As the rest of the world continues to rely on electronics and technology, in turn the technology becomes even better and a convenience to society. So, how is the assembly of such electronics and components affected from this rapid change and upgrading? Business is certainly booming, and there are all sorts of updates that have been made in order to offer the best quality and prices to clients who regularly use assembly manufacturing for their own projects.

Assembly Manufacturing In Today’s Electronic World

Topics: electronics manufacturing, assembly manufacturing, assembly manufacturing companies, PCB manufacturing, precision manufacturing

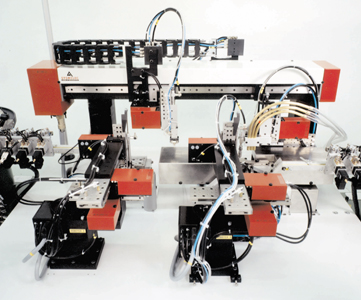

Precise Product Assembly Engineered To Enhance Quality

For all of the assembling and designing that goes into a product, shouldn't the precision of the assembly and how it enhances the overall quality of the final product be a high priority for you as well? If you haven't thought about the process which your assembly company utilizes to create your projects and just how much precision is applied, perhaps it's time to take a step back and realize just how much it really does matter and reassess your next project.

Topics: assembly manufacturing, product assembly, precision manufacturing