Zentech continues to strive to meet the electronics industry's ever changing technological demands by implementing mid-board copper solutions. A recent article on electronicdesign.com outlines these challenges.

Zentech continues to strive to meet the electronics industry's ever changing technological demands by implementing mid-board copper solutions. A recent article on electronicdesign.com outlines these challenges.

Specifying Mid-Board Copper Solutions

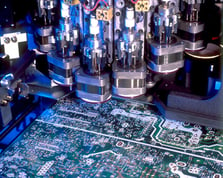

In a bid to satisfy continually increasing demands for higher performance, communications-equipment providers are moving to higher speeds on their internal printed-circuit boards (PCBs). Currently, 28-Gb/s signal rates are in design phases, with 56- and 112-Gb/s rates in the future.

The challenge is that PCBs aren’t well-suited to handling these higher speeds—they have issues with signal integrity (noise, insertion loss, amplitude, etc.), and that limits the distance PCB traces can reliably carry a high-speed signal. As a result, PCB designers must cope with board-layout limitations or move to higher-performing but more expensive PCB materials.

Mid-board copper (MBCu) solutions use connectors and cable assemblies to address this challenge. By bypassing the PCB, an MBCu solution delivers greater design flexibility, lower costs, and much better signal-integrity performance. With a cable that can extend to any component inside the box or even to external devices outside the box, an MBCu connectivity solution turns a two-dimensional circuit-board design into a 3D space where far more configurations are possible.