Are you still using electronics manufacturers based around "through-hole" circuit board assembly? If so,you may be hobbling your own products!

Are you still using electronics manufacturers based around "through-hole" circuit board assembly? If so,you may be hobbling your own products!

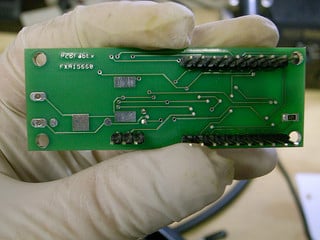

Through-hole circuits used to be standard in the industry, from the 1940s onward. The basic idea was very simple. The electronic components are mounted on one side of the board, with the wires threaded through matching holes to criss-cross the opposite side. If you ever played with breadboards in electronic hobbyist kits, that was a basic through-hole design.

However, there's a new method that's been around since the 1980s, but has recently become far more popular thanks to advances in the field: Surface-Mounting. Products made with surface mounted technology (SMT) are superior to older methods in most cases.

If you haven't looked into SMT methods, now is a great time to do so! With so much market competition in electronics right now, your products need every advantage you can give them.

Five Ways Surface-Mounted Technology Produces Better Products

1 - Less drilling.

One basic problem with through-hole mounting is that every hole has to be individually drilled into the circuit board before assembly can begin. This is an expensive and time-consuming process that also has a relatively high failure rate.

SMT can use pre-fab circuit boards with far less customization needed beforehand, and no need to drill into the board itself.

2 - Fewer wires.

SMT eliminates the need to have the back of the circuit covered in wiring because SMT utilizes a special kind of solder that also acts as glue. Simply placing the components onto the board "wires" them into place, with far fewer actual wires required. This generally reduces the chance of defects, as well as making repairs easier.

3 - Far greater component density.

You get a two-for-one benefit here. That special glue means that individual components can be smaller and more tightly-packed, since they require fewer wires connecting them.

Plus, of course, since the backside of the board isn't reserved for wiring, it can be used for components. SMT production facilities that support double-sided component placement can produce far smaller and more energy-efficient electronics.

4 - Automation-friendly assembly.

SMT processes are much easier to automate, since a lot of the detail work which would require human intervention is eliminated. There's no need for hand-drilling or custom laying of wires. For that matter, even the components are generally less expensive than those used in through-hole mounting.

The result is that SMT processes will almost always be cheaper for you than through-hole, especially whenpost-sale support and repairs are taken into consideration.

5 - SMT can combine with through-hole.

As we mentioned above, there are certain cases where SMT isn't as effective as the older technology. There are two particular issues with it:

-

The glue used melts under high heat. As such, components which will bear a high electrical load OR generate a lot of heat should not be mounted using SMT.

-

The glue is weakened by mechanical stress. The physical binding of through-hole components is much better for components where the user will be directly interacting with them, such as interface ports.

The good news is that you can mix-and-match without driving the price up or losing most of the advantages of SMT. For example, you could reserve part of the board for a through-hole mounted power transformer, while using SMT for the rest of the components.

Demand The Best For Your Electronics

With the electronics market so flooded, and consumers so accustomed to using online reviews to guide their purchasing decisions, a company simply cannot afford to release substandard products. Right now, the cream is rising to the top and everything else is simply sinking.

To learn more about how surface-mounting processes can save you a lot of money while creating better products, justcontact ZenTech today for a free consultation.