As a prime contractor to both the US Army (APG-ACC) and Navy (NSWC-DD), Zentech is very experienced operating in a task order environment on contract vehicles. Proper Task Order Execution is essential for accurate accountability and tracking of customer programs and schedules. Below are some best practices to ensure Task Order Execution success.

As a prime contractor to both the US Army (APG-ACC) and Navy (NSWC-DD), Zentech is very experienced operating in a task order environment on contract vehicles. Proper Task Order Execution is essential for accurate accountability and tracking of customer programs and schedules. Below are some best practices to ensure Task Order Execution success.

Establish one primary POC to communicate with customer.

For example, task order management processes can be managed by a Program Manager. The PM will organize, schedule, and begin monitoring all phases of work described in the task order proposal. The PM will also prepare progress reports, conduct progress meetings, communicate with the customer and ensure that all deliverables are shipped on time.

2. Maintain a robust Enterprise Resource Planning system (ERP) with an integrated Material Requirements Planning (MRP) module for ordering and tracking project material requirements. This provides real-time orders-in-process tracking and coordinated design change and deviations.

3. Daily manufacturing meetings.

These meetings are comprised of the Procurement, Receiving/Shipping/Kitting, and Manufacturing Operations Staff. These brief meetings are held to assure understanding of the day’s planned tasks, and to promote effective planning, problem resolution, and risk mitigation.

4. Weekly reviews with all departments. - Manufacturing, Program Managers, executive administration, engineering, and purchasing conduct weekly reviews to ensure successful contract completion and collaboratively resolve issues that have come up during the week before.

5. Meticulous Parts Ordering and Receiving Process.

The Purchasing Department orders all materials (components, hardware, PCBs, wire, sheet metal) listed on the BOM (Bill of Materials) for each job. When materials are received they go through incoming inspection according to a Counterfeit Parts Mitigation Procedure and part accuracy is verified against the customer BOM. Once correct, the parts are placed in a Job Kit box. Prior to its release to manufacturing, Quality Assurance (QA) audits all production kits for compliance to “machine ready” requirements, BOM completeness, and component integrity. Each job is serialized so that it can easily be tracked throughout the manufacturing process.

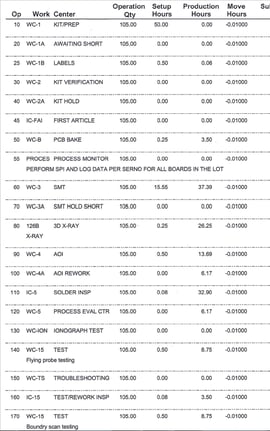

6. Create a Production Lot Traveler (PLT) and Assembly Instructions (AI).

The PLT lists the operations required to fabricate/assemble/inspect/test each item. The AI is the actual instructions used to assemble the product. These are both reviewed by the Production Manager and Quality Assurance and approved for use. The Production Manager assigns the job to assembly personnel and they review the the PLT and the AI. The item is then assembled in accordance with the PLT and AI and inspected by Quality Assurance at In-Process and Final Inspection.

All of these checks and balances ensure that a contract can be completed on time, on budget and with zero defects. Each step in the process allows for adjustments or corrections to occur real time, instead of discovering them at the end of the build or worse, when it's already arrived at the end user.

About Zentech:

Zentech Manufacturing, Inc. is a privately held, engineering-driven contract manufacturer specializing in the design and manufacture of highly-complex electronic and RF circuit cards and assemblies. The company is headquartered in its purpose-built facility located in Baltimore, MD, and in Fredericksburg, VA, and maintains several key certifications, including ISO 9001:2015, ITAR (US State Dept.) and AS9100 (aerospace). In addition, Zentech is a certified IPC Trusted Source supplier for Class 3 mission-critical electronics, and the company is IPC J-STD-001 Space Addendum QML certified and is now NIST 800-171 compliant. Zentech Fredericksburg operations is also a Mid-Atlantic leader in the fabrication of wire harnesses and over-molded cables for harsh environments.