Electronics companies in the 90s and 2000s which chose to outsource their production work overseas often found themselves making compromises. The great distances and language barriers involved often introduced new issues that had to be worked around, often to the detriment of the product, the customers, or both.

Electronics companies in the 90s and 2000s which chose to outsource their production work overseas often found themselves making compromises. The great distances and language barriers involved often introduced new issues that had to be worked around, often to the detriment of the product, the customers, or both.

One of the most obvious of these -and the most costly- is what happened to post-sale support in the wake of the offshoring boom. A big change was made to how a lot of companies handled warranty claims: Rather than attempting to repair the item, they simply sent out a new one every time.

Granted, there are cases where this can be cost-effective, but when talking about products that can be hundreds of dollars on the shelf, it's incredibly wasteful to send out new ones when often a single low-cost component is to blame.

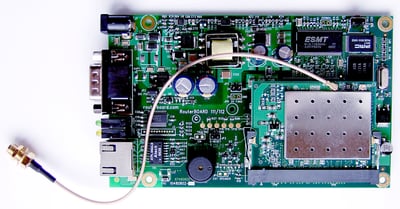

Partnering with an electronics manufacturer who provides their own PCB board repair and associated post-sale services can save you plenty in the long run, while improving customer experience along the way.

5 Ways In-House PCB Board Repair Services Pay Off

1 - Lower replacement costs

The obvious benefit, of course, is that actual repair services can save plenty of money on warranty support, by minimizing the amount of waste in replacement services. Full-product replacements should be considered a last resort. Actual component-level repairs are almost always a more cost-effective option,

2 - Less e-waste

When a company receives a defective product and sends out an entirely new one in return, what happens to the original product? Much of the time, it's simply thrown away.

E-waste is becoming a serious concern worldwide for a wide variety of reasons, and eco-friendly buyers are increasingly asking what's happening to a company's waste. If you can say you're implementing policies to eliminate e-waste, it's going to pay off in PR.

3 - Customers keep their customizations

One of the biggest problems with "full product replacement" policies, from the consumer\buyer point of view, is they never get their own device back. If it's able to be customized or holds a lot of data, this can become a serious issue with customers.

Being able to guaranteed that, in most\all cases, the buyer gets back their own device with their settings\data untouched means a lot more security on the part of your customers.

4 - Better support interactions

According to recent numbers, 78% of consumers have walked away from companies due to poor customer service experiences. 59% will try a different brand specifically in hopes of finding a better customer experience.

Consumers and buyers are rapidly losing patience with poor CS, and they virtually always have alternatives. Having customer support that's directly tied to your manufacturer means customers get quality support, and that turns straight into better customer-retention figures.

5 - Optimized problem reporting and correction

Finally, consider the payoff to your ongoing process of product refinement. In-house CS means that your manufacturer has ongoing feedback about the quality of the product, and unknown issues can quickly become known -and then fixed- because of close communication between the tech workers and the engineers.

That interaction allows for faster refinement cycles, and improved recognition of design flaws that slipped through testing.

Want to learn more? Contact Zentech today for a full consultation on our full in-house PCB repair and support services.