in order to create what is known as a surface mount devise (SMD). Due to its efficiency and effectiveness, SMT has widely replaced through-hole technology methods for constructing PCBs, however, both methods can be utilized on the same PCB. This is because there are some components that are simply not suited to surface mounting. These components might include large transformers and heat-sinked power semiconductors. Generally speaking, SMT components are smaller in size than through-hole units as they have smaller leads or do not have any leads at all.

What are the Advantages of Surface Mounted Technology?

The primary advantage to SMT, of course, is size. Because today's electronics are expected to be more compact, there is an increase in demand for smaller units. SMT makes this possible. But despite the fact that these units are not as bulky as older devices, there is actually a much higher component density, as well as more connections per each component. This means that electronics can be more efficient and advanced than ever before, while still being as compact as possible. Fewer holes need to be drilled into the boards which leads to faster and more automated assembly processes, and the fact that components are able to be situated on either side of the circuit board simplifies things further. On top of this, there are many SMT parts and components that actually cost less than their through-hole counterparts. All of this results in a lower initial cost, less time required for setting up and production, reduced manufacture cost, and a more efficient use of time.

What are the Disadvantages of Surface Mounted Technology?

Unfortunately, there are no perfect or fool-proof manufacture processes, and SMT does have its drawbacks as well. As an example, SMT is not suited for any large, high-power/high-voltage parts. Because of this, SMT and through-hole construction may need to be combined for better results. Additionally, the small size of SMDs can create issues, in that the solder joint dimensions continue to grow smaller as advances are made toward ultra-fine pitch technology. Ultimately, this means that less solder is able to be used for each joint which can result in voiding, and integrity issues. The solder connections of SMDs are also capable of being damaged by plotting compounds as they go through thermal cycling. Lastly, SMT should not be used as the sole attachment method for any components that may be subject to ongoing mechanical stress, for instance, connectors that are utilized to interface with external devices which are often attached or detached.

When Should Surface Mounted Technology be Used?

Because of its many benefits, the majority of products manufactured at this time utilize surface mounted technology. Despite this, we have seen that SMT is not suitable in all cases. As a rule, SMT should be considered if:

- Your products must be very small/compact

- Your products must be able to accommodate large volumes of memory

- Your final product needs to be sleek and light despite component density

- Your product will need to be able to function at high speed/frequencies

- You need to produce large quantities with automated technology

- Your product should only transmit very little noise (if any at all)

- Your product must be able to accommodate a great deal of large, high lead-count complex ICs

Topics: contract manufacturing company, PCB Assembling, surface mounted technology

Bigger doesn't always mean better - especially in the world of technology. As the digital revolution continues to expand our capabilities, electronic devices continue to shrink into smaller, more compact units. Because of this, electronics companies must take advantage of advancements in manufacturing technologies like PCB assembling.

Topics: pcb assembly, PCB Assembling, pc board assembly

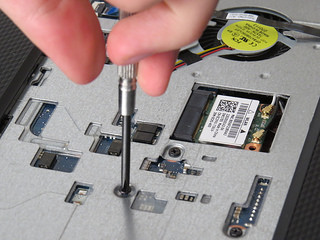

Pick A Process And Create It With PCB Prototype Assembly

Whether you are a buyer of manufactured electronic components or the engineer assembling the PCB, you should know that there are several different processes which can be utilized for any of your projects. This is especially true when it comes to PCB prototype assembly, because finding the right process that will save time, money, and create a high quality product is of utmost importance.

Topics: electronic design and manufacture, PCB Assembling, pcb prototype assembly