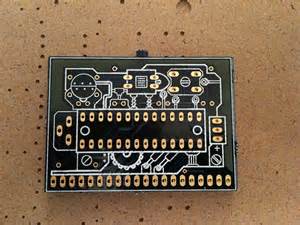

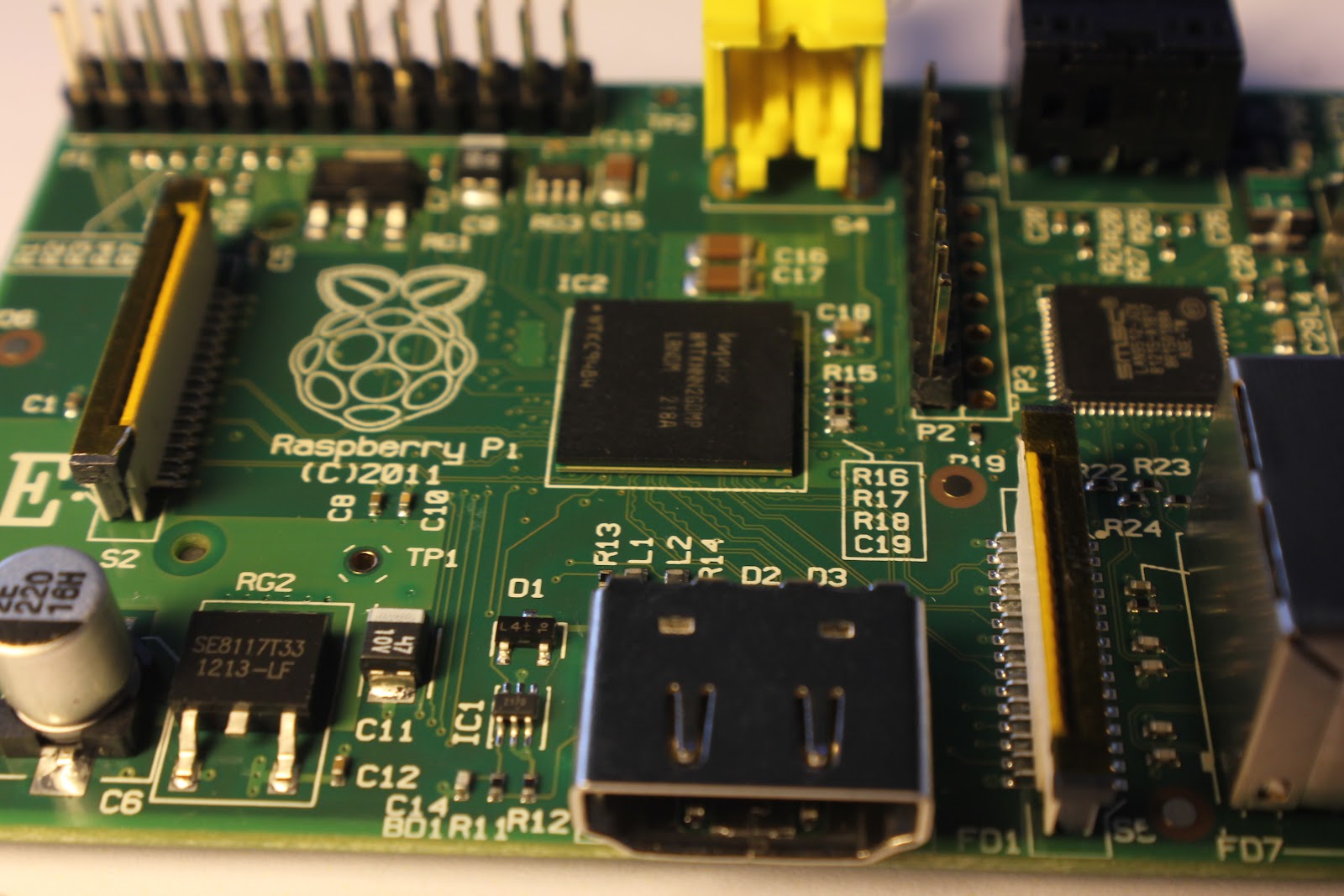

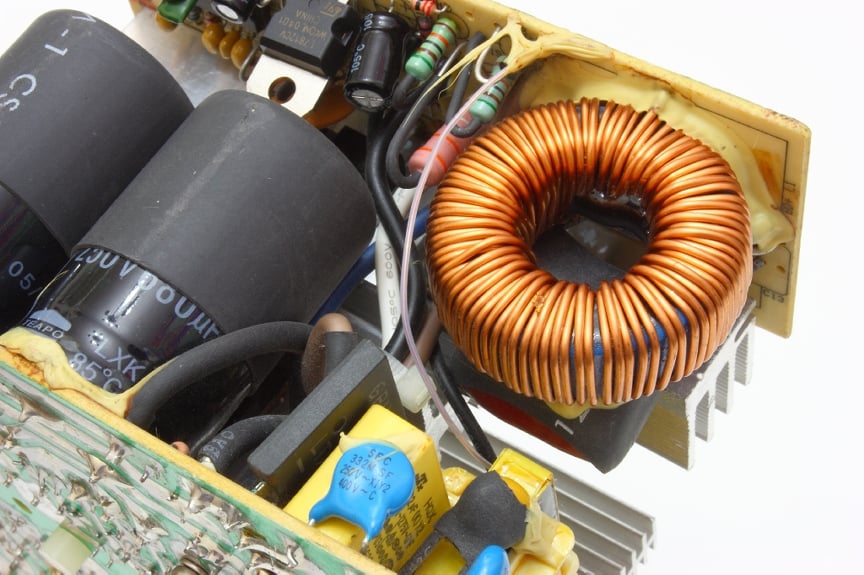

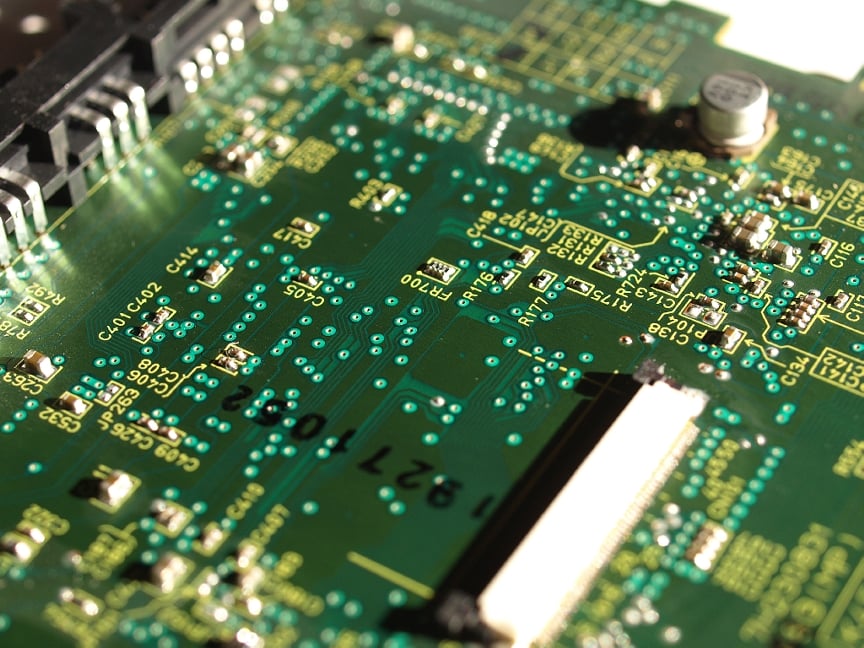

In any industry, it's extremely important that you're able to keep up with (if not surpass) the competition by offering the very best products and services. This is especially true in the electronic sector. With every passing moment, further advancements are being made in our technological capabilities and processes, which results in a consumer demand for increasingly complex yet affordable and user-friendly products. Of course, behind every great electronic device is an advanced, well put-together PC board.

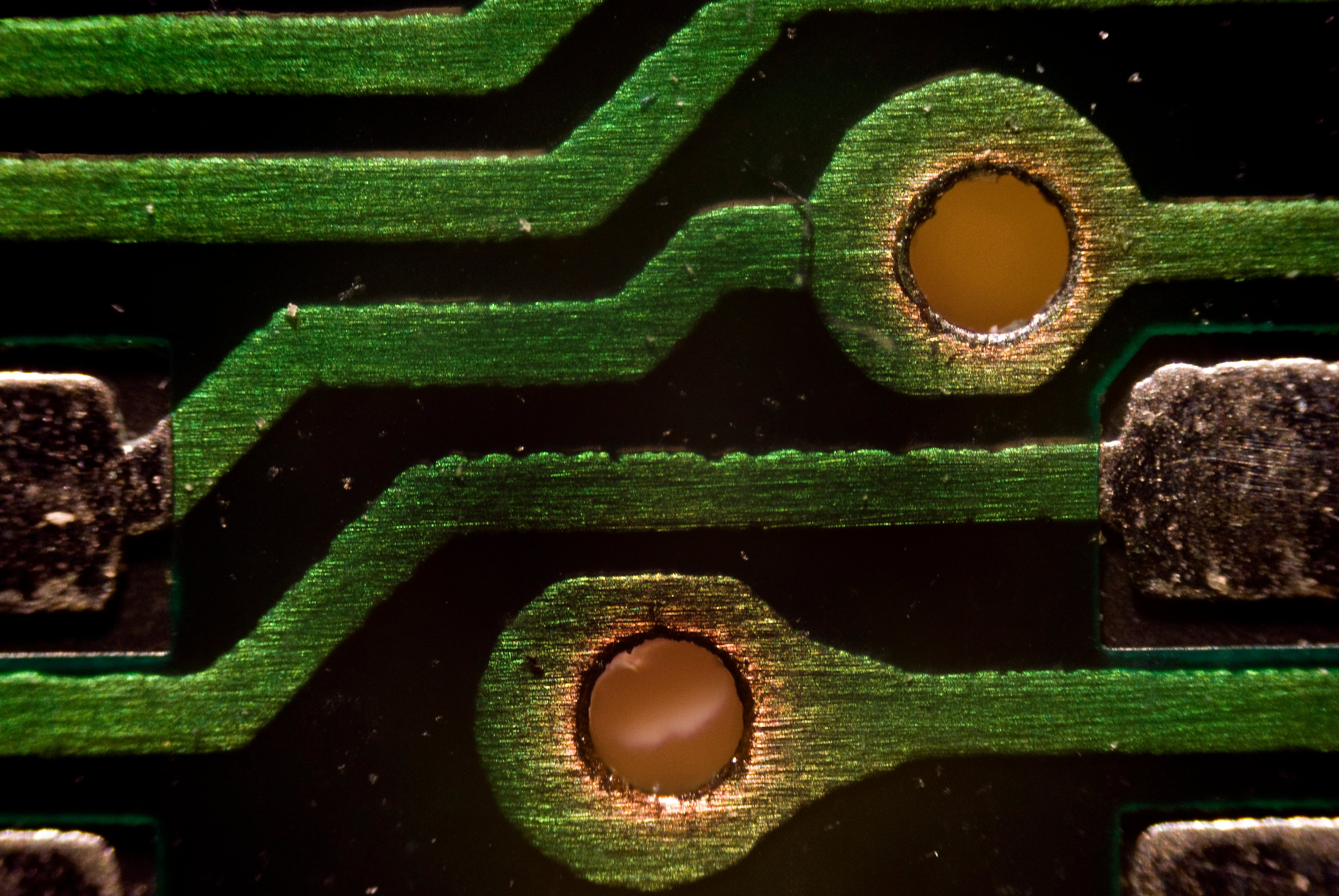

It's true! Although most users will never even take a glimpse at a PCB (let alone begin to understand how it works), these units are the backbone of our technology. As such, it's absolutely crucial that a lot of care goes into the manufacture and assembly process. But what is it that sets a superior PC board apart from a mediocre or low-quality board? Unless you know, you could end up partnering with a less-than-qualified contract manufacturing company. To eliminate any future stresses or headaches on your end, let's take a look at what actually goes into the assembly of the best PCBs.