Tightly-controlled inventory management and supply-line tracking is vital for a successful electronics manufacturing process. Are you doing everything possible to protect the parts that build your products?

Poor Supply Chain Management Will Cost You Money

Topics: Contract Electronic Assembly, inventory management, Contract Electronic Manufacturers

What To Look For When Hiring Electronic Contract Manufacturers

Following the manufacturing boom of the 1990s through today, there's now literally a world of options in terms of hiring contract electronics firms. How do you choose between your options?

Picking the right partner is more essential than ever, if you want your electronics design to succeed. More products are being introduced into the marketplace more quickly, while both businesses and consumers continue to demand higher quality. Simply offshoring manufacturing to the lowest bidder can easily mean a product that's late to market, and with quality that's not up to par.

Manufacturers today have found ways to cut costs while simultaneously offering more services than ever before. You can get a lot more for your money, if you look carefully.

Topics: electronic contract manufacturer, Contract Electronic Manufacturers

Don't Let Poor Inventory Management Cost You Money

Tightly-controlled inventory management and supply-line tracking is vital for a successful electronics manufacturing process. Are you doing everything possible to protect the parts that build your products?

Topics: Contract Electronic Assembly, inventory management, Contract Electronic Manufacturers

EMS Electronics Create The Perfect Way To Bring Your Product To Market

With the explosion of Internet technologies and global shipping, there's a market for devices today that's unmatched at any time in history. Global demand for electronics is skyrocketing, and there's plenty of opportunity for a company to grab a piece of the market.

Topics: ems electronics, Contract Electronic Manufacturers, Electronic Manufacturing Solutions

How To Save Money by Hiring A Contract Electronic Manufacturer For Your Electronics Assembly

Topics: contact manufacturers, assembly electronics, Contract Electronic Manufacturers

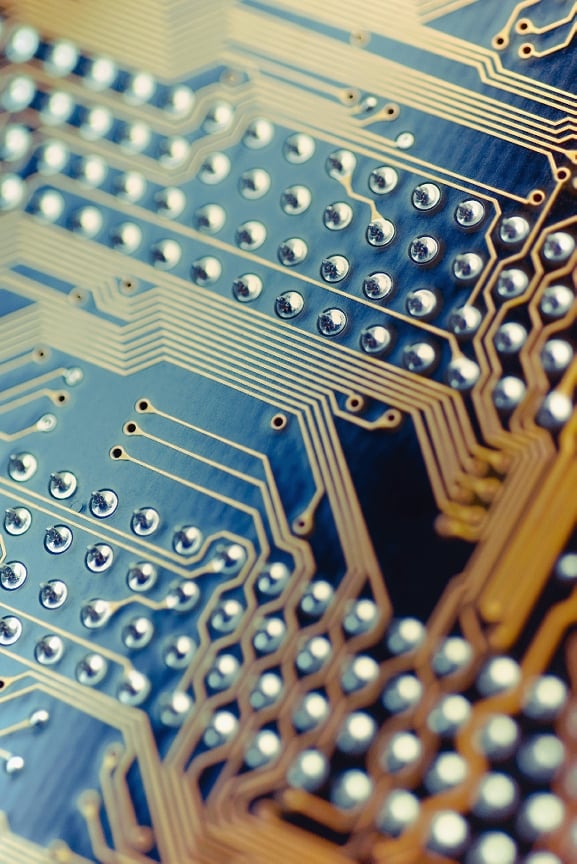

Electronics Manufacturing: From the Imagination to Store Shelves - It's All Interconnected

When you look at a PC board, what do you see? To the untrained eye, the makeup of these boards may seem chaotic and confusing. An electronics professional, on the other hand, would see a symphony of microchips, all in harmony with interconnected circuits. The completed board brings life to the technological gadgets, tools, and devices that all of us depend on each day, and its the perfect interconnection of the various components and circuitry formed by copper wire tracing that makes this possible.

Topics: electronic manufacturing, Contract Electronic Manufacturers, Electronic Interconnect Cables

American or Offshore: Choosing The Best Electronics Manufacturing Service

Many small to mid-sized electronics companies require the help of a third party manufacturer, at one point or another. But while you certainly have a great deal of options when contracting with an electronics manufacturing service, it's very important to be aware that not all outsource vendors are created equally. So who should you choose to work with? Will an overseas manufacturer provide you with quality PC boards and services, or would you be better off by sticking with an American company?

Topics: assembly manufacturing, Contract Electronic Manufacturers, electronics manufacturing service

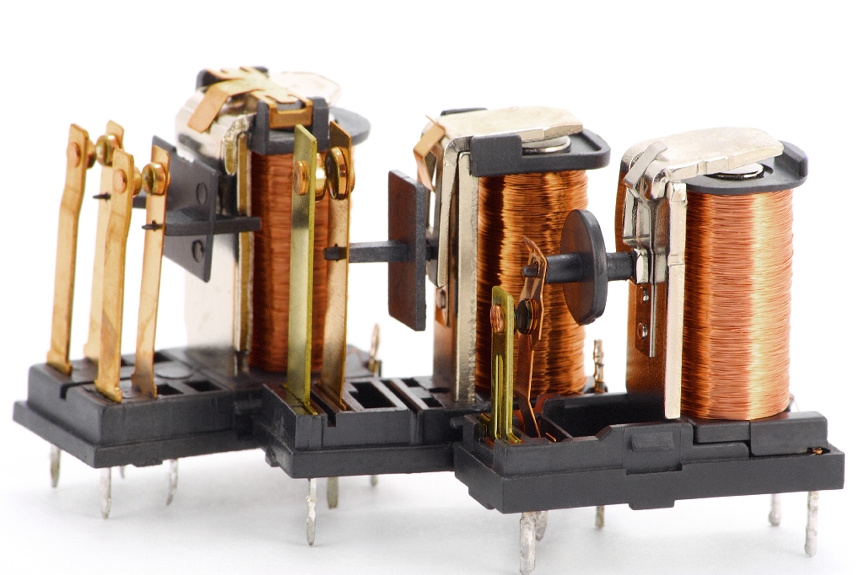

Contract Electronic Manufacturers Produce Precision, Efficiency

Is your small company struggling to keep up with its larger competitors? Although these "big leaguers" may have the resources available to efficiently produce precise and advanced circuit boards, you may be struggling to remain as competitive. Contract electronic manufacturers help to level the playing field so that you can stay on top of your game and provide high quality products more quickly and affordably than ever. Here's how:

Topics: contract electronic manufacturing, Contract Electronic Assembly, Contract Electronic Manufacturers

Why Are Contract Electronic Manufacturers Vital To The Economy?

In other posts we have explored the many ways in which contract electronic manufacturers are able to benefit businesses like your own, but what if we were to tell you that these operations also play a vital role in stimulating the American economy? In fact, these two points go hand-in-hand with one another. When contract manufacturers are able to assist electronics companies with their design and manufacturing processes, they actually contribute significantly to the economy. Here's a look at how contracted manufacturing companies do their part to help the USA.

Topics: electronic design and manufacture, PCB Design And Manufacture, Contract Electronic Manufacturers