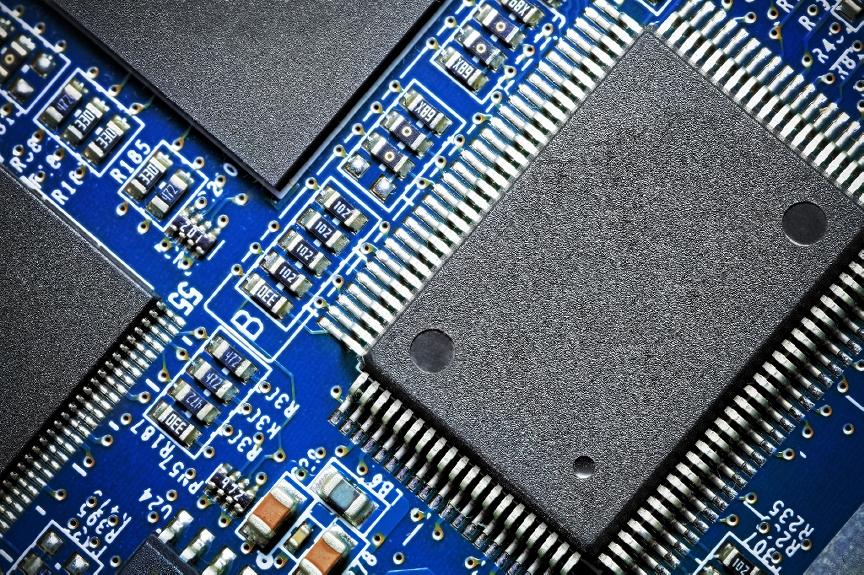

As a small to mid-sized electronics company, you may find yourself struggling, from time to time, to keep up with the large brands and businesses. While these "big fish" game players may be able to afford to employ a large staff of skilled designers and engineers, and stay on top of the latest and greatest assembly machinery, you may not have the same resources available to you. This is not an uncommon problem. To find success, many SMBs choose to contract the production of their PC boards out to a third-party manufacturer.

5 Characteristics Of A Great Contract Manufacturer

Topics: assembly solutions, boards, pc boards

Should PC Boards be Constructed with Through-Hole Methods or Surface Mount Technology?

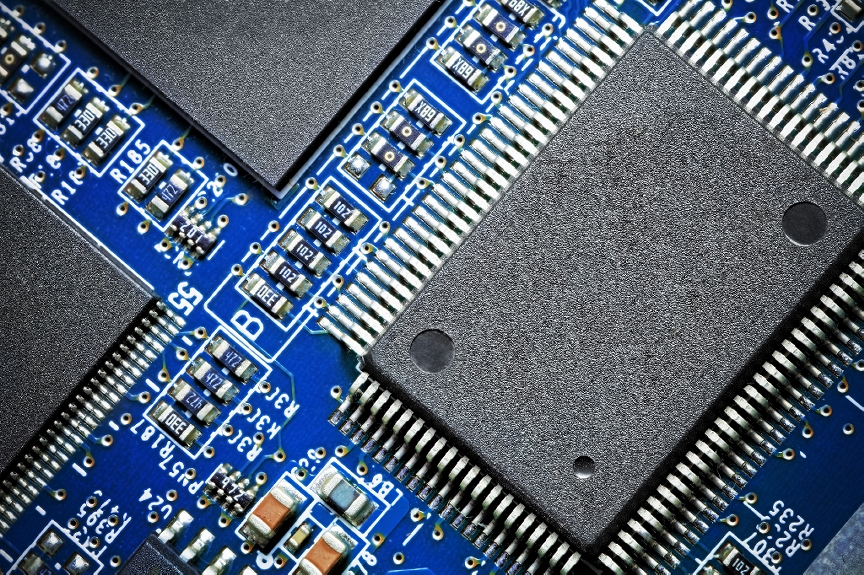

In order for your electronics business to attract and satisfy customers, you need to be focusing on the very basics of product design and manufacture: PC boards. As the demands of the consumer market change, and technological processes evolve, so must your way of thinking about printed circuit boards. Although it's true that through-hole mounting was the standard for PC board construction for years, surface mount technology (SMT) is the 'new kid on the block', and it isn't going anywhere anytime soon.

Topics: boards, PB board assembly manufacturer, pc board

Need Help Constructing Your PC Boards? 5 Characteristics of a Great Contract Manufacturer

As a small to mid-sized electronics company, you may find yourself struggling, from time to time, to keep up with the large brands and businesses. While these "big fish" game players may be able to afford to employ a large staff of skilled designers and engineers, and stay on top of the latest and greatest assembly machinery, you may not have the same resources available to you. This is not an uncommon problem. To find success, many SMBs choose to contract the production of their PC boards out to a third-party manufacturer.

Topics: contract electronics manufacturer, boards

Keeping the Production of PC Boards on American Soil

As technology continues to advance, consumers are increasingly interested in purchasing electronic gadgets that are dense, compact, fast, and above all, affordable. In order to meet these demands, many electronics companies are searching for ways to scale down their production costs, enabling them to lower customer price points while still earning a significant profit. Unfortunately, some of these companies are making the mistake of setting their sights offshore, in search of cheap labor in the construction of their PC boards.

Topics: boards, PB board assembly manufacturer, pc board