In today's economy, many businesses are the outsourcing assembly manufacturing to overseas companies as a means of saving money. But although this is initially less expensive, in the long run, it could cost you big time. Bootlegged products, shoddy craftsmanship, and failure to comply with safety regulations could lead to significant losses in revenue, a damaged reputation, and even fines or lawsuits. Because of this, it is wise to bring assembly manufacturing back home, and work with an American based electronic contract manufacturer that specializes in the design and production of complex electronics. Here are just five of the many reasons why doing this could work to your advantage.

1. Fast, Attractive Prototypes

When you are taking on a new client who is interested in the electronic products that you have to offer, they will want to see an example of your work before signing a contract and giving you their business. In some cases, your clients may need a device that is customized to their specific needs, which means that you will need to have the ability to quickly design and produce a workable prototype. A professional contract manufacturer will be able to help you to come up with a flawless design plan, and through a high-tech assembly manufacturing process, you can turn out the prototype fast. This will give your new client the assurance that you can work at high seed, while still creating a quality products and meeting their demands.

2. Catch Errors Quickly

An offshore company may utilize non-skilled labor as a cheap means of handling the assembly manufacturing process. Unfortunately, this means that hundreds of your products could be put together incorrectly, or with faulty parts before anyone notices. In fact, your device could actually end up on store shelves or shipped to your customers before the mistakes are detected. An experienced American contract manufacturer will be staffed with experts who will be able to prevent problems like these from happening. Skilled workers with a trained eye will be able to spot issues quickly and fix them to minimize losses and uphold your reputation.

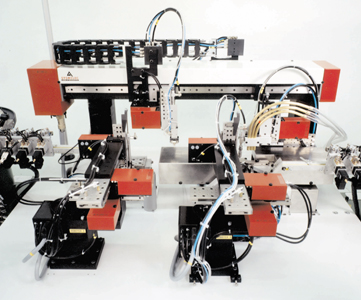

3. Utilize the Best Technology

When you have an assembly manufacturing partner, there's absolutely no need for your business to continuously try to "keep up with the Joneses" in terms of investing in better, more advanced equipment. Your contract manufacturer will keep their facility current with the latest and greatest machinery for producing electronics, so that you can take advantage of advanced machinery and precision robotics without spending a dime of your own.

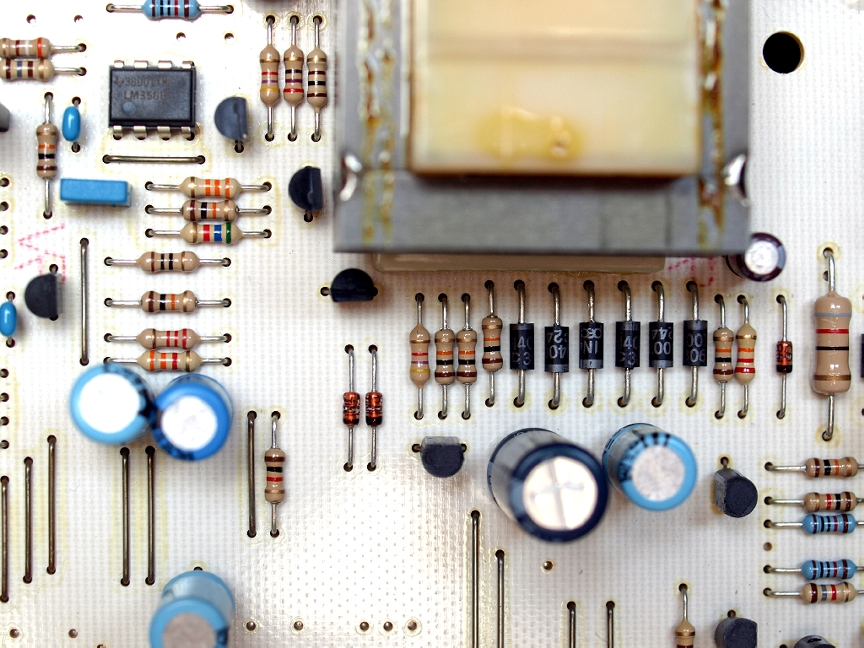

4. Testing and Quality Control

With the right contract manufacturer, you can count on the fact that your products will be manufactured correctly, from start to finish. Your partner will even test your completed devices in-house to ensure functionality and operability before sending them to your clients. This will ultimately prevent the losses and embarrassment involved with having to recall a product, or re-do an entire order as a result of overlooked flaws and mistakes.

5. Sell the Best Products

At the end of the day, your primary objective is to give your customers and clients the best possible electronics possible. If you are trying to handle large orders in-house, you may struggle to keep up with demand, which will lower the quality of your devices. On the other hand, we have already seen how outsourcing the assembly manufacturing process to an offshore location can be damaging to both your company and the end users.