IPC's Validation Services Program has awarded an IPC 1791 Trusted Assembler and the IPC 610 QML (Qualified Manufacturers Listing) to Zentech Dallas, a wholly owned subsidiary of Zentech Manufacturing. Following an initial audit by IPC, Zentech Dallas joins Zentech Baltimore in the elite group of U.S. trusted sources and suppliers with these certifications.

Topics: contract manufacturing company, electronic PCB assembly, Electronics Manufacturing Services Industry, US manufactured products, Maryland PCB assembly, PCB manufacturing, electronics manufacturer

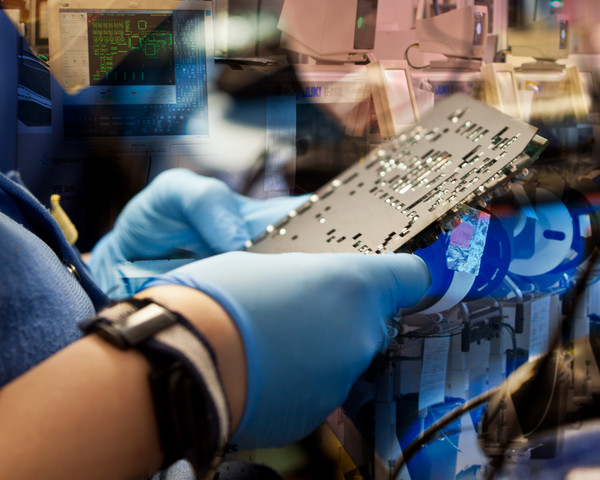

8 Things To Look For In An Electronics Manufacturing Service

Are you looking for a superior electronics manufacturing service to contract with in the new year? If so, you're probably already well aware that there are numerous businesses that offer design and manufacturing services for you to choose from. Being able to differentiate between the best manufacturers and those that are sub-par, though, can initially seem tricky. If you're not exactly sure what it is that you should be looking for, you may not even know where to begin in narrowing down your options. In order to help you make the best and most educated decision possible, we've put together these eight factors that you should insist upon before hiring an electronics manufacturing service.

Topics: Electronics Manufacturing Services Industry, electronics manufacturing service

Electronics Manufacturing Service: Making Older Factories New

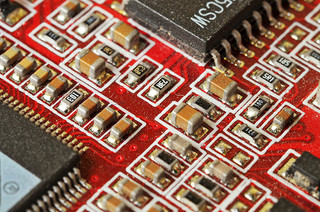

There are many factors to consider in electronics manufacturing service, and many have to do with the changing trends in technology, applying the latest methods of manufacturing, using the latest components and keeping up with greater complexities in design. Many Designers are attempting to meet the market demand in producing compact devices that are manufactured in the confines of a smaller volume yet hold all the features of former designs, a feat which is hard to accomplish without the right kind of manufacturing support and the flexibility to meet design complexities at a minimum cost.

Topics: manufacturing services, Electronics Manufacturing Services Industry, quality services

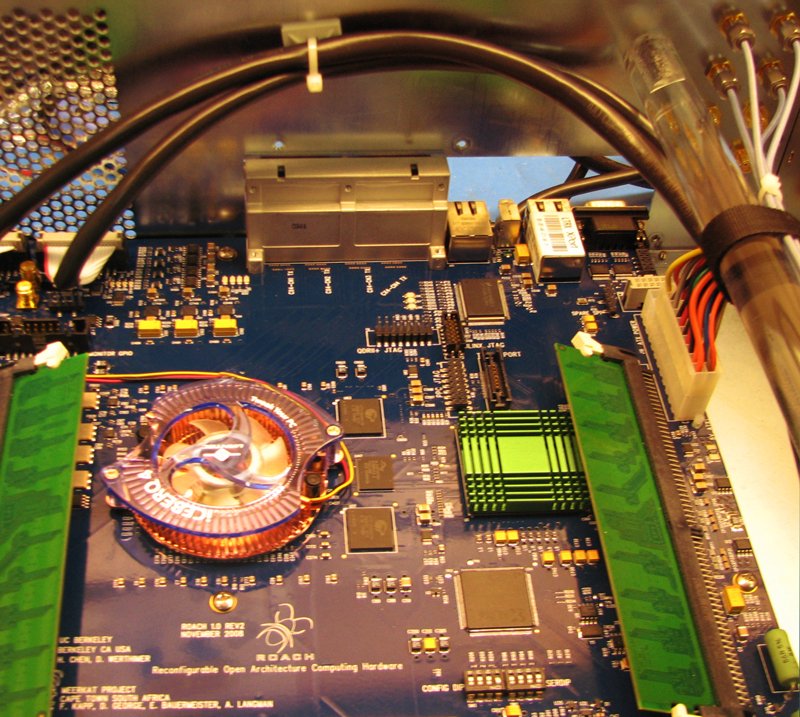

Electronics Manufacturing Service: Making Works Work Optimally

Making sure everything is working within your own works doesn't have to be a frustrating, time consuming and expensive endeavor that leaves you with a bad experience with your electronics manufacturer. You can get the right kind of service that fits to your needs, not to the mold of what the manufacturer tries to fit you into--all with saving money and still getting the same high quality you would find with a top notch electronics manufacturing service.

Topics: manufacturing services, Electronics Manufacturing Services Industry, quality services

Manufacturing Services Delivered Cost-Effectively

If your business is like many others, you may have taken a bit of a financial hit throughout the course of the past several years. It's no secret that the economy has been struggling which is why contract manufacturing services have become so popular. These types of services allow companies like your own to contract with a third-party manufacturer to design and/or produce goods and services for you.

Topics: manufacturing services, Electronics Manufacturing Services Industry, quality services

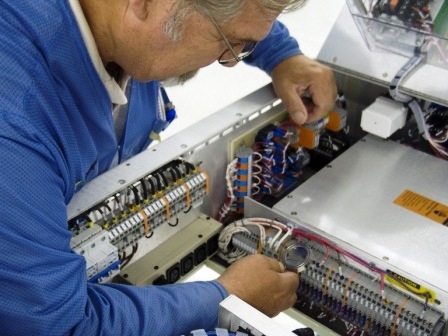

Manufacturing Services Designed For Every Industry

Most businesses tend to believe that all manufacturing services out there are more or less the same. The same packages, tiers, and everything that are given to all sorts of different clients that might be in completely different industries from one another. Unfortunately, that's a very bad assumption to believe because most manufacturers are here to cater to

your needs, rather than trying to mold you to a package that they think will pay them the most money.

Topics: manufacturing services, Electronics Manufacturing Services Industry, quality services