A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 4 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

4 Reasons to Consider Hiring A Contract Manufacturing

Topics: contact manufacturers, American based product assembly, electronics contract manufacturing

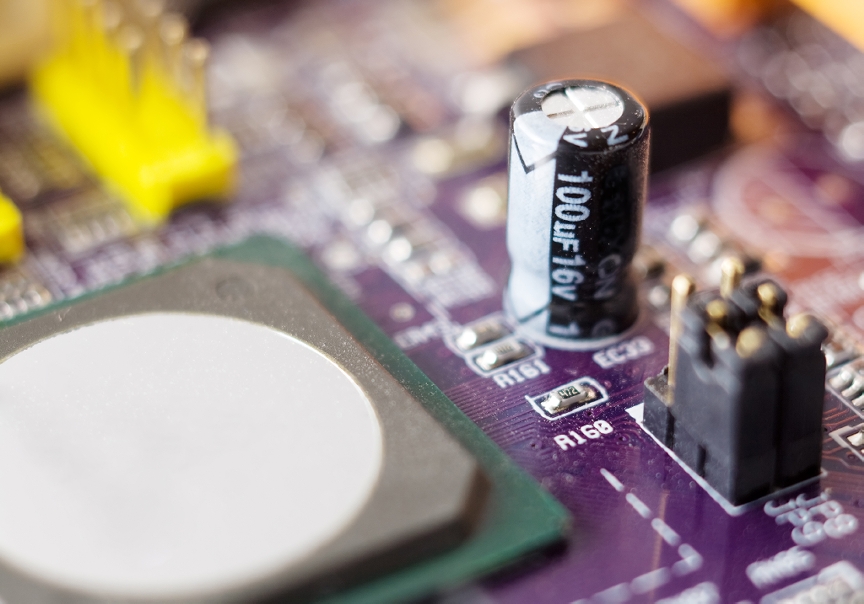

It's not uncommon for small to midsize electronics companies to seek out the assistance of a contract manufacturing vendor as a means of reducing the time, costs, and other burdens associated with the production of PC boards. Contract manufacturing businesses exist all throughout the world, providing companies like yours with many options. Unfortunately, while many offshore contract manufacturers offer lower prices than their American competitors, the quality of their boards are often subpar. But what is it, exactly, that makes American businesses better and sets them apart? This post will take a deeper look at why you should only consider partnering with an American manufacturing service.

6 Reasons to Hire American Contractors

Topics: assembly manufacturing, contact manufacturers, assembly manufacturer

How To Save Money by Hiring A Contract Electronic Manufacturer For Your Electronics Assembly

Topics: contact manufacturers, assembly electronics, Contract Electronic Manufacturers

Who Do You Trust For Your Electronic Assembly Needs?

For small to mid-sized electronic companies, making the decision to outsource their assembly electronic processes is a bit of a no-brainer. The cost to work with a third-party professional is often much less than it would be to hire a full team of skilled laborers, and the burden of purchasing and maintaining expensive equipment is removed from your shoulders. When you've got an excellent outsource vendor on your team, you can remain competitive with larger-scale industries and grow your business.

Topics: Contract Electronic Assembly, contact manufacturers, assembly solutions

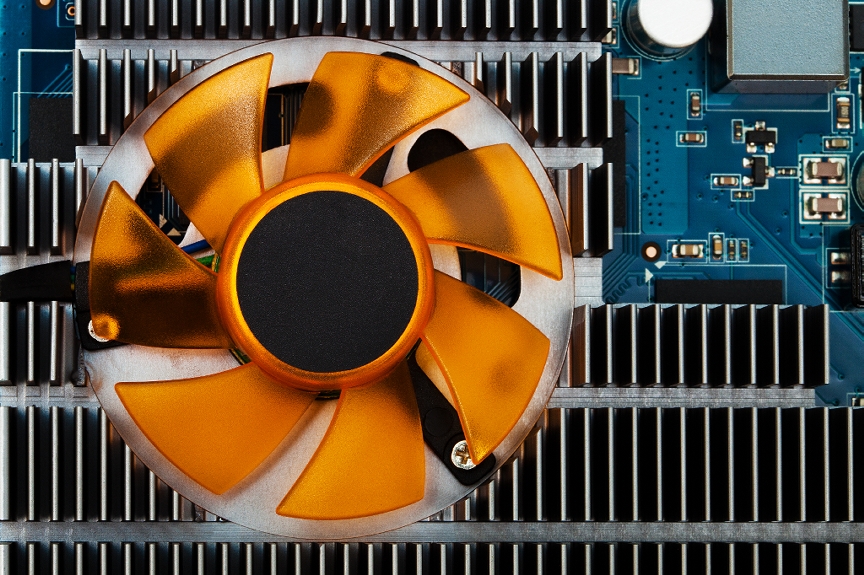

In case you haven't already noticed, the electronics market is getting more and more competitive with every passing year. It really doesn't matter what industry you're working in, either. Whether you're developing high-tech aerospace technology or complex communications devices, you've got to contend with an array of similar products and find a way to stand out. This requires you to be the absolute best in everything from design to marketing and everything in-between. The problem for smaller companies like your own is that you may not have the manpower or resources available to give equal attention to both the creative development side of production, and the actual process of device assembly. If this sounds familiar, contract manufacturers are the solution.

Topics: Contract Electronic Assembly, contact manufacturers, assembly solutions

Contract Manufacturers Play a Role Throughout the Production Cycle

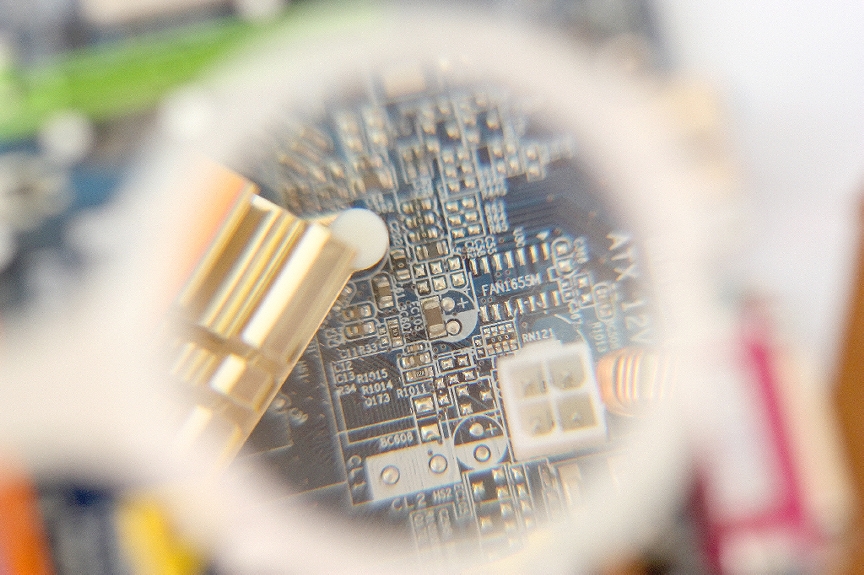

If you think that electronics contract manufacturers can do little more for your business than assemble your PC boards, think again. Many smaller scale electronics companies choose to work with a third party manufacturer because of their ability to remain involved throughout the entire production cycle. Regardless of where you are at in designing or manufacturing your products, you would be surprised by the level of assistance a contract vendor can offer. From start to finish, you can take advantage of just as much help as you require. Take a few moments to consider all that contract manufacturers can do for you; you'll wonder why you waited so long to work with one.

Topics: contact manufacturers, pc board assembly, PCB Repair Services

Contract Manufacturers: More Than Meets the Eye

Contrary to the name, contract manufacturers actually do a lot more than "just manufacturing". Although contracting with a third party electronics manufacturer is certainly ideal for businesses looking for a partner to shoulder the burden of production, the reaches of a great manufacturing company's services go far beyond that. In fact, those who make the decision to work with contract manufactures can reap a host of benefits. In this post we will explore some of the many services that the best third party electronics manufacturing businesses have to offer.

Topics: contract electronic manufacturing, Contract Electronic Assembly, contact manufacturers