Everyone loves a “win-win”

This is especially true when it comes to highly complex electronic assemblies with high- tech/high-reliability products such as Defense, Space, Medical, RF and Microwave applications. It makes sense, since many of these products preserve or protect lives and enable critical communications. The goals of customers in these industries is always the same: Control costs while keeping reliability high and, ultimately, making a reasonable profit. It’s not rocket science. (Well...okay, sometimes it is!) Based on your company’s experience, you may be surprised to hear that, for most EMS companies, our goals are exactly the same. After all, when we help you succeed, we succeed. Win-win. So why do these seemingly simple objectives seem so elusive at times?

Complexity that Complicates

Managing the complexities of the full spectrum of an electronic assembly’s supply chain is daunting. It spans from concept to schematic design, board layout, board fabrication, documentation, supplier qualification, materials acquisition (that can involve dozens of suppliers and distributors), parts kitting, SMT and thru-hole assembly then, at last, to shipping logistics…and this is the short list! Your completed circuit card or sub-system assemblies may also include plastic molding, metal fabrication, potting, conformal coating, mechanical assembly, FPGA programming, customized test, environmental test, lifecycle tests and perhaps many other steps along the way. Every step must be completed with pristine accuracy—on time, within budget, and result in impeccable reliability. This is an interconnected puzzle in which each step impacts the other, and it often requires a partner who can offer full integration that will help control quality and cost throughout. Here are a number of ways Zentech strives to meet our customer’s needs (beyond our core circuit card assembly services) by helping them keep their costs low and their reliability high:

Engineering and Design Services:

We have in-house engineers to help support your engineering team in regards to meeting performance goals as well as addressing Design for Manufacturing (DFM) concerns that will impact the form, function, cost and reliability of the final product. We also have top PCB design professionals to help navigate complex layout issues, or to take on the entire layout and documentation portion of our customers projects. These individuals are highly skilled to watch for DFM issues relative to board fabrication, assembly and beyond.

PCB Fabrication

We have worked with the best PCB Fabricators in the country for many years. In most cases, we have already developed a close working relationship with the fabricator of your choice. Additionally, we have qualified an elite network of PCB suppliers that have been evaluated according to our very stringent standards and criteria. Due to the higher volume of our total board usage, our purchasing power helps us negotiate competitive pricing and helps ensure excellent responsiveness on your behalf.

Material Acquisition

One of the most complicated and tangled “webs” along the continuum of the supply chain is materials acquisition. Proprietary parts, distribution channels, obsolete parts, counterfeit parts, packaging, and attrition. The list goes on and on. We have a dedicated and sophisticated team covering all these aspects and more. Furthermore, we have a strong buying position resulting from the collective quantities we procure for our customers. Furthermore, we have highly efficient proprietary systems in place to buy on-demand and kit that keep waste and attrition to a minimum. We can provide in-depth screening to weed out counterfeit parts. We eliminate the need for carrying costly inventory and offer a streamlined, efficient method to manage materials that greatly reduces the inherent risks and exposure that costly parts acquisition can cause for our customers--while keeping costs extremely lean.

Best Equipment and Tool Sets

Due to our experience, success, and available capital resources, we are able to expertly evaluate and purchase the very best equipment and tool sets that turn-key electronics manufacturing demands. As devices shrink and fine-pitch parts continue to push the limits of technology, we continue to acquire equipment like in-line 3-D X-ray inspection and Solder Paste Inspection (SPI) to ensure extremely accurate placement of components and sound solder joints. Each time technology pushes forward, we respond by acquiring the very best equipment and tools to meet these new challenges. This saves customers millions of dollars in cash-outlay associated with in-house assembly—not to mention the expense of the high cost of skilled labor.

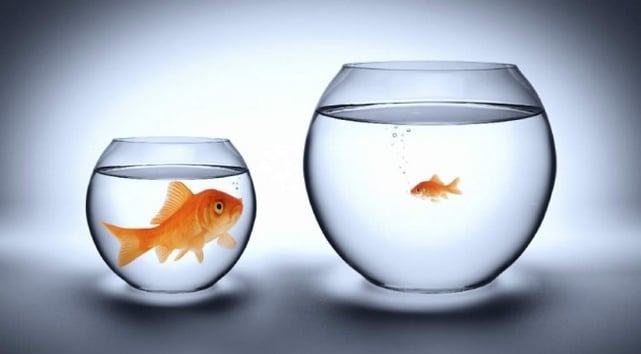

One Size Never Fits All

One Size Never Fits All

When contracting with a CM partner, the size of the company matters. If you contract with a large multi-national company—you will reap all the benefits mentioned above. However, agility, responsiveness and lead-time often suffers. When you need a quick-turn for a prototype, a large CM may be hard-pressed to meet your needs, or they may need to send your prototype to an alternate location somewhere across the country. The lumbering size of these operations, can’t help but slow response time and you may end of being a tiny “fish” in a very big ocean of customers. On the other hand, if you go with a company that is small, agile and very responsive—they may not be able to keep up with capitalizing appropriately to meet the challenges of evolving technologies, or have critical strong buying power, or have the highly skilled team to negotiate the best prices and response time for material acquisition. At Zentech we try to address the needs of both large and small customer’s alike under the roofs of two centralized facilities. We can address the mid-large run requirements at Zentech’s main purpose-built facility, while our fully-owned nearby 2nd facility, Colonial Assembly and Design can tackle the small to mid-sized build requirements. In other words, we are small enough to be extremely responsive, but large enough to enjoy the benefits realized by the best equipment, available capacity and strong buying power—not to mention a staff that is highly skilled, trained and certified.

…And all the other stuff!

Time does not permit us to elaborate on our other abilities such as mechanical assembly, potting, conformal coating, highly sophisticated test protocols, box builds, molding, shipping and so many other abilities and services—most of which reside within our facilities. Just know, Zentech keeps your goals in sight every day. We have a model that keeps the very large, and very granular objectives in mind and embody all that it means to be a real partner. We enable our customers to lower their total cost of ownership (TCO), while never ever losing sight of reliability—because we know…everybody loves a win-win!

Contact us today, to find out more about how we can create a custom-tailored solution to for you and your company!