Tightly-controlled inventory management and supply-line tracking is vital for a successful electronics manufacturing process. Are you doing everything possible to protect the parts that build your products?

Poor Supply Chain Management Will Cost You Money

Topics: Contract Electronic Assembly, inventory management, Contract Electronic Manufacturers

All-In-One Contract Electronic Assembly Lowers Your Costs

Sometimes, it just makes sense to keep your business under one roof.

Demand is higher for electronics today than ever before, and at the same time, electronics manufacturing requires ever-greater levels of skill and precision to deliver top-quality products. Older methods of outsourcing different aspects of production are having trouble keeping up with this, as the layers of sub-contractors often cannot coordinate sufficiently well to produce a truly high-quality end product.

Good Inventory And Supply Chain Management Is Vital For Modern Electronics

In most industries, good inventory management is important. In contract electronics, it's absolutely mission-critical for products to succeed.

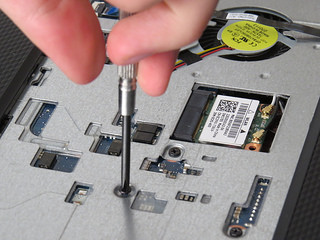

With contract electronics assembly, your inventory of parts and supplies plays a much bigger part in the overall success of a product, and of your business. A single bad $1 component can ruin a $100+ piece of electronics. This is an especially big issue with overseas assembly. There are plenty of stories of major businesses either not receiving the products ordered or discovering that counterfeit components had been used. Even the US Air Force fell victim.

Topics: contract electronic manufacturing, Contract Electronic Assembly

5 Ways You Can Reduce Your Electronic Assembly Expenses

These days, everyone is looking for new ways to scale back their spending and become a more profitable business. Although it may seem counter-intuitive, hiring a contract manufacturing company to assist you with the design and assembly of the PC boards for your products is one of the best ways for electronics companies to save money. How can spending money on a third party manufacturing service actually allow you to increase your bottom line and thrive? Here, we'll take a look at some of the many ways that a contract manufacturer can help you to achieve your business goals.

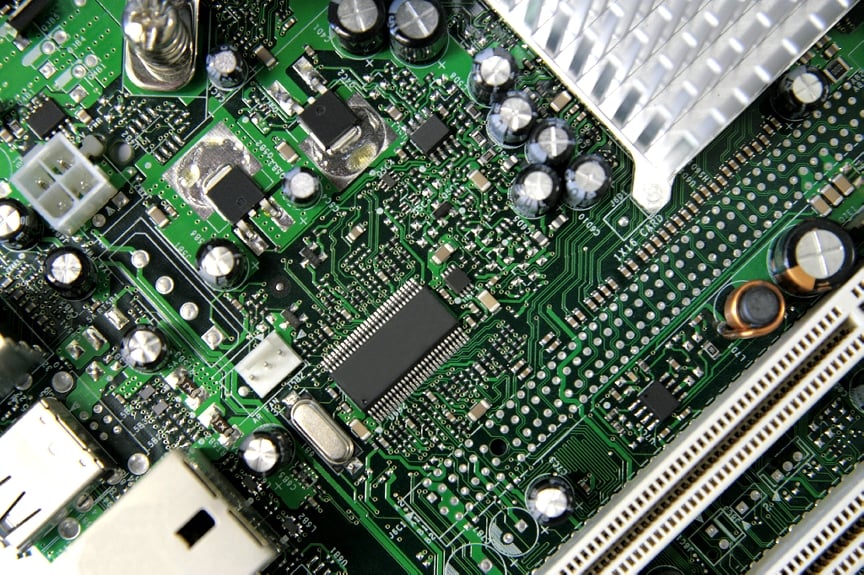

These days, electronics are everything. We are all wired in, whether for communication, work, or recreation. At the very heart of all of our electronics devices are the PC boards that allow them to operate and function as intended. As the years go by, the need for these boards to become more dense, more complex, and yet more compact has become even greater. As a result, electronics companies must understand and anticipate consumer needs so as to develop boards and products that will sell and satisfy. Despite the fact that most consumers will never give a second though to the boards running their devices, this is arguably the most important part of product development. Do you know what goes into the design and assembly of your PC boards? Read on to learn more.

Topics: pcb assembly, Contract Electronic Assembly, PCB Assembling

Don't Let Poor Inventory Management Cost You Money

Tightly-controlled inventory management and supply-line tracking is vital for a successful electronics manufacturing process. Are you doing everything possible to protect the parts that build your products?

Topics: Contract Electronic Assembly, inventory management, Contract Electronic Manufacturers

Who Do You Trust For Your Electronic Assembly Needs?

For small to mid-sized electronic companies, making the decision to outsource their assembly electronic processes is a bit of a no-brainer. The cost to work with a third-party professional is often much less than it would be to hire a full team of skilled laborers, and the burden of purchasing and maintaining expensive equipment is removed from your shoulders. When you've got an excellent outsource vendor on your team, you can remain competitive with larger-scale industries and grow your business.

Topics: Contract Electronic Assembly, contact manufacturers, assembly solutions

In case you haven't already noticed, the electronics market is getting more and more competitive with every passing year. It really doesn't matter what industry you're working in, either. Whether you're developing high-tech aerospace technology or complex communications devices, you've got to contend with an array of similar products and find a way to stand out. This requires you to be the absolute best in everything from design to marketing and everything in-between. The problem for smaller companies like your own is that you may not have the manpower or resources available to give equal attention to both the creative development side of production, and the actual process of device assembly. If this sounds familiar, contract manufacturers are the solution.

Topics: Contract Electronic Assembly, contact manufacturers, assembly solutions

5 Things An Electronics Manufacturing Service Can Do For You

Whenever a year comes to an end, it's a time for business owners to pause and reflect on what has, and what has not, been working for their companies throughout the course of the past 12 months. For many small to mid-sized electronics businesses, though, it may be easy to pinpoint problems, but not as easy to find solutions. You may be aware that your equipment is out-dated or that you're spending too much on supplies and warranty replacements, but you're not sure where the answer lays. Fortunately, a stellar electronics manufacturing service can provide you with all of the help that you've been looking for. With the new year now upon us, there's no better time than now to partner with a reliable contract manufacturer. Here's a look at 5 key things that an electronics manufacturing service can do for you.

Topics: contract electronic manufacturing, Contract Electronic Assembly, electronics manufacturing service

8 Things to Look for in an Electronics Manufacturing Service

Are you looking for a superior electronics manufacturing service to contract with in the new year? If so, you're probably already well aware that there are numerous businesses that offer design and manufacturing services for you to choose from. Being able to differentiate between the best manufacturers and those that are sub-par, though, can initially seem tricky. If you're not exactly sure what it is that you should be looking for, you may not even know where to begin in narrowing down your options. In order to help you make the best and most educated decision possible, we've put together these eight factors that you should insist upon before hiring an electronics manufacturing service.

Topics: contract electronic manufacturing, Contract Electronic Assembly, electronics manufacturing service