No matter what market you're looking to enter, your electronics design needs to be rock-solid if it's going to succeed.

In-House Talent Makes All The Difference In Electronic Board Design

Topics: electronic board design, Electronic Board Design Services

In-House Talent Makes All The Difference In Electronic Board Design

No matter what market you're looking to enter, your electronics design needs to be rock-solid if it's going to succeed. The electronics manufacturing field is booming and still barely meeting demand, so there's plenty of room for great products to succeed.

But they have to be great products.

Companies still using "fire and forget" style outsourced electronic manufacturing services, which simply build to order, are taking big gambles with their product. Electronics today need to be more thoroughly tested, better-built, and better targeted to consumers if they're going to succeed.

Topics: electronic board design, Electronic Board Design Services

Custom Electronic Board Design Services Bring You More For Your Money!

Sure, there are a lot of cut-rate vendors in the world who will take electronic schematics and produce exactly what's on-paper... but that's rarely the best way to design and launch a new product. To create a successful piece of electronics today, you need an electronics assembler who can give you more for your money.

Topics: american electronics design services, electronic board design, Electronic Board Design Services

Picking An Electronics Design Manufacturer Who'll Bring You Great Returns

With the boom in global electronics manufacturing and sales, it's little wonder that more companies are looking into electronic goods than ever before. Thanks to a world of manufacturing facilities, any design can be brought to market at surprisingly low investment costs.

However, like in any wide-open market, there's also a wide range of quality and services on offer. Too many companies simply look for the cheapest source, at least based on up-front costs, without considering the range of additional services that can ultimately reduce their TCO and boost the project's ROI.

Topics: assembly manufacturing services, american electronics design services, electronic board design

Tips For Getting Electronic Board Design Right the First Time

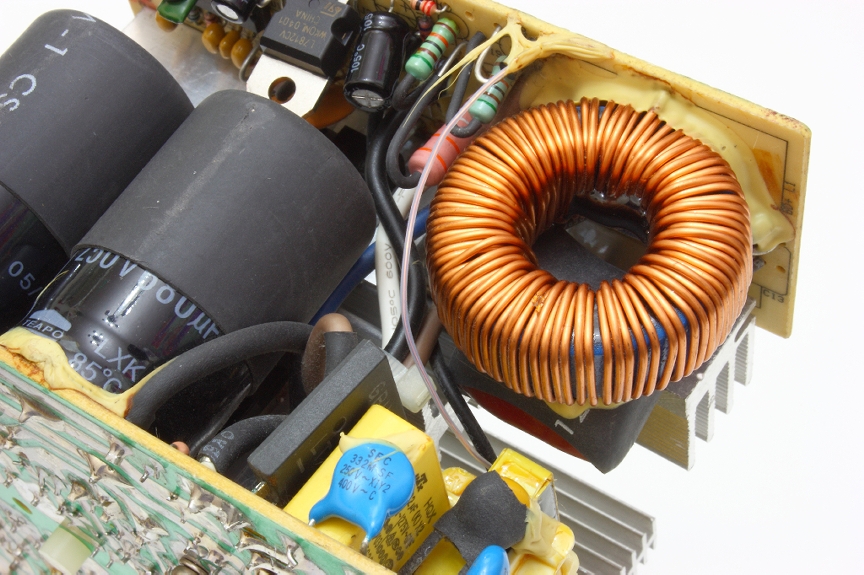

After countless hours of hard work, there's nothing more frustrating than discovering that your PC board design is flawed. A slight miscalculation can require you to backtrack as a result of sizing constraints. Even if all components fit, an error could cause the board to have operational deficiencies, and finding the root cause can be expensive and time-consuming. Wouldn't it be a lot easier if there were a for you to increase the odds of getting your design "just right" during your first go at it? Because we want to help you succeed, we've put together these tips and tricks for avoiding potential design iterations and expensive PCB re-spins.

1. Begin With a Space Study

Topics: pc board repair, electronic board design, pc board design

When To Seek Help For Electronic Board Design

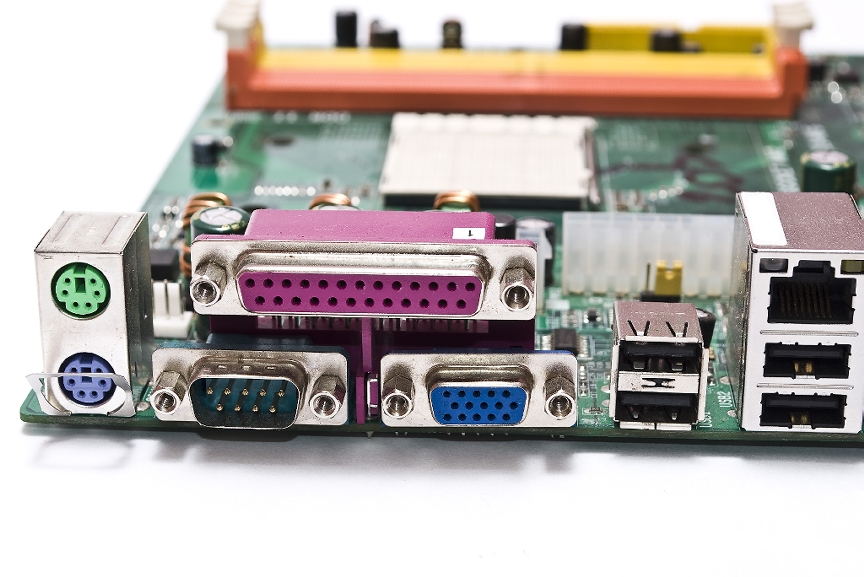

The electronics industry is one of the most competitive out there. As the years go by, technology is playing a bigger and bigger role in all of our lives, affecting the way that we work, learn, and communicate with one another. As a result, there is a huge demand for faster and better electronic devices and gadgets to meet consumer needs. In addition to wanting more features and higher levels of efficiency, though, these end-users are also looking for products that are smaller and lighter. In order to keep up with the market demand, electronic board design processes must evolve.

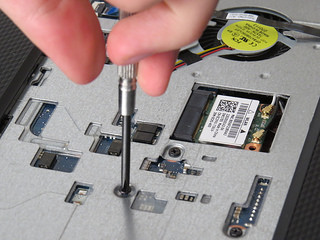

The smaller that electronics become, the more dense and compact PC boards need to be. This makes electronic board design significantly more complicated. Designers and engineers are given a very limited surface area to work with, and must overcome a number of obstacles in order to create boards that can function efficiently and serve their purpose. In some cases, this process can become too challenging for smaller electronics companies without the skills or tools required to do so. Is it time for you to seek out help from a third party? Here's a look at some of the most common scenarios in which you would benefit from having a contract manufacturer assist with your electronic board design.

Topics: pc board repair, electronic board design, pc board design

How Does Electronic Board Design Help You Create Your Product

Turn Your Ideas into Realities

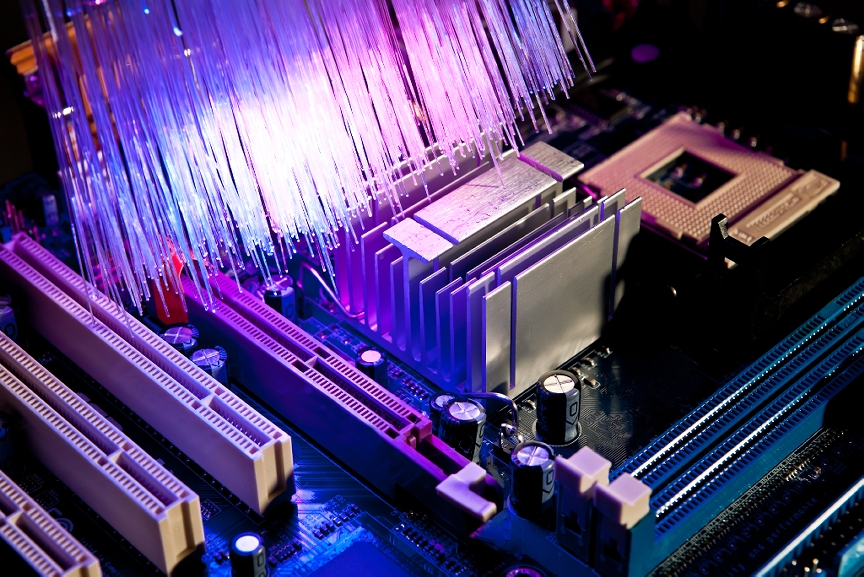

Your products are only limited by your imagination - especially when you have the best designers and technologies on your side. Skilled engineers with decades of industry experience are more than capable of bringing your concepts and ideas to life through concise, efficient design schematics. Paired with state-of-the-art design software, you can rest assured that the plans for your electronic board design will be a cut above the rest and will give you a competitive edge. Even if you are in the works of developing a brand new device or prototype, you will be able to get your plans set into motion faster. And if you're stuck on a particular problem, your manufacturing partner will be able to pinpoint the issues and come up with a timely solution.

Leave Nothing to Chance

From start to finish, the right contract manufacturer will take care to ensure that your electronic board design is truly flawless. A lot of careful thinking and planning goes into developing the schematics for your product so that it operates seamlessly. Be sure to work with a partner who is able to offer a full range of design services that span throughout the entire product life cycle, such as:

- Product requirements review

- System design

- Circuit design

- Mechanical design

- Embedded Software (firmware)

- Algorithm development

- Testing strategies

- Documentation creation/management

- Sustaining engineering

- RoHS Compliance

There is no reason that working with a contract manufacturing company for electronic board design should not help your business to save both time and money. Your partner's engineers should work diligently to ensure that all of your internal technical resources are utilized exactly when and where you have planned, for maximum value and efficiency. Additionally, your partner should be mindful of keeping your project on schedule and on point with your budget. By taking advantage of automated software programs and skilled employees, your project can be completed faster than had you chosen to go it alone, and errors can be avoided. In the long run, this will save the costs and hassle associated with troubleshooting for faults and redesign. In addition to all of this, experienced contract manufacturers may be able to cut down on the amount of materials required for your project's design, reducing your production costs even further. Multiplied by hundreds of boards, this can make a significant difference in your budget.

Constantly Improve Your Business

When you have help with the electronic board design process, the minds of your internal designers and engineers are freed up to develop bigger and better ideas. This means that you can be constantly moving toward higher goals and expanding your business. With a greater offering of products and high-tech devices, you will expand your market base and effectively grow your business. As your ideas become more advanced and the demand for your products grows, you will not be held back by a lack of experience, manpower, or technology, as your partner will be able to keep you moving forward.

The success of your business all begins with the initial electronic board design process. By taking the time to get it just right, you can grow your company and thrive. How could you benefit from professional electronic board design services?

Topics: contract manufacturing company, electronic board design, egineering design services