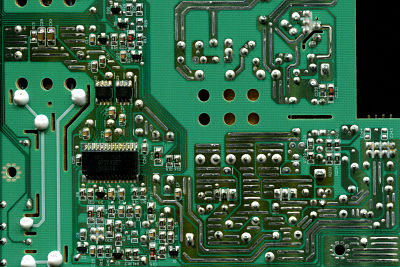

The design of printed circuit boards (PCBs) is one of the most important steps in manufacturing a quality electronic device. The functionality and efficiency of your electronics depend on the design and layout out of the board (or "brain") of the gadget, meaning that nothing can be left to chance. Through careful attention to detail, the board can be designed to meet all product specifications without wasting any space or utilizing excessive components. This enables the device to remain as compact yet information-rich as possible, meeting the demands of the consumer marketplace. But do you know what goes into superior electronics design services?

The design of printed circuit boards (PCBs) is one of the most important steps in manufacturing a quality electronic device. The functionality and efficiency of your electronics depend on the design and layout out of the board (or "brain") of the gadget, meaning that nothing can be left to chance. Through careful attention to detail, the board can be designed to meet all product specifications without wasting any space or utilizing excessive components. This enables the device to remain as compact yet information-rich as possible, meeting the demands of the consumer marketplace. But do you know what goes into superior electronics design services?

Many small to midsize electronics companies have difficulty in recognizing where they are going wrong. While businesses like your own may have carved a niche for themselves within the industry, you may be struggling to keep up with your larger competitors and grow. In order to improve your products and become an even better operation, you need to begin at the beginning: examining your PCB design and learning to understand how it impacts the completed products. To emphasize the importance of doing so, we've written this post to walk you through the basics of electronics design from concept to completion.

Understanding the Problem

Before you can assess the design to finish process, you need to first have an understanding of what the underlying problems are, and why it's so valuable to consistently assess processes and seek help, where needed. Although it's unfortunate, even skilled engineers have been known to be guilty of designing PCBs that meet the client or product specifications, but still present significant challenges during the actual board production. This doesn't necessarily reflect poorly on the engineer's abilities, but rather, indicates that the designer simply may not be familiar enough with the downstream manufacturing process and how their decisions during the design process can actually impact it. Boards may be designed in such a way that mounting becomes difficult, or where too many components are being utilized, creating issues with being able to keep the end product operating smoothly, while still remaining sleek and compact. It's extremely important, then, that those designing the board have an understanding, no only of what goes into planning the overall design of the board, but how the assembly and production process work as well.

The Concept to Completion Solution

Having a "big picture" understanding about how PC boards must be designed and produced is the only way to develop efficient, effective, and economical electronics. The following steps should be followed:

-

Concept - In this step, you and/or your client are determining what your goals are for the completed project, and how the board will need to function in order for your to achieve those goals. What capabilities will the board need to have? Must it be compact or irregularly shaped in order to work within the device? Are there any budgetary constraints? All questions must be clearly answered here.

-

Mindful Design & Layout - The design and layout phase of board development shouldn't begin until its concept and expectations have been drawn up. A skilled team of engineers must then work to meet each and every one of these expectations while also keeping the ease of manufacture and financial restrictions at the top of mind.

-

Thorough Testing - Prior to production, computerized testing should occur in order to pinpoint any design shortcomings or flaws.

-

Prototyping - It's always smart to take testing one step further with a prototype to ensure that the board functions correctly. Any fine-tuning should occur once the prototype has been examined and tested.

-

Manufacturing to Completion - It is only once it's been decided that the board is operational, the assembly manufacturing process can begin.

If your concept to completion processes are skipping any of these steps, it's time to re-assess and re-group. You may also want to consider seeking help from an electronics design service to streamline your board design.