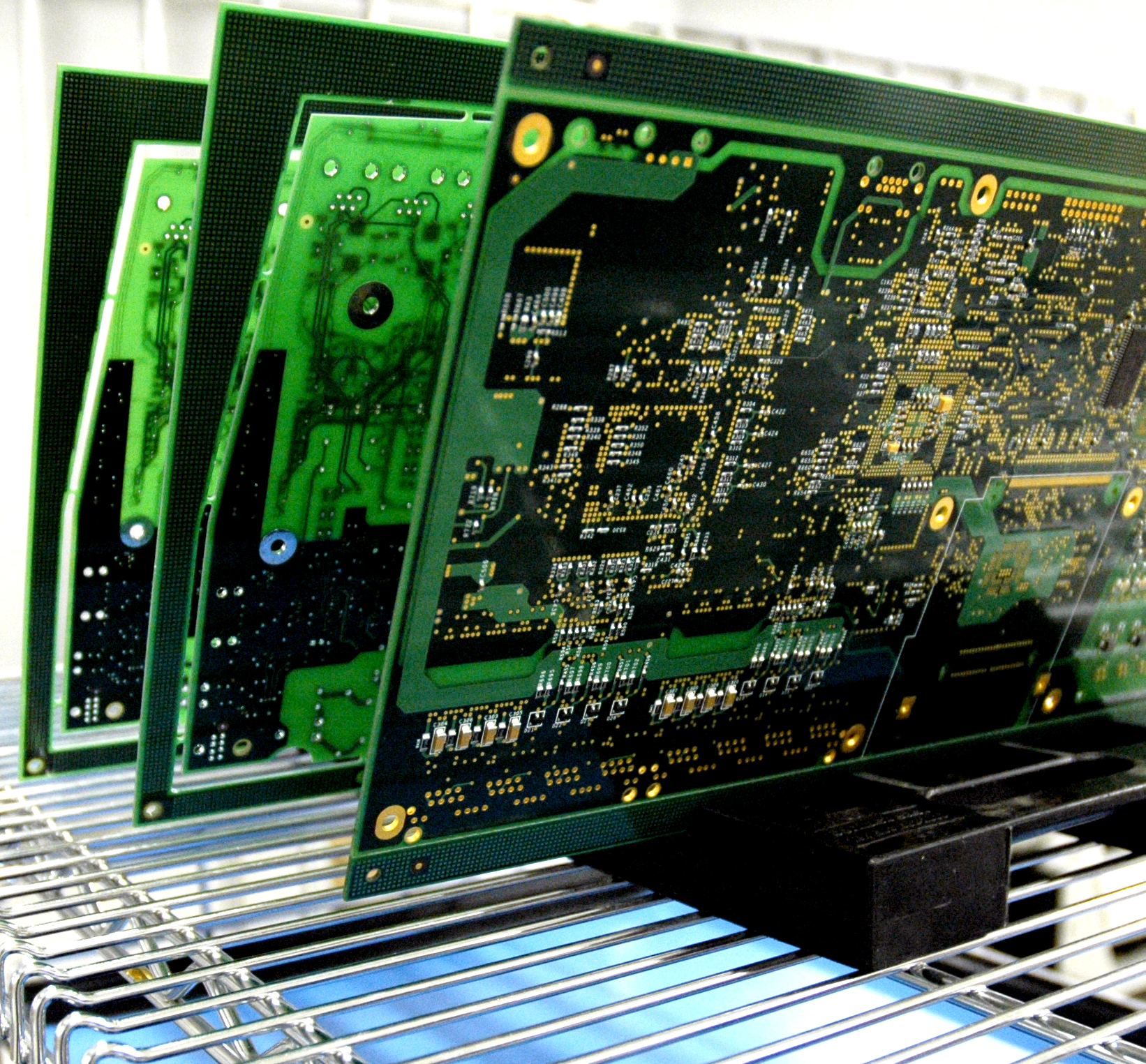

Likely because of the offshoring boom of the 90s and 2000s, there persists a belief that American-based manufacturing is too expensive to be worth considering - but nothing could be further from the truth. According to multiple studies into the matter, in the long term, costs associated with manufacturing in China and manufacturing in the USA are effectively at parity.

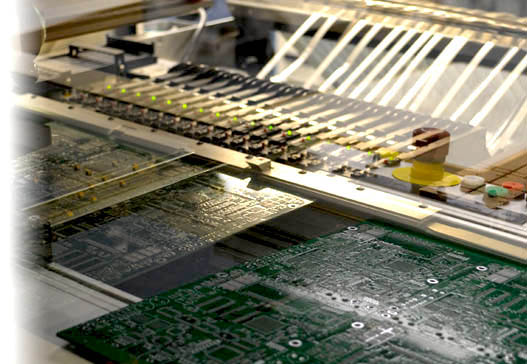

Moreover, American manufacturers have been hard at work updating their processes and competing on value rather than sheer cost. Sure, the up-front costs of a cut-rate overseas manufacturer will be lower than domestic... but that domestic manufacturer can offer plenty of services and long-term value that few, if any, overseas centers could hope to compete with.