Contract electronics manufacturing has finally grown up, and it's time more people knew about it!

Contract electronics manufacturing has finally grown up, and it's time more people knew about it!

For the past twenty years or more "assembly electronic services" have largely meant cheap overseas production, taking pre-made schematics and churning out whatever is in them. Companies employing such manufacturing partners usually had to do all the other leg work themselves, commissioning designs and prototypes and system software from other companies.

This made it very hard for all but the largest of firms deploying such methods to create products of the same quality that consumers demand, and frequently led to significant transportation issues, communication errors, and other unforeseen issues.

However, there's a new breed of assembly electronic services, ones who can deliver every service you need to launch a new product - and at affordable costs. If you're still using "fire and forget" offshore assembly services, it might just be time to think bigger.

5 Ways Modern Electronics Assembly Partners Make Better Products

1 - Design and revision services

Today, all it takes is having the idea for a product, and you can still see it happen. The best contract electronics partners have engineering experts on staff who can create products from scratch, or help revise and optimize existing designs to create the best possible final design.

They can also walk you through the design process, and help you understand the different production methods available, along with their pros and cons.

2 - Extensive testing

In the consumer market, especially, thorough testing is a necessity. People are very often rough on their electronics, and they have to be built with real-world usage in mind. Likewise, the onboard software has to be tested as well, to guarantee the product meets all the claims on the packaging.

A manufacturing partner with their own testing labs can also provide extensive predictive feedback on likely failure rates, allowing you to fine-tune your post sale expenditures.

3 - Software development

Software and hardware go hand-in-hand in modern electronics, and unless both are top-grade, a product is unlikely to succeed. By having in-house software development servic

es, today's top-grade manufacturers can personally guarantee a perfect match.

Otherwise, outsourcing software development means significant delays, or else unacceptable levels of guesswork on the part of the software team, who can't work off official hardware.

4 - Supply line oversight

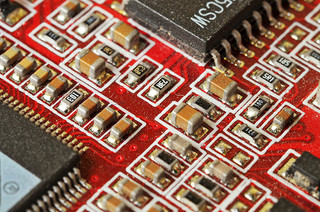

With modern per-component trac

king processes, such as barcodes or RFID tags, it's possible for manufacturers to oversee

every part being used on every PCB, to guarantee only legitimate parts are used in production. The problem of counterfeit components is a serious one in the manufacturing sector, and only this level of oversight can ensure an end product that's truly up-to-spec.

5 - Post-sale support

When we say "all-in-one" solution, we mean it. In the best cases, your manufacturing partner can handle post sale support and repair services, often significantly slashing post-sale costs compared to other solutions on the market.

Not only is your manufacturer going to be more familiar with the product than any outsourced call center, but they're going to have an inherent interest in ensuring your customers are happy with your products. More business for you means more busine

ss for them.

If it's time for a change in how you think about electronics assembly services, give ZenTech a call. We can take your next product to market, and beyond.