EMS Electronics design becomes more and more difficult to do well, as we continue to push both density and speeds higher when it comes to circuit design. High-RF designs require highly precise and controlled manufacturing to produce boards capable of standing up to lengthy use, and with sufficiently low failure rates.

EMS Electronics design becomes more and more difficult to do well, as we continue to push both density and speeds higher when it comes to circuit design. High-RF designs require highly precise and controlled manufacturing to produce boards capable of standing up to lengthy use, and with sufficiently low failure rates.

Important Elements That Add Up To Great EMS Electronics Design

1 - Weave Density

Many newcomers to modern board design are surprised to learn that modern PCBs are layered. In fact, they can have dozens of layers, up to 50 or more. They alternate between high-resistance and low-resistance materials, so that multiple circuit lines can be stacked on top of each other. The high-resistance materials are what keep those lines from getting crossed by creating a barrier.

Generally, these materials are fiberglass and resin, using fiberglass weaves on top of resin surfaces. The issue here is that low-cost manufacturers, especially overseas, will skimp on the fiberglass. Their products have a very loose weave, leaving gaps with little fiberglass conducting the electrical current. This degrades performance, as well as introducing syncronization issues due to the uneven speed of line transmission.

2 - Precise copper etching

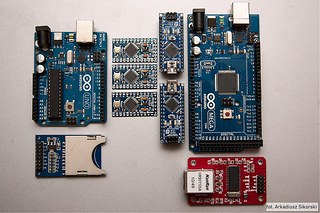

In many cases, the "adding" of copper lines to a PCB is actually a subtractive process: The board starts with a full layer of copper, which is then etched away to leave only the lines and connector areas needed for the circuit design. It's crucial that these lines be as smooth as possible. Jagged edges or uneven etching on the copper reduce reliability and introduce extra RF interference when the board is placed under a high load.

In many cases, this is plainly visible, even to the naked eye. Take a look at one of your boards sometime. If the edges of the copper wiring look jagged, wavy, or otherwise not-smooth, you may want to start looking for a manufacturer with higher-quality equipment.

3 - Prototyper vs Manufacturer Mismatches

This is another issue we see crop up more and more: When a company is using Manufacturer A to create prototypes and Manufacturer B to mass-produce the final build, it is absolutely essential that B be able to provide the same level of precision and worksmanship that A can. We've seen far too many situations where a great prototype has given way to a poor product, because the full-scale manufacturing run couldn't match the prototype.

Frankly, the best solution here is usually just to go single-source. When a company has the capability to go straight from prototyping to a full run, that eliminates guesswork as well as the redundancies involved in hiring two separate manufacturers.

4 - Cleanliness / Ionic materials

When dealing with high-RF EMS electronics design, cleaning the board after production should involve more than just spraying it with water and hoping for the best. Even microscopic specks of ionic materials - natural insulators - can have significant impact on the final speed and reliability of PCBs.

Higher-quality manufacturers have equipment which tests the conductivity of the board throughout the cleansing process, which allows them to know when a board is sufficiently clean. Without this sort of qualitative assessment, the cleaning process becomes guesswork.

Is your EMS electronics manufacturer able to keep up with the demands of modern tech? Contact ZenTech today to learn more about state-of-the-art PCB design techniques.