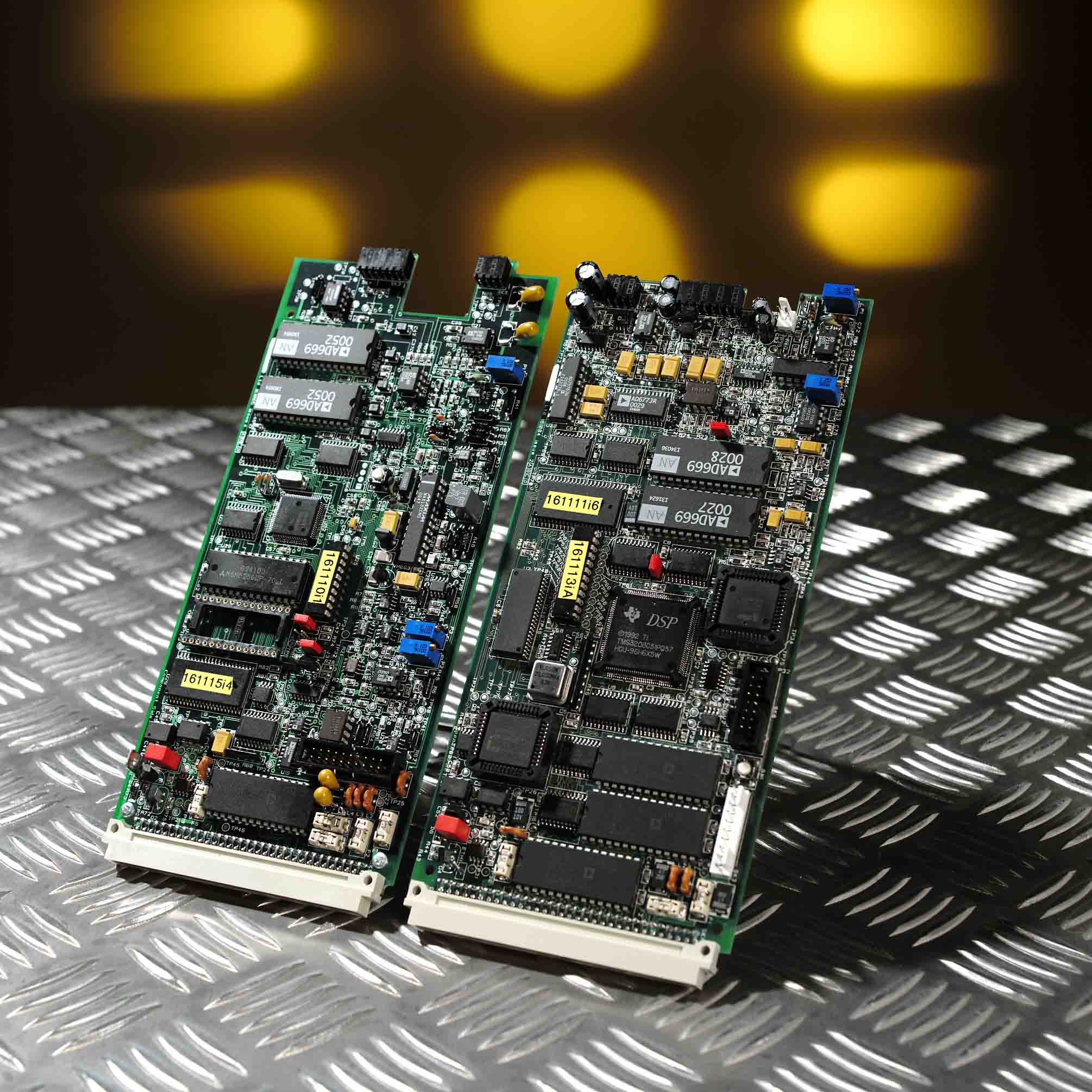

Avnet recently released the Q3 2019 Market Conditions Report for the electronics industry.

Topics: SMT Assembly, Maryland PCB assembly, electronics manufacturer, electronics supply chain

Exceptional program management is the key to a successful relationship between customer and Contract Manufacturer.

Zentech is qualified to ensure sustained high-quality program performance due to our experience and knowledge of planning, change management, quality management, staffing, and reporting requirements. We have an exceptional track record of applying recognized best practices that exceed our clients’ expectations.

Zentech's approach to program management is guided by our established project management process, as well as the PMI and PMBOK disciplines. The knowledge, skills, and abilities of our management team enable us to successfully oversee and track the technical performance of each program activity, including cost and schedule, in order to avoid delays and quickly resolve issues.

Topics: SMT Assembly, Maryland PCB assembly, electronics manufacturer, electronics supply chain

The Trump administration is praising IPC – Association Connecting Electronics Industries® and several of its member companies for their efforts to expand the skilled workforce.

On July 25, an IPC group took part in a White House event marking the first anniversary of President Trump’s Executive Order to develop a national strategy to expand the skilled workforce. The event took stock of the progress made under that executive order and the related Pledge to America’s Workers, which called on private sector companies to step up their workforce upskilling efforts.

IPC responded to the President’s challenge by reviewing its education programs and seeking ways to grow and innovate. As a result, IPC last October joined in the pledge and made a commitment to create 1 million new skilled workforce opportunities over five years. Since then, IPC has made unprecedented, multi-million-dollar investments in its already-extensive educational programs, including trainings and valuable certifications for adult workers; new university chapters and electronics courses; new curricula and outreach aimed at students in middle and high school; and establishing the IPC Education Foundation, which prepares students for rewarding careers by supplying learning opportunities focused on electronics manufacturing and improving the perception of manufacturing as a stable and well-paid sector.

Topics: SMT Assembly, Maryland PCB assembly, electronics manufacturer, electronics supply chain

Vote for John Vaughan (Zentech) for SMTA Board

Zentech is proud to announce that our very own John Vaughan is a nominee for the SMTA Board of Directors!

Four SMTA director positions will be filled for the term 2019 – 2022. We would like to encourage you to review the candidates now!

Voting ends soon and your participation will help shape the future of the SMTA and the electronics industry.

Topics: SMT Assembly, Maryland PCB assembly, electronics manufacturer, electronics supply chain

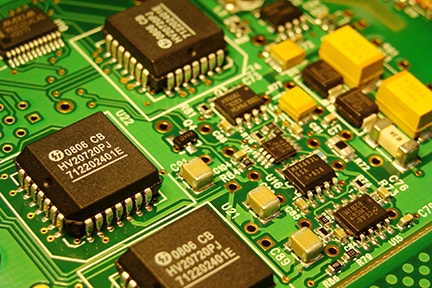

Circuit boards manufactured with Surface Mounting Technologies have revolutionized electronics manufacturing, thanks to their ease of construction and the much higher component density they make possible. SMT construction allows for devices which are smaller, more feature-packed, and (very often) cheaper to produce.

Topics: SMT Assembly, smt manufacturing

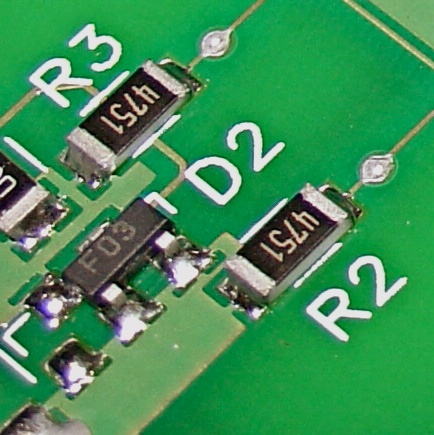

What Is The Difference Between SMT and Through Hole Technology?

Surface mounted technology (SMT) has grown in popularity over the past few years and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Topics: SMT Assembly, smt manufacturing, through hole mounting

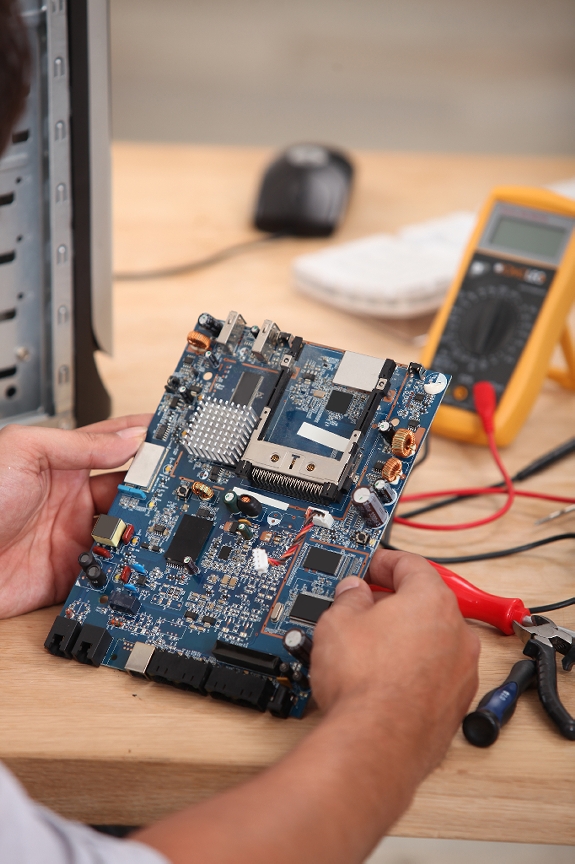

SMT Production: Know The Basics Before You Start

There are different approaches to mounting components onto a printed circuit board with each method having its own strengths and weaknesses. This brings up the need of understanding what a given circuit is expected to do hence going for an approach that will bring the best in terms or performance and durability out your circuit.

Topics: surface mount technology, SMT Assembly, smt manufacturing