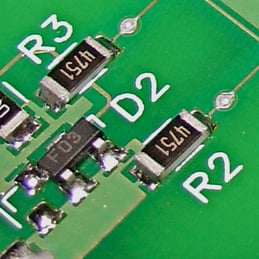

Circuit boards manufactured with Surface Mounting Technologies have revolutionized electronics manufacturing, thanks to their ease of construction and the much higher component density they make possible. SMT construction allows for devices which are smaller, more feature-packed, and (very often) cheaper to produce.

Circuit boards manufactured with Surface Mounting Technologies have revolutionized electronics manufacturing, thanks to their ease of construction and the much higher component density they make possible. SMT construction allows for devices which are smaller, more feature-packed, and (very often) cheaper to produce.

SMT manufacturing does introduce new challenges, especially when it comes to repairs and other rework. Because SMT boards can utilize components that are only a fraction of a square millimeter in area, traditional soldering techniques often cannot be used to rework them. A single dollop of solder could bury entire components!

When your SMT-created products need rework, there are two basic options if soldering can't fix it. Both have their advantages and disadvantages, and it's good to know which technique(s) your own manufacturing shop is using.

New SMT Manufacturing Techniques Demand New Rework Techniques

The key to reworking with SMT products is the use of non-contact methods, to avoid causing additional damage to the board. Usually, these are combined with either computer controls or precise microscopes to guarantee accuracy.

I. Infrared

Infrared rework systems are generally the easier to install and use, as they are based around a "gun" firing long- or short-pulse blasts of IR energy to heat up the soldering around components. They can be nearly as precise as a laser beam, IR is also very quick to heat up the solder, so infrared rework systems allow for faster repairs.

However, IR systems also suffer from some drawbacks. Because the beam is so precise, this can lead to uneven heating of a surface. Changes in albedo (light vs dark surfaces) between components can also cause uneven heating. Also, on denser boards, there's enough radiant heat that shielding may be needed to protect nearby components and their solder.

Infrared is generally the more cost-efficient option, when it's feasible.

II. Hot Gas

The other option in SMT manufacturing rework is the use of hot gasses, usually either standard air or nitrogen. With hot gas, the overall temperature can be precisely controlled. The gas also creates a much more even heat distribution, as well as generally simulating conditions within the reflow ovens which finish SMT circuit boards. In other words, they use the exact form of heating the solder and boards were built for.

More advanced hot gas rework systems can even include a cooling chamber, again, to recreate the original conditions under which the circuit board was created. This allows even reworked boards to adhere to very precise manufacturing standards.

There are no real downsides to hot gas in terms of effects on the board, but such systems are somewhat more expensive to operate. They require the use of compressed gas, which can cause safety concerns as well. Such techniques are also generally a bit slower than IR, although the time for rework will vary substantially based on the individual properties of the board being repaired.

Rework Options Add Value To SMT Manufacturing

Whether it's for correcting inevitable defects coming off the assembly line, or adding full product repairs to your list of post-sale services, SMT rework techniques can substantially increase the value and ROI for your manufacturing investment.

If you have questions about Surface Mounting Technologies or any other queries about modern electronics manufacturing, just contact ZenTech for the answers.