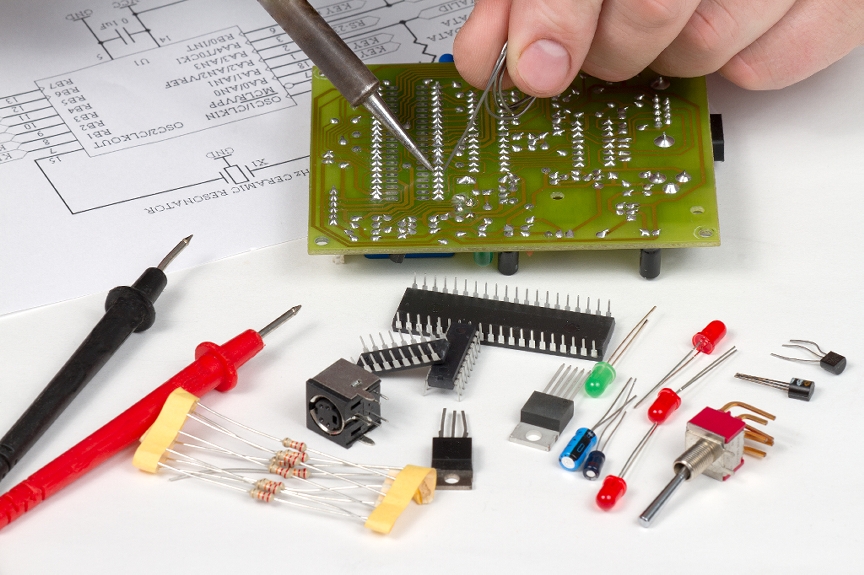

Technology is always changing, so what does that mean for technology manufacturers and sellers?

Current Trends In The Electronic Manufacturing Services Industry

Topics: electronic manufacturing, electronic manufacturing services industry, assembly electronic

Electronic Manufacturing Services Industry Is Booming, How You'll Benefit

After years of struggles, the electronic manufacturing service industry is making a huge comeback in America - and business is booming. As the consumer market becomes more and more dependent on smart electronic devices, those working within the high-tech sector can expect to be kept extremely busy. And with the United States and other countries around the world beginning to really emerge from the recession, the growth in this area will only continue.

Topics: electronic manufacturing services industry, Electronic Manufacturing Solutions, electronics manufacturing services

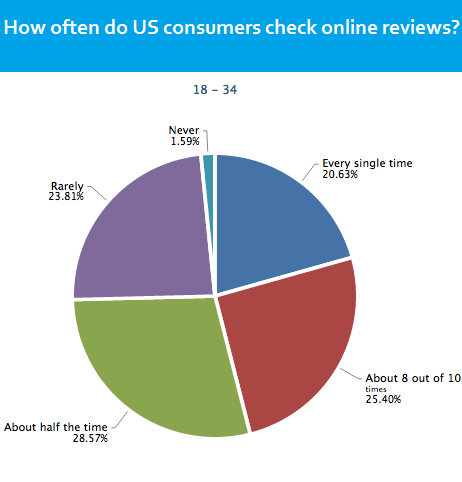

How To Find A Reliable Electronic Manufacturing Company

Is your business in need of a reliable electronic manufacturing company? Although you have plenty of third party companies that would be interested in getting your business, there are some that are more qualified than others. So how can you tell the difference? It's actually easier than you may think. By following these 10 simple steps, you can find an excellent contract manufacturer with total confidence.

Topics: electronic manufacturing company, electronic manufacturing, electronic manufacturing services industry

Creating Electronic Manufacturing Solutions

Like all other businesses, yours has probably been faced with challenges and obstacles from time to time. Although there are many instances in which these problems can be overcome in-house through a little resourceful thinking, it is important to have the ability to recognize when a solution cannot be found on your own. It is the companies who possess the foresight to anticipate issues and form alliances with a qualified contract manufacturer who generally find the most success.

Topics: electronic manufacturing services industry, Electronics Contract Manufacturer, Electronic Manufacturing Solutions