For every single process put into your product by an electronics manufacturing company, there is a specialized part to make sure it works. Every circuit board and other electronics that go into bigger machines are all put together by parts that are included in every single part of the process, ensuring that everything works once it is completed and is in top notch shape for your client.

This also means that every single process employed to create your electronics need parts that are high quality and won't break in the middle, or beginning, of their life cycle. How can you ensure that all of the parts for every process are in working order and you're getting the most for your time and time? Working with a contract electronics manufacturing company with all of these right signs is a great start, first off.

Parts Sourced From Trusted Buyers

When it comes to manufacturing, the company you choose to put together all of your batch orders is normally sourcing all of their parts from another company that just handles all of the components that are put into electronics. Whether it's unfinished boards, screws, electrical parts or something else, the manufacturer needs to find buyers that they trust and in turn you trust.

Unfortunately, not all contract electronics manufacturing companies are sourcing from the same, reputable places. That means your parts could potentially be made with faulty parts that could instantly break and cost you thousands of dollars. This is a very serious issue that has happened to businesses before, almost putting them on the brink of bankruptcy and losing many loyal customers. Instead of dealing with such a mess, always remember to find a manufacturing company using parts that are from highly reputable companies or made within the United States.

Once you know the chain of parts and manufacturing that goes into your own parts, won't you feel more at ease? You will also have the confidence of knowing where exactly the parts are coming from that are going into your electronics, creating electronic solutions.

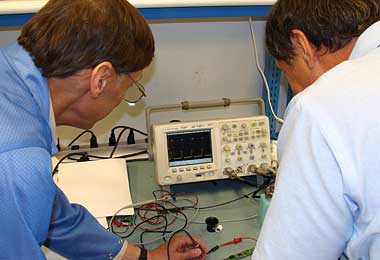

Specialized Testing & Designing

Does your manufacturer take the time to make sure every part of the building process is

built specially for your product? If they're taking the time--and energy--to make sure that your own process is built for you and not built to simply be as automated as possible to get  them another paycheck, then you know that each part of the process is given a special eye for detail and higher standards.

them another paycheck, then you know that each part of the process is given a special eye for detail and higher standards.

Your contract electronics manufacturing company is a very integral step in the entire design, creating, and implementing stages that your products go through. Shouldn't you take the extra time to double check that they're sourcing only the best parts and give the best attention of detail and personalization to your products?

Using The Right Tools

All of this also includes all of the parts of the process on their end, including machinery. If they aren't using the right tools to complete your order, then your products aren't going to be assembled correctly and have a much higher chance of breaking down.

Also, most manufacturers are automating most of the process, which is perfectly fine to an extent, but if they aren't properly setting the machinery before they put together your products, that's another risk that can mean less clients for you at the end of the day. Again, find a contract electronics manufacturing company that keeps you in mind when they're assembling your components. It's a lot easier than you might think.