From time to time, we all need a little bit of help. As a business owner, though, you may tend to pride yourself on your independence, and have a strong desire to keep all of your processes in-house. But what if soliciting design, assembly, testing, and fulfillment services could actually help you to grow your company an enable to you bring in more cash? That would probably grab your interest, and it has, indeed, peaked the curiosity of other small to midsize electronics businesses. A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 6 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

7 Reasons Contract Manufacturers Help You Stand Out

Topics: assembly manufacturing, electronics contract manufacturing, assembly manufacturing firm

4 Reasons to Consider Hiring A Contract Manufacturing

A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 4 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

Topics: contact manufacturers, American based product assembly, electronics contract manufacturing

How Contract Manufacturers Help You Stand Out

From time to time, we all need a little bit of help. As a business owner, though, you may tend to pride yourself on your independence, and have a strong desire to keep all of your processes in-house. But what if soliciting design, assembly, testing, and fulfillment services could actually help you to grow your company an enable to you bring in more cash? That would probably grab your interest, and it has, indeed, peaked the curiosity of other small to midsize electronics businesses. A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 6 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

1. Knowledge & Experience

Topics: assembly manufacturing, electronics contract manufacturing, assembly manufacturing firm

What Services Does An Electronic Contract Manufacturer Provide?

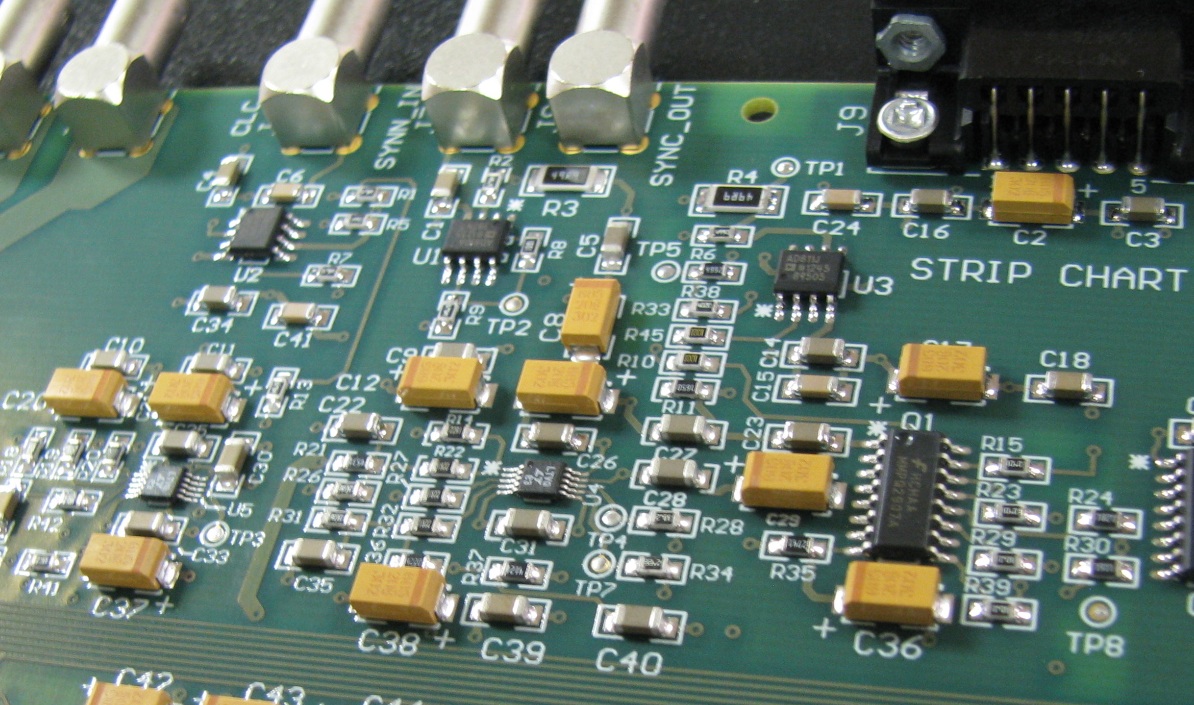

Whether your electronics business is thinking about seeking out help, or if you already use a third party service, it is very important that you know how to get the most value from your relationship with an electronic contract manufacturer. Although overseas partnerships may offer little more than mediocre product assembly, a qualified and professional service will be able to assist you in numerous areas. To ensure that you enjoy the most benefit from your outsourced help, here are several services that you should expect from your electronic contract manufacturing company.

Assistance with product design

Efficiency during the design phase is crucial to ensuring that your project goes smoothly. In order for your business to develop a product that your customers will be satisfied with, your team must take the time to carefully understand consumer demands and craft an electronic device that will be able to handle numerous functions while still being relatively simple to operate. Unfortunately, this often proves to be more challenging than it sounds.

Topics: electronic contract manufacturer, electronics contract manufacturing, state of the art equipment

Electronics Contract Manufacturing: Simple Yet Complex

Because the majority of the population relies upon the use of electronics each day, it is becoming increasingly important for these devices to be user-friendly. Most people want to be able to utilize light, compact technology that will allow them to accomplish multiple tasks in a relatively simplistic manner. But even though the goal of manufacturers is to develop simplistic products for their end users, the design and production process still remains quite complex. As such, a growing number of companies are beginning to turn to electronics contract manufacturing services for help in developing high-quality tech that will please the masses. Here's a quick look at what goes into developing even the most simplistic units, and why a bit of outside help is often needed.

Four Complex Steps Involved in Creating Simple Electronics

1. Understand consumer needs

It's been said that you can't please everyone all the time, but when you're developing technology for a large group of end-users, you've got to give it your best shot. The first step to developing an electronic device that will be profitable for your business is to take the time to learn exactly what it is that your target audience wants and needs. Although this may sound like a simple enough task, you may find yourself quickly becoming overwhelmed by the many demands of your market. This is where the assistance of an electronics contract manufacturing company may come in handy. With superior electronics design and production experience, your business partner may be able to help you to find ways to condense and consolidate consumer desires, making your product less costly to create, and more desirable to your customers.

2. Design multi-functional devices that's easy to use

Once you've got a strong, working idea of what it is that your product will actually need to be able to do, you've got to find a way to make it simple for your customers to use. Although your team may have the intelligence and skills required to understand and design extremely complex technology, they may struggle with the ability to scale it back a bit and make it extremely easy for end-users to manipulate. If your engineers have hit any roadblocks, they may benefit from a new set of eyes. Your electronics contract manufacturing service can help to simplify the plans, resolve any issues, and make sure that your consumer market will be able to perform even the most complex operations with just a few clicks of a button.

3. Manufacture products that are tech-dense, but lightweight

Today's customers want electronics that are lightweight and small, so you must find a way to meet their demands. Unfortunately, working with tiny components and parts by hand can be very time-consuming, costly and difficult, and can result in human errors. At the same time, the cost to purchase robotic arms that could easily manipulate these components can be overwhelming for small to mid sized businesses. The good news is that a professional contract manufacturing partner will enable you to take advantage of robotics and other advanced technology to produce your devices faster and more precisely than ever before.

4. Test for functionality and user friendliness

Finally, you must always test your electronics before introducing them to the mass marketplace. In addition to performing an in-house check for functionality, it's also wise to gather a small test audience to determine how easy it actually will be for your consumers to learn how to operate your devices and perform tasks. Should there be any hiccups along the way, you'll need to go back and correct the issues so that your market will have the best possible response to your product. In order to solve these problems for the lowest cost and with the fastest turnaround time, it's wise to team up with your electronics contract manufacturing vendor.

Topics: contract manufacturing company, electronics design, electronics contract manufacturing