Things To Look For In Electronics Manufacturing Services

Topics: electronics repair services, assembly process, electronic contract manufacturer

Realizing The Value Of Working With A Contract Manufacturer

As an electronics business, your goal is to provide your customers with superior devices, powered by efficient and highly-functional PC boards. You want to keep buyers happy with boards that will continue to support your products for many years. But despite your best efforts, there's always the chance that something will go wrong with one of your devices. How do you handle it when there's trouble with one of your units? Do you simply cut your losses and ship a warranty replacement unit?

For many small to mid-sized companies, this may seem like the simplest solution, but is it really worth it? In many cases, the problems associated with a faulty device can be traced right back to the PC board. Through troubleshooting, you might find that the issue really boils down to one or two components that may need to be replaced, or another quick fix. Ultimately, taking the time to make these adjustments can save you a significant amount of money.

Topics: electronics repair services, assembly process, electronic contract manufacturer

In any industry, it's extremely important that you're able to keep up with (if not surpass) the competition by offering the very best products and services. This is especially true in the electronic sector. With every passing moment, further advancements are being made in our technological capabilities and processes, which results in a consumer demand for increasingly complex yet affordable and user-friendly products. Of course, behind every great electronic device is an advanced, well put-together PC board.

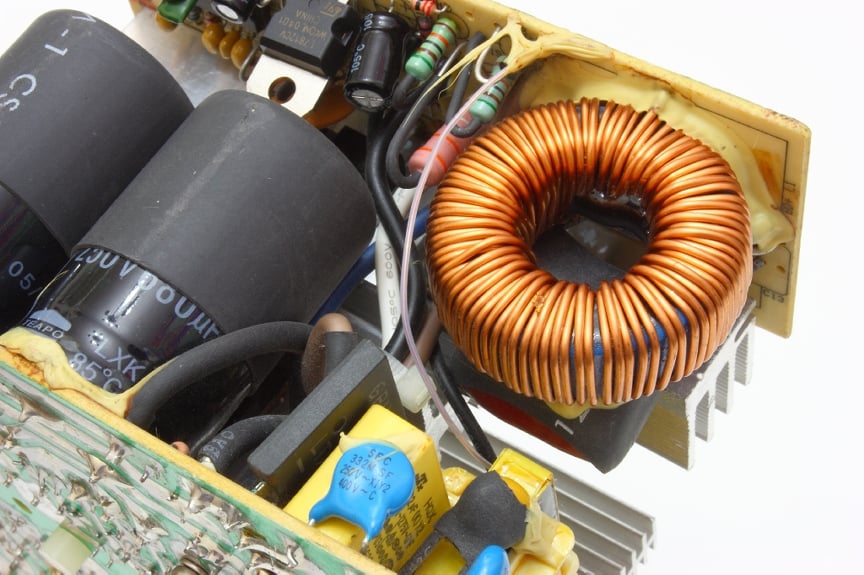

It's true! Although most users will never even take a glimpse at a PCB (let alone begin to understand how it works), these units are the backbone of our technology. As such, it's absolutely crucial that a lot of care goes into the manufacture and assembly process. But what is it that sets a superior PC board apart from a mediocre or low-quality board? Unless you know, you could end up partnering with a less-than-qualified contract manufacturing company. To eliminate any future stresses or headaches on your end, let's take a look at what actually goes into the assembly of the best PCBs.

Topics: assembly process, assembly pcb, pcb design

Assembly Manufacturing: Circuit Cards Ticket to Precision

Maybe it goes without saying, but in the world of electronic manufacturing solutions, precision is everything. When you're dealing with circuit cards with layers of micro-printed circuitry, incorporating dozens of smaller sub-components, tiny mistakes can end up having large ramifications for your business.

Topics: assembly manufacturing, assembly process, assembly manufacturing services, assembly manufacturing firm, PCB manufacturing