No matter what market you're looking to enter, your electronics design needs to be rock-solid if it's going to succeed.

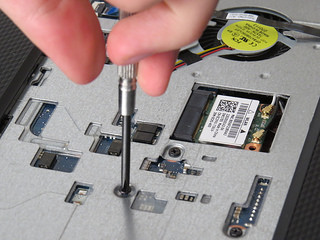

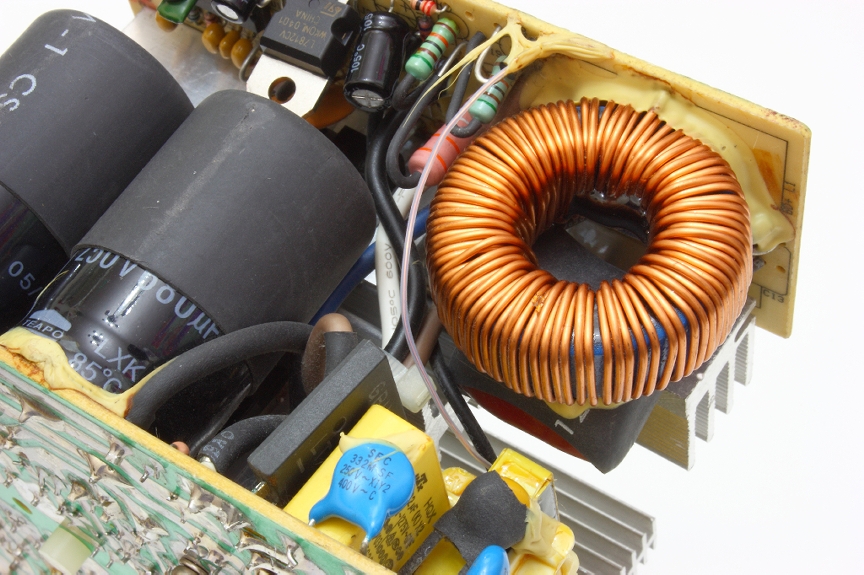

In-House Talent Makes All The Difference In Electronic Board Design

Topics: electronic board design, Electronic Board Design Services

In-House Talent Makes All The Difference In Electronic Board Design

No matter what market you're looking to enter, your electronics design needs to be rock-solid if it's going to succeed. The electronics manufacturing field is booming and still barely meeting demand, so there's plenty of room for great products to succeed.

But they have to be great products.

Companies still using "fire and forget" style outsourced electronic manufacturing services, which simply build to order, are taking big gambles with their product. Electronics today need to be more thoroughly tested, better-built, and better targeted to consumers if they're going to succeed.

Topics: electronic board design, Electronic Board Design Services

Custom Electronic Board Design Services Bring You More For Your Money!

Sure, there are a lot of cut-rate vendors in the world who will take electronic schematics and produce exactly what's on-paper... but that's rarely the best way to design and launch a new product. To create a successful piece of electronics today, you need an electronics assembler who can give you more for your money.

Topics: american electronics design services, electronic board design, Electronic Board Design Services