Though most people may not realize it, the fact stands that manufacturing services and assembly solutions require some of the most skilled and careful employees in today's workforce. After all, designing and crafting precise electronics are extremely challenging processes. Ultimately, this is the reason that many electronics companies decide to seek out a manufacturer who offers design and assembly solutions. But why should you outsource the manufacture of your products instead of handling it in-house? Here is a look at three ways that professional assembly solutions can solve your problems, and how to get the most out of your investment.

Assembly Solutions: How They Solve Your Problems

Topics: assembly electronics solution, assembly solutions, assembly manufacturer, assembly electronic

4 Ways A Contract Manufacturer Can Provide Solutions For You

No one likes to hear about a problem, but everyone is ready for a good solution! Unfortunately, finding an efficient and effective method for resolving any issues that your busies may be having can be a bit more challenging than it initially sounds - especially if your resources are somewhat limited. The good news for SMBs in the electronics industry is that a contract manufacturing company can actually help to stretch your resources, and empower your company by providing you with affordable and workable solutions that can improve your customer satisfaction rates and boost your sales revenue.

Let's explore just a few of the ways that a contract manufacturer can help to provide solutions to your problems and drive your cares away.

Topics: assembly electronics solution, assembly solutions, assembly manufacturer, assembly electronic

5 Characteristics Of A Great Contract Manufacturer

As a small to mid-sized electronics company, you may find yourself struggling, from time to time, to keep up with the large brands and businesses. While these "big fish" game players may be able to afford to employ a large staff of skilled designers and engineers, and stay on top of the latest and greatest assembly machinery, you may not have the same resources available to you. This is not an uncommon problem. To find success, many SMBs choose to contract the production of their PC boards out to a third-party manufacturer.

Topics: assembly solutions, boards, pc boards

Domestic Assembly Solutions Go Beyond Mere PCB Assembly!

Perhaps it's due to the last decades' rush for outsourcing, but a lot of people think that an electronics assembly partner is nothing but a hired plant for stamping out parts. While this may be true for some cut-rate overseas plants, the truth is that domestic assembly solutions can be your all-in-one source for bringing new products to market.

Topics: assembly manufacturing, assembly solutions, assembly electronic

Why Look Abroad For Assembly Solutions? Reshoring Is Growing! and it brings better hardware!

For awhile, it looked like the entire manufacturing industry was going to move abroad for their operations. The promise of super-cheap assembly solutions in China or Vietnam or other low-cost countries lured plenty of businesses overseas. When a company could get manufacturing done for one-fourth – or less – of domestic services, it made a compelling financial argument.

Topics: pcb assembly, assembly solutions, American based product assembly

Who Do You Trust For Your Electronic Assembly Needs?

For small to mid-sized electronic companies, making the decision to outsource their assembly electronic processes is a bit of a no-brainer. The cost to work with a third-party professional is often much less than it would be to hire a full team of skilled laborers, and the burden of purchasing and maintaining expensive equipment is removed from your shoulders. When you've got an excellent outsource vendor on your team, you can remain competitive with larger-scale industries and grow your business.

Topics: Contract Electronic Assembly, contact manufacturers, assembly solutions

In case you haven't already noticed, the electronics market is getting more and more competitive with every passing year. It really doesn't matter what industry you're working in, either. Whether you're developing high-tech aerospace technology or complex communications devices, you've got to contend with an array of similar products and find a way to stand out. This requires you to be the absolute best in everything from design to marketing and everything in-between. The problem for smaller companies like your own is that you may not have the manpower or resources available to give equal attention to both the creative development side of production, and the actual process of device assembly. If this sounds familiar, contract manufacturers are the solution.

Topics: Contract Electronic Assembly, contact manufacturers, assembly solutions

Conquer Production Problems With Great Assembly Solutions

Our world has become one that is extremely reliant upon electronics. Everyone, including the government, the healthcare sector, industrial corporations and even individual consumers are all in need of electronics products that are not only high-quality but also affordable. Although

this is great news for electronics companies, it can also create manufacturing challenges.

Topics: assembly electronics solution, assembly solutions, quality of services

Why Should Your Company Use An Electronics Manufacturing Service?

Whether you're struggling to efficiently produce your electronic devices in-house or are just starting your business and are seeking an electronics manufacturing service, your primary goal is to find a partner that will help you to generate high-quality products in a way that is fast and cost-effective. You know that this is important, but if you've got a business partner or superior who is questioning the need to contract with a third-party manufacturer, you must be able to justify the investment. In order to get what you need, here are the top five reasons for working with an American electronics manufacturing service.

1. Design Products with Fewer Bumps in the Road

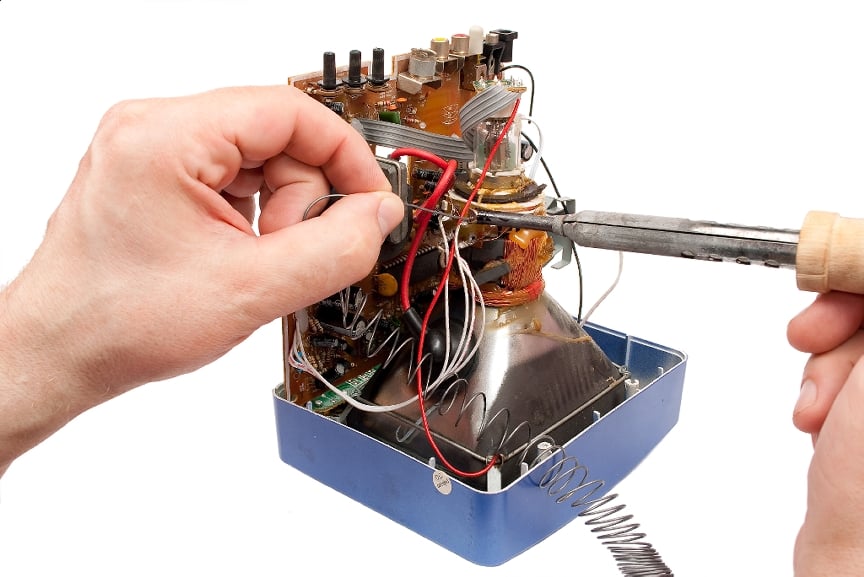

Creating small, complex electronics can be extremely challenging, and your team of engineers my struggle from time to time with problems that take them all the way back to square one of the design process. Unfortunately, when your staff have spent too much time examining a project, it may become difficult for them to see a solution that is right under their noses. Because of this, it's wise to bring in a fresh set of eyes, who may be able to solve the problem more quickly. In this way, your business is able to keep moving forward, instead of getting stuck on bumps in the road or required to scratch a design completely and begin again. Ultimately, this can save a significant amount of man hours, money, and stress.

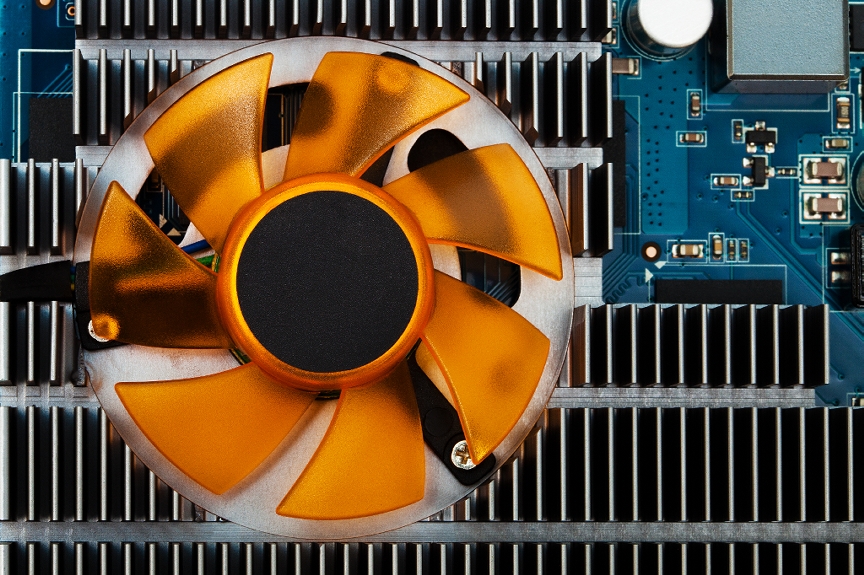

2. Make Use of High Quality Machinery and Parts

Sure, your company may use good machinery in the creation of your products, but in order to stay competitive with other businesses, you've got to have the best. By working with an electronics manufacturing service, you can take advantage of the latest and greatest technologies without having to purchase it yourself. Assembly solutions, for example, can streamline the process of manipulating tiny parts and pieces, making the process faster and more accurate from start to finish. And by choosing to work with an American manufacturer, you can rest assured that all of the parts used in the construction of your devices will be of the highest quality. In fact, your service may actually have connections to suppliers who can offer better parts for less dough.

3. Produce Fewer Faulty Devices

When you're able to produce your devices with the highest quality parts and machinery, you won't be throwing out entire batches of electronics as a result of errors. With fewer faulty devices on your hands, you'll be able to increase your profit margins and get the most bang for your buck.

4. Get your Products to the Masses Faster

Working with a professional electronics manufacturing service means that, from start to finish, your products will be designed, produced, tested, and shipped to end-users far faster than ever before. And the quicker you are able to get your devices to the masses, the faster you can start bringing in sales revenue and profiting. But faster doesn't mean reduced quality. Each of your devices will still be held to the highest standard so that you aren't hit with consumer complaints, warranty claims, or other related issues.

5. Scale Back on Your Spending

When you find a reputable electronics manufacturing service, you can spend less on product repairs. Broken or faulty equipment can be sent directly to your manufacturer for fast troubleshooting and fix-it jobs so that you don't have to lose money on warranty replacements. Additionally, you'll spend less time and money on shipping the faulty device to the manufacturer, waiting for it to be repaired, and having it shipped back to you before sending it to the customer. And after developing as solid relationship with your electronics manufacturing service, you may find that you begin to save money, as they are able to offer you discounted services for your loyalty.

Find out firsthand how an electronics manufacturing service could benefit your business. Are you ready to get started?

Topics: assembly solutions, electronics manufacturing service, third-party manufacturer

Assembly Solutions Create Efficient Processes

When you find your "groove" in running your business, you'll be hard pressed to try and change that for something else. The steps to find that efficiency will also mean doing some research, shopping around for the right fit with outsourced companies and making sure all of your work is getting done. The same can be said about efficient processes when it comes to assembling all of your products that are outsourced to an assembly company.

Topics: assembly electronics solution, assembly solutions, quality of services