When Shouldn't You Use SMT Production Methods?

Topics: assembly manufacturing, consumer electronics, smt production

Surface Mount Technology Creates Better Electronics Faster!

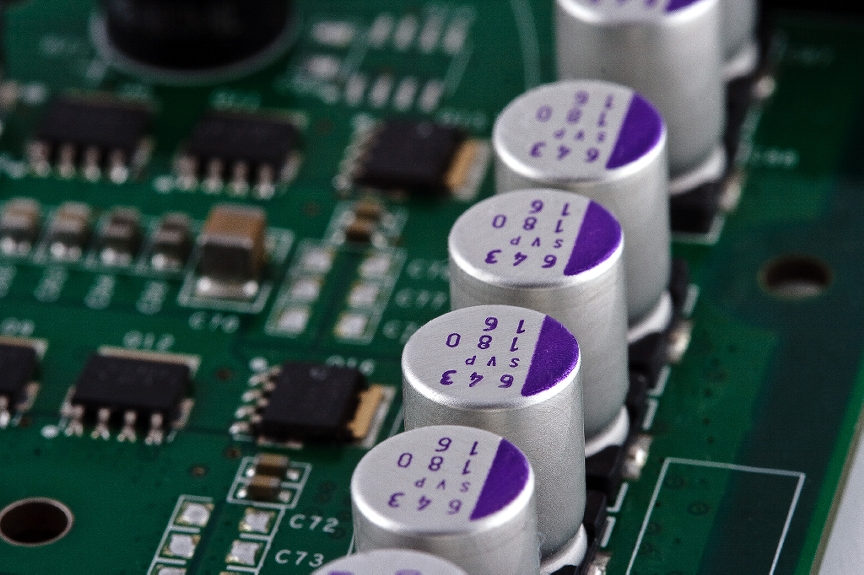

If your electronics assembly shop isn't using Surface Mount Technologies (SMT) in their processes, you're potentially losing out in numerous ways. While SMT production isn't a magic bullet, in most cases it creates smaller and more affordable products.

Topics: smt production, surface mount technology, assembly pcb

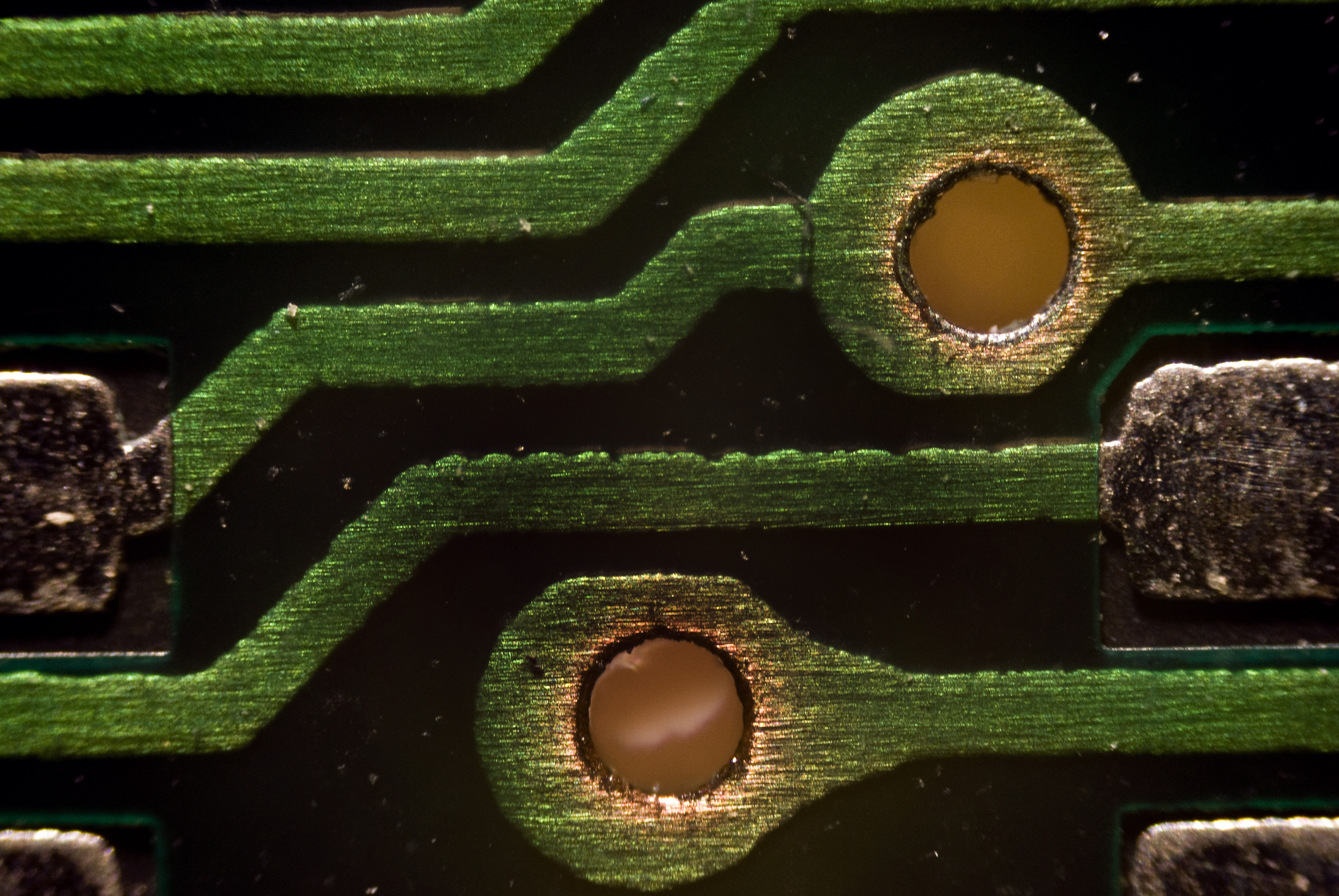

We all know what a stencil is, in the traditional sense. Children often make use of plastic stencil sheets in order to practice drawing shapes, while sign makers and other professionals are able to utilize them to create perfect letters. Here in the world of designing and manufacturing PCBs, though, we rely on laser cut SMT stencils. Although not too far off from the regularly recognized units, these laser cut SMT stencils are much more complex and simplify the process of PCB assembly by making it easier to apply solder paste to the board. This post will cover everything that you need to know about laser cut SMT stencils.

Uses

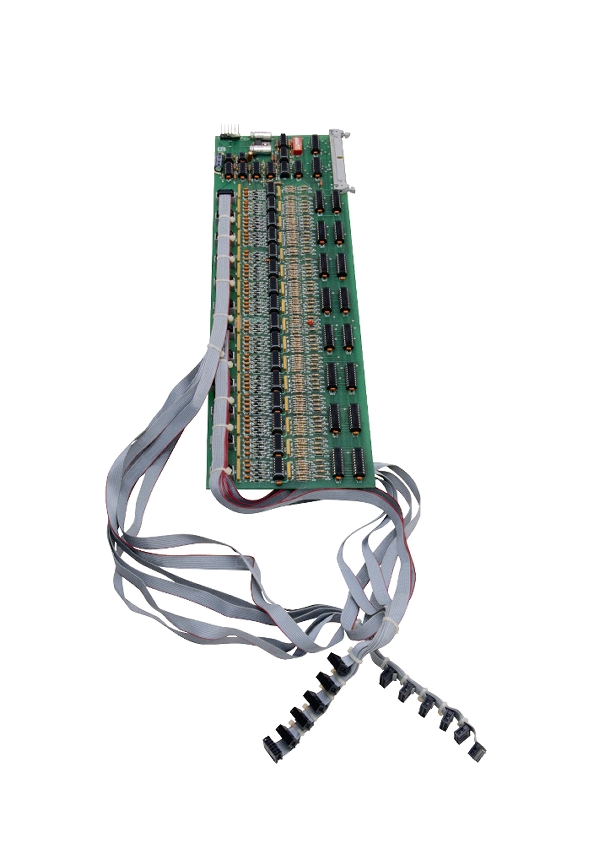

Throughout the electronics manufacturing process, a stencil may need to be used for a couple of purposes. First and foremost, stencils are a true life-saver when producing a board that relies on surface mount technology (SMT). Another instance when stencils are useful involves the use of automated component placement equipment (with the exception of hand-loaded prototypes. Why? Because it acts as an alternative to the requirement of hand soldering every single component.

Topics: smt production, surface mount technology, assembly pcb

Through Hole And Surface Mounted Technology - What is the Difference

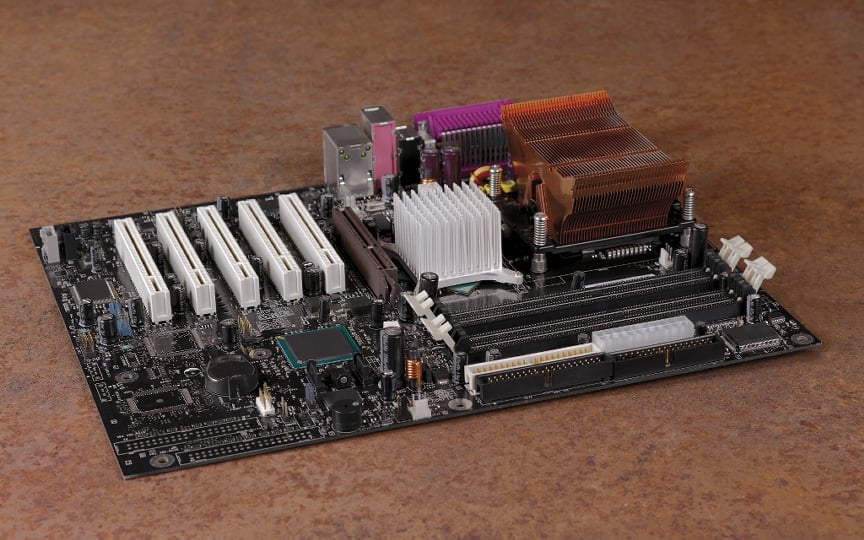

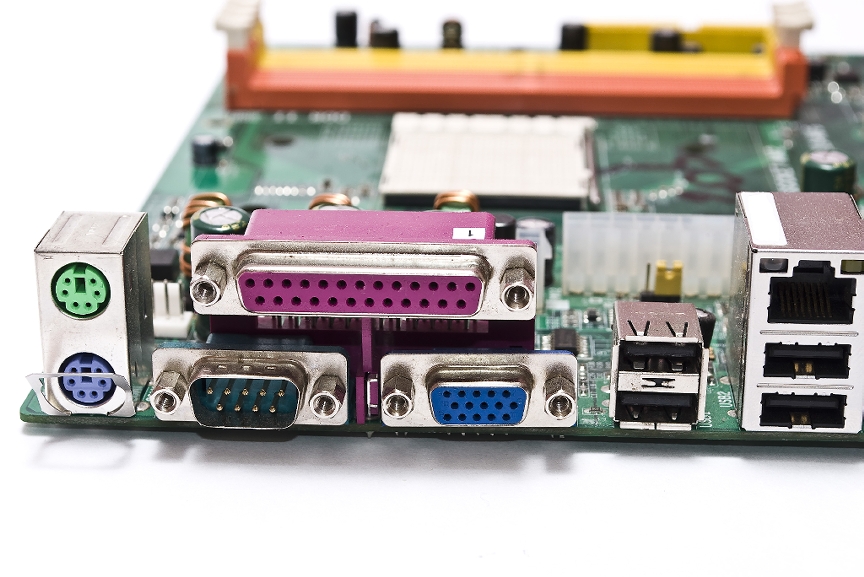

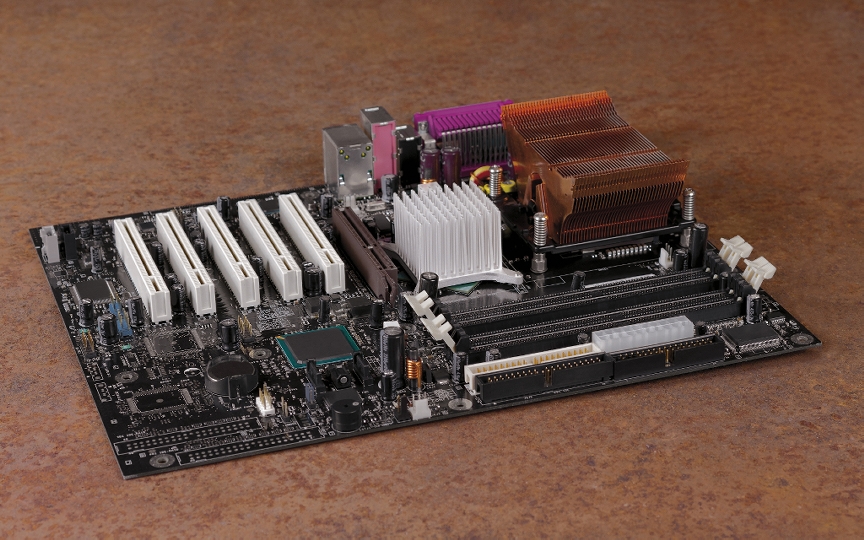

Over the past several decades, surface mounted technology (SMT) has grown in popularity and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Topics: assembly manufacturing, consumer electronics, smt production

Why You Should Look To SMT For Your Next Circuit Build

For most of the history of manufactured electronics, "through hole" printed circuit boards have been the standard. The idea has been effectively unchanged since the 50s, although there've been improvements in size and manufacturing quality. A through-hole circuit board needs holes drilled through it for connections and circuitry to pass through.

Topics: assembly manufacturing, consumer electronics, smt production

Who Comes Out On Top Between SMT vs. Through-Hole Mounting

As technology continues to evolve, we must work to find ways to keep up with it. Although through-hole mounting or technology was the predominant option for developing printed circuit boards (PCBs) for decades, today's consumer demands require electronics manufacturers to embrace new technologies as a means of developing compact yet highly dense boards. The most popular solution has been surface mount technology.

Topics: assembly manufacturing, consumer electronics, smt production

Topics: assembly manufacturing, consumer electronics, smt production

What Is the Difference Between Through Hole And Surface Mounted Technology

Over the past several decades, surface mounted technology (SMT) has grown in popularity and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Topics: smt production, smt manufacturing, surface mounted technology

Surface Mounted Technology Makes Manufacturing Processes Smooth

Although still a relatively newer concept, surface mounted technology (SMT) is quickly becoming the "go-to" method for mounting components to a printed circuit board (PCB). Are you familiar with SMT processes? Many electronics companies are comfortable with the tried-and-true through-hole mounting process, but SMT can make things a lot simpler and more efficient. To prove this point, here's a look at what surface mounted technology actually is, and when it can be used to make processes smoother for your business.

Topics: smt production, surface mount technology, surface mounted technology