Electronics companies in the 90s and 2000s which chose to outsource their production work overseas often found themselves making compromises. The great distances and language barriers involved often introduced new issues that had to be worked around, often to the detriment of the product, the customers, or both.

One of the most obvious of these -and the most costly- is what happened to post-sale support in the wake of the offshoring boom. A big change was made to how a lot of companies handled warranty claims: Rather than attempting to repair the item, they simply sent out a new one every time.

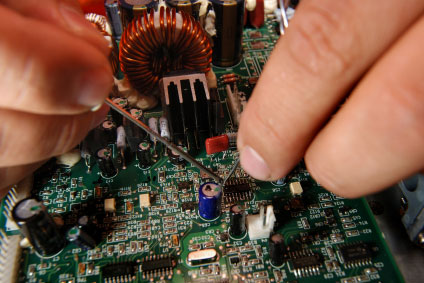

Granted, there are cases where this can be cost-effective, but when talking about products that can be hundreds of dollars on the shelf, it's incredibly wasteful to send out new ones when often a single low-cost component is to blame.