With the explosion of Internet technologies and global shipping, there's a market for devices today that's unmatched at any time in history. Global demand for electronics is skyrocketing, and there's plenty of opportunity for a company to grab a piece of the market.

EMS Electronics Create The Perfect Way To Bring Your Product To Market

Topics: ems electronics, Contract Electronic Manufacturers, Electronic Manufacturing Solutions

Electronic Manufacturing Services Industry Is Booming, How You'll Benefit

After years of struggles, the electronic manufacturing service industry is making a huge comeback in America - and business is booming. As the consumer market becomes more and more dependent on smart electronic devices, those working within the high-tech sector can expect to be kept extremely busy. And with the United States and other countries around the world beginning to really emerge from the recession, the growth in this area will only continue.

Topics: electronic manufacturing services industry, Electronic Manufacturing Solutions, electronics manufacturing services

Have A Problem? Electronic Manufacturing Solutions Can Solve It

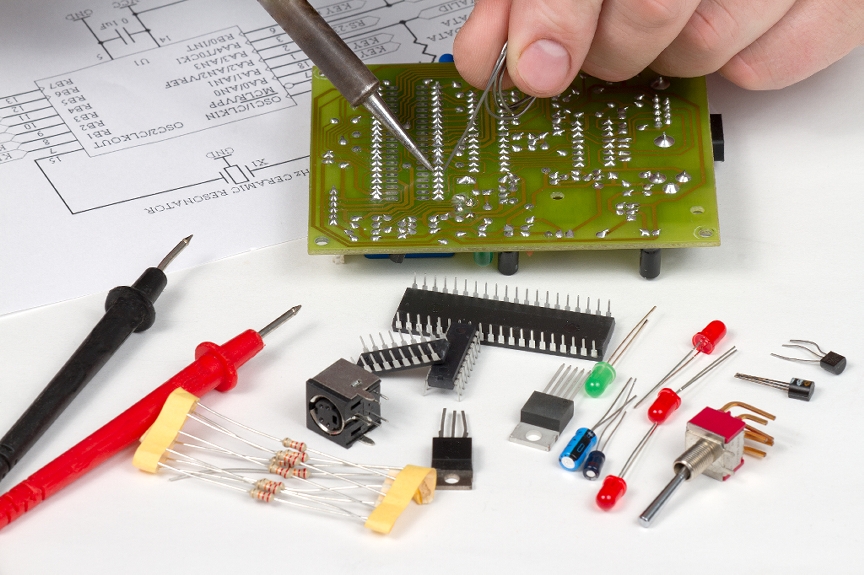

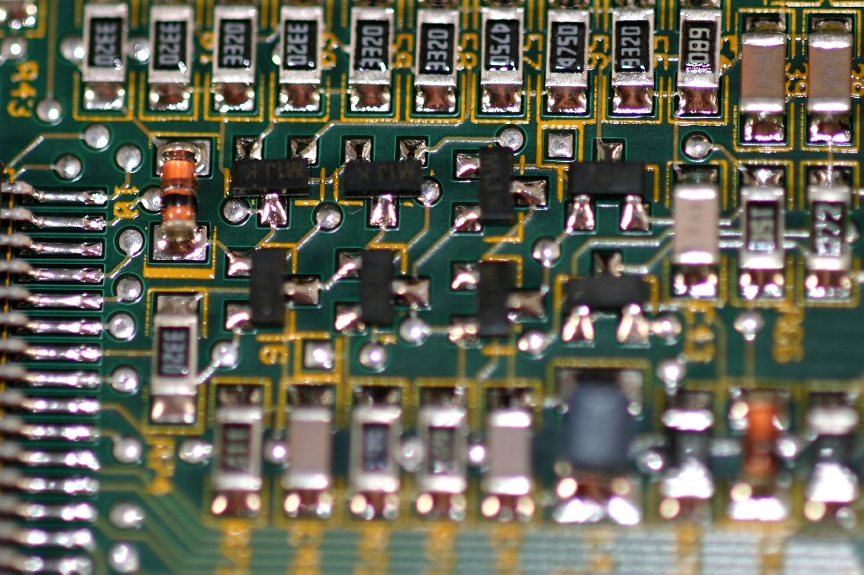

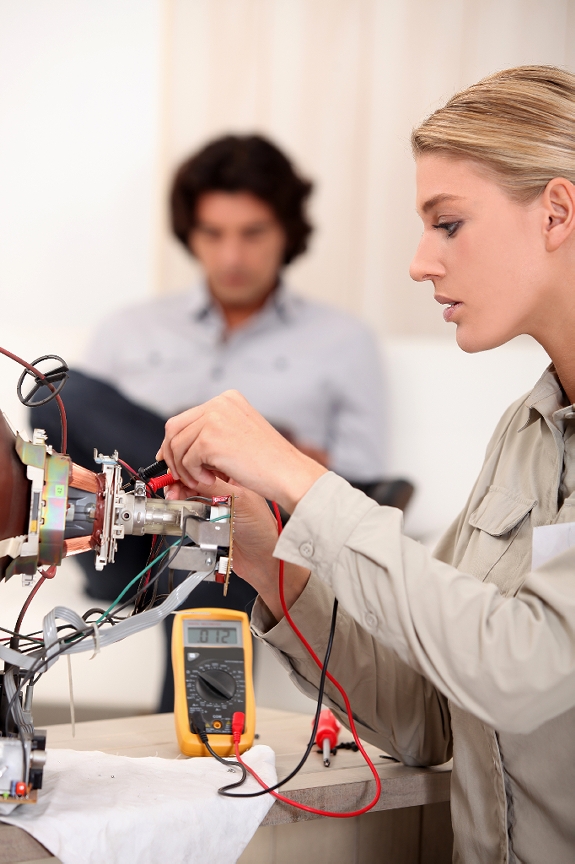

Every business faces problems from time to time, but the trick is to find the best and most cost effective way of resolving those issues. In some cases, you may find that this involves thinking outside of the box, and looking to a third party for assistance. Regardless of how big or small your electronic's company's troubles are, professional electronic manufacturing solutions can handle them for you. Here's a look at a few of the many problems that electronic manufacturing solutions can assist you with.

Topics: manufacturing services, PB board assembly manufacturer, Electronic Manufacturing Solutions

No Problem Too Big For Electronic Manufacturing Solutions

Regardless of the specific industry, every business faces its own unique sets of problems and challenges. For those in the technology sector, though, electronic manufacturing solutions can be found by contracting with a third party design and manufacturing company. No matter how big the issue may seem to you, a professional electronic manufacturing solutions provider can help you to overcome it and succeed. Here's a closer look at some of the most common problems in the electronics industry, and how they can be resolved.

Topics: electronic manufacturing company, Electronic Manufacturing Solutions, electronics manufacturing service

Creating Electronic Manufacturing Solutions

Like all other businesses, yours has probably been faced with challenges and obstacles from time to time. Although there are many instances in which these problems can be overcome in-house through a little resourceful thinking, it is important to have the ability to recognize when a solution cannot be found on your own. It is the companies who possess the foresight to anticipate issues and form alliances with a qualified contract manufacturer who generally find the most success.

Topics: electronic manufacturing services industry, Electronics Contract Manufacturer, Electronic Manufacturing Solutions

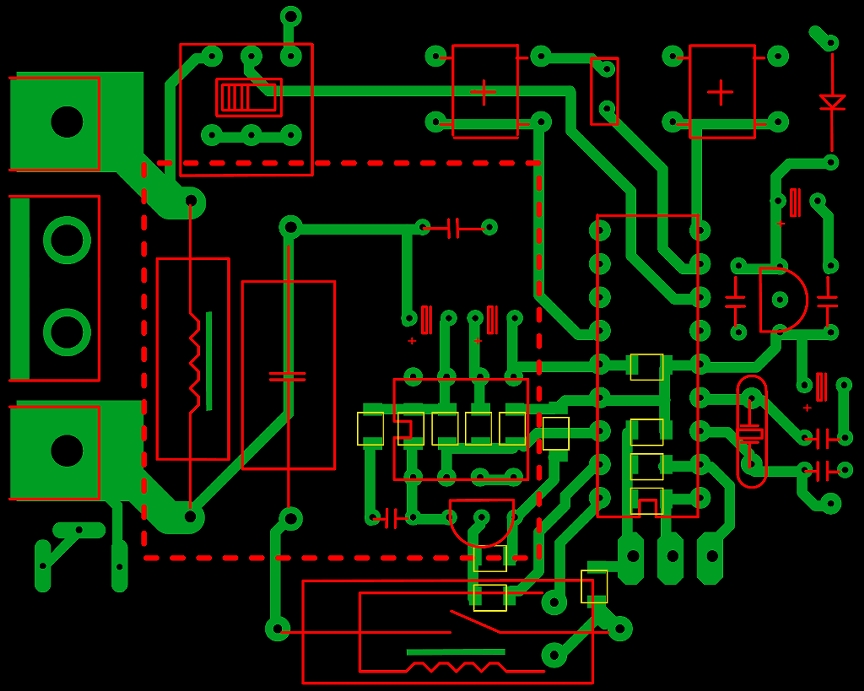

Finding new ways to make your manufacturing even more efficient and cost effective doesn't have to mean doing tons of paperwork and data gathering to find all of the perfect solutions. Sometimes those solutions are staring you right in the face and all it takes is utilizing them for your own projects. This is especially true for electronic manufacturing solutions, as people continue to rise the demand of electronic manufacturing and practically everything continues to become dependent on electronics.

Topics: contract electronic manufacturing, pcb assembly, Contract Electronics Assembly, Electronic Manufacturing Solutions