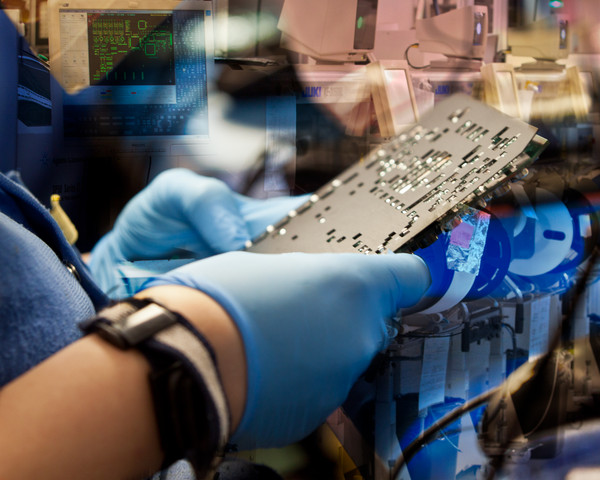

If you're not looking to repair defective equipment, and send out replacements instead, you could be throwing away a lot of money along with the circuit boards!

Proper Repair Services Will Cut Your Assembly Manufacturing Costs

Topics: assembly manufacturing, electronics repair services, electronic design

Electronic Design And Manufacture, What Services Are Involved?

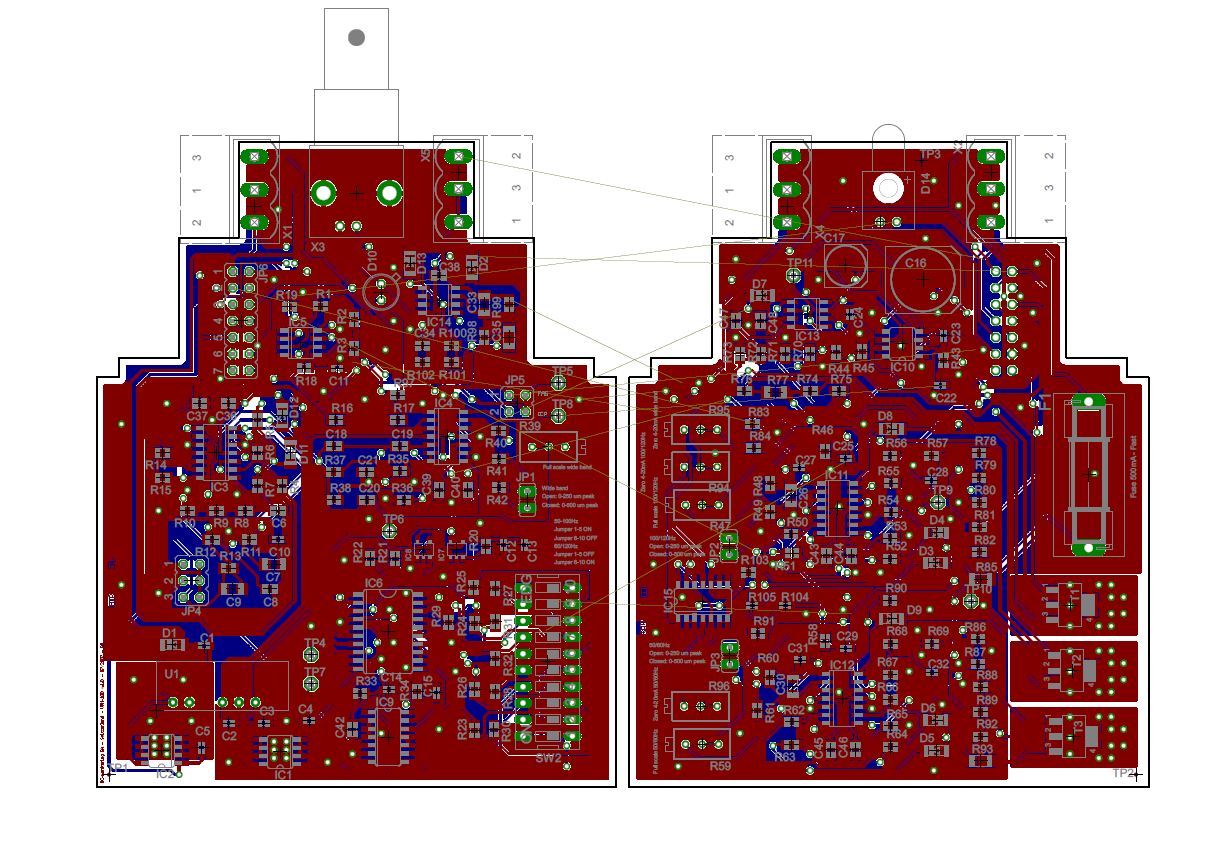

Could making the decision to contract with an electronic design and manufacture company help improve your business? Although you may think that you have all of your bases covered, you might be surprised to learn what a third party agency could do for you. Regardless of whether you are in need of complete design and build services, or if you just need a little assistance in fine tuning your processes, you could benefit significantly from a partnership with a contract manufacturer. Here's a quick guide to what you can expect from both the design and manufacture side of working with a third party contractor.

Topics: electronic design and manufacture, electronic design, design and manufacture services

EMS (Electronic Manufacturing Services) generally refers to companies that design, test, manufacture and sell electronic gadgets while offering a return/repair services or assembly of original electronic equipment. While this might sound as an easy task, it is a hard to achieve investment that once up and running will deliver quality assurance to a wide variety of customers and a go.

Topics: electronics manufacturing, ems electronics, electronic design

In the creation of systems that accomplish achieve great levels of performance without compromising their power consumption and size; there is the need to use well-designed electronic components. This pushes electronic component designers to come up with ways of designing and manufacturing new and more efficient components.

Topics: electronic design and manufacture, electronic manufacturing, electronic design