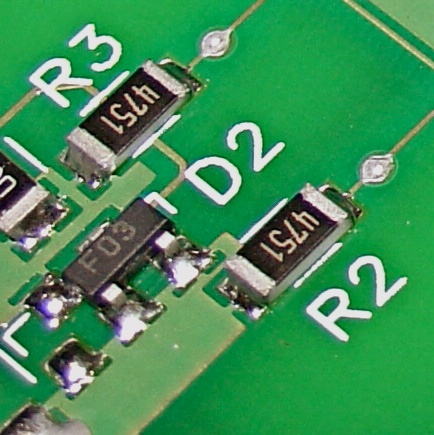

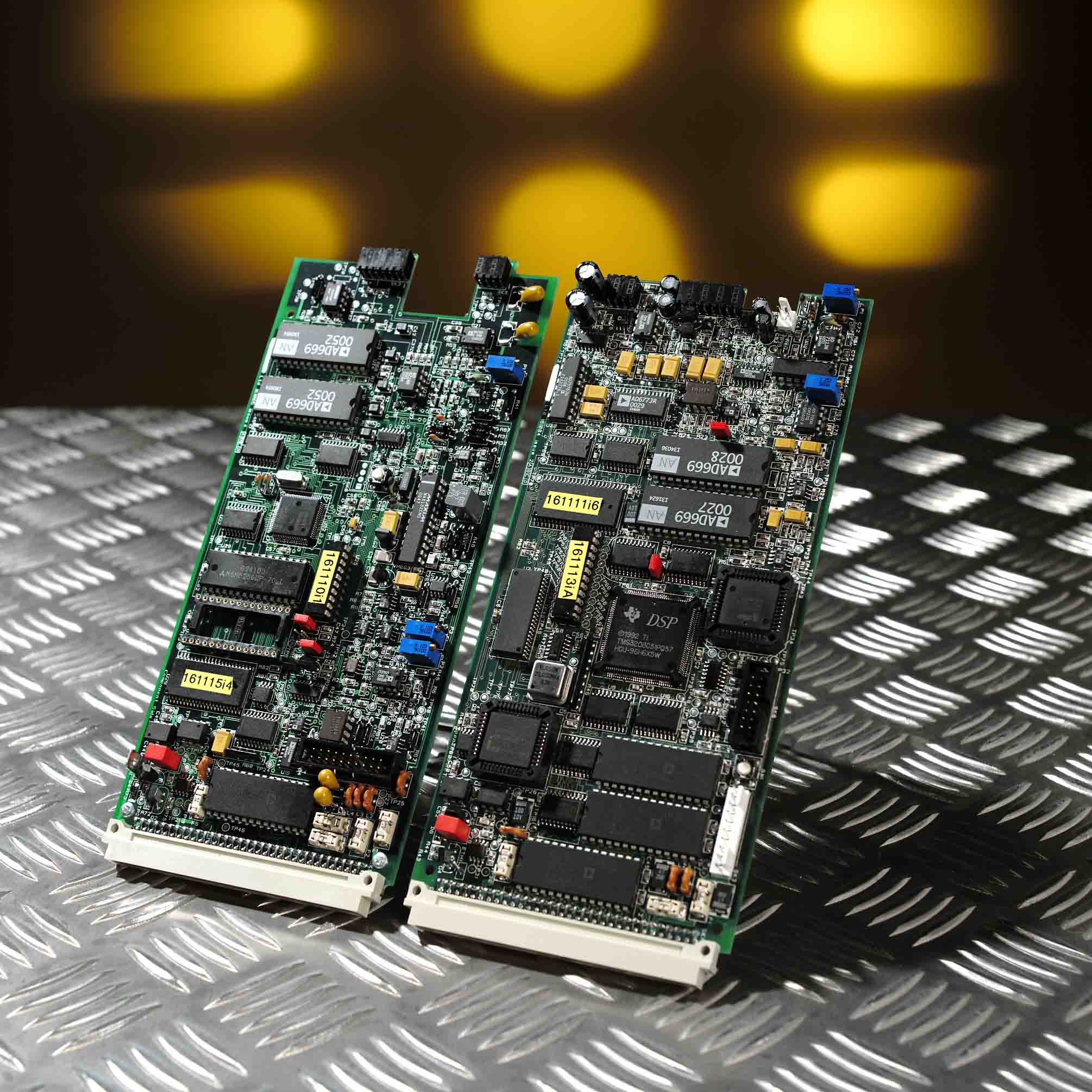

Circuit boards manufactured with Surface Mounting Technologies have revolutionized electronics manufacturing, thanks to their ease of construction and the much higher component density they make possible. SMT construction allows for devices which are smaller, more feature-packed, and (very often) cheaper to produce.

If you've ever wondered how it is that electronic devices can continually shrink in size, Surface Mounting Technologies (SMT) are largely to thank. This continually-evolving set of manufacturing techniques allows electronics to be created which are superior to alternative manufacturing methods in numerous ways.

What makes SMT different is that it allows individual components to be placed directly onto the circuit board, without the need for sending wires through to the other side.

What Is The Difference Between SMT and Through Hole Technology?

Surface mounted technology (SMT) has grown in popularity over the past few years and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Topics: SMT Assembly, smt manufacturing, through hole mounting

What Is the Difference Between Through Hole And Surface Mounted Technology

Over the past several decades, surface mounted technology (SMT) has grown in popularity and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Topics: smt production, smt manufacturing, surface mounted technology

SMT Production: Know The Basics Before You Start

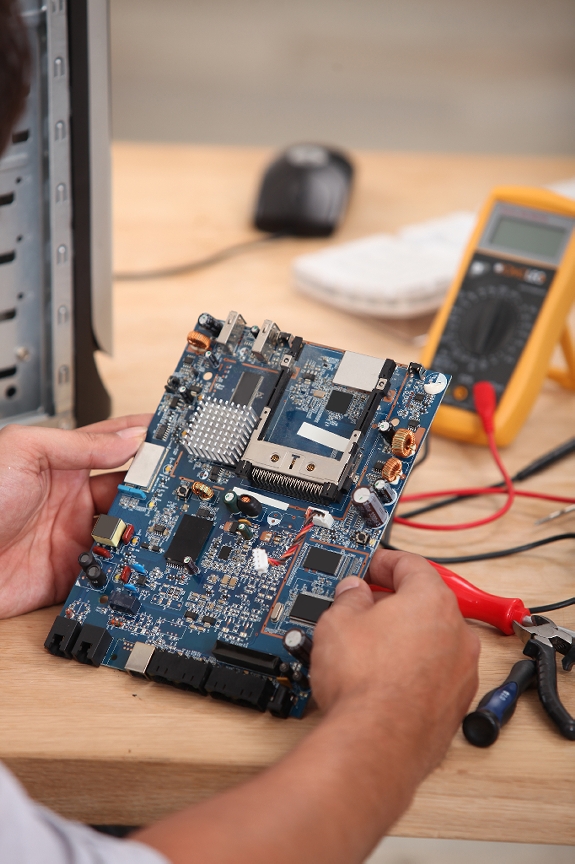

There are different approaches to mounting components onto a printed circuit board with each method having its own strengths and weaknesses. This brings up the need of understanding what a given circuit is expected to do hence going for an approach that will bring the best in terms or performance and durability out your circuit.

Topics: surface mount technology, SMT Assembly, smt manufacturing