There are countless Electronic engineering, manufacturing companies out there and this makes it difficult to find a reputable company that can provide you with a satiating job of electronic assembly services. Going through all the companies to find the one that will deliver the results that you want can be time consuming, and not to mention, depleting your budget slowly.

Matthew Turpin

Recent Posts

How to Employ The Best Assembly Electronic Engineering Company

Topics: assembly electronics, assembly electronics solution, assembly manufacturing companies

EMS Electronics Create The Perfect Way To Bring Your Product To Market

With the explosion of Internet technologies and global shipping, there's a market for devices today that's unmatched at any time in history. Global demand for electronics is skyrocketing, and there's plenty of opportunity for a company to grab a piece of the market.

Topics: ems electronics, Contract Electronic Manufacturers, Electronic Manufacturing Solutions

Thinking About Contracting With An Offshore Electronic Manufacturing Company? Why You Should Reconsider...

Topics: electronic manufacturing company, American based product assembly, american electronics design services

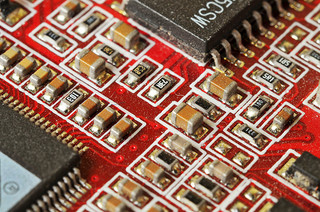

We all know what a stencil is, in the traditional sense. Children often make use of plastic stencil sheets in order to practice drawing shapes, while sign makers and other professionals are able to utilize them to create perfect letters. Here in the world of designing and manufacturing PCBs, though, we rely on laser cut SMT stencils. Although not too far off from the regularly recognized units, these laser cut SMT stencils are much more complex and simplify the process of PCB assembly by making it easier to apply solder paste to the board. This post will cover everything that you need to know about laser cut SMT stencils.

Uses

Throughout the electronics manufacturing process, a stencil may need to be used for a couple of purposes. First and foremost, stencils are a true life-saver when producing a board that relies on surface mount technology (SMT). Another instance when stencils are useful involves the use of automated component placement equipment (with the exception of hand-loaded prototypes. Why? Because it acts as an alternative to the requirement of hand soldering every single component.

Topics: smt production, surface mount technology, assembly pcb

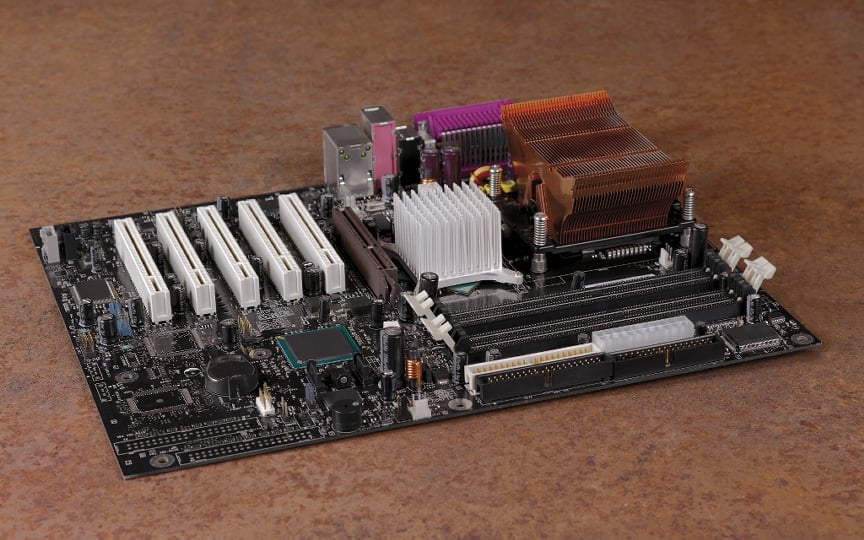

Through Hole And Surface Mounted Technology - What is the Difference

Over the past several decades, surface mounted technology (SMT) has grown in popularity and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Topics: assembly manufacturing, consumer electronics, smt production

Why You Should Look To SMT For Your Next Circuit Build

For most of the history of manufactured electronics, "through hole" printed circuit boards have been the standard. The idea has been effectively unchanged since the 50s, although there've been improvements in size and manufacturing quality. A through-hole circuit board needs holes drilled through it for connections and circuitry to pass through.

Topics: assembly manufacturing, consumer electronics, smt production

How Contract Manufacturers Help You Stand Out

From time to time, we all need a little bit of help. As a business owner, though, you may tend to pride yourself on your independence, and have a strong desire to keep all of your processes in-house. But what if soliciting design, assembly, testing, and fulfillment services could actually help you to grow your company an enable to you bring in more cash? That would probably grab your interest, and it has, indeed, peaked the curiosity of other small to midsize electronics businesses. A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 6 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

1. Knowledge & Experience

Topics: assembly manufacturing, electronics contract manufacturing, assembly manufacturing firm

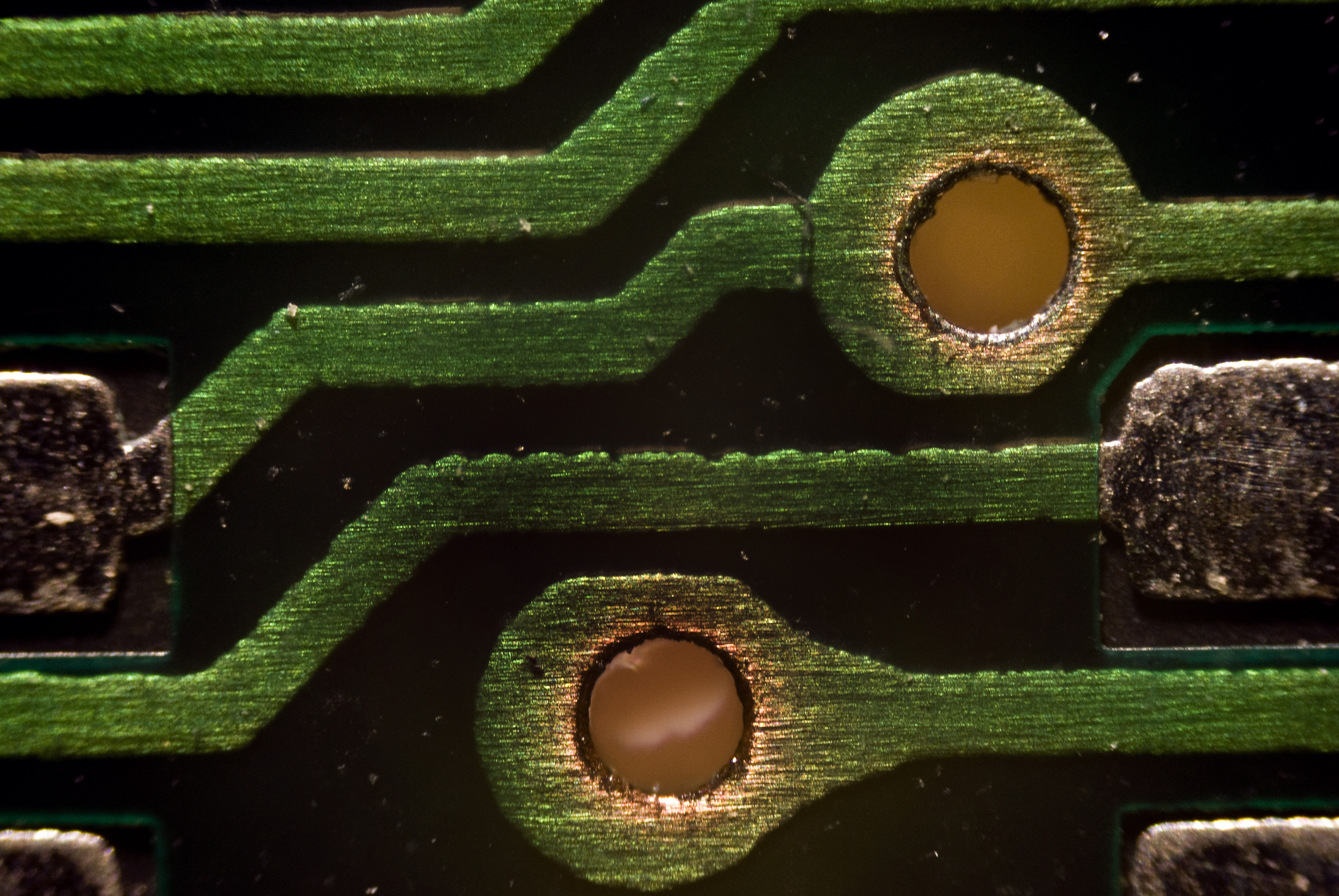

PCB Assembly & Manufacturing - You Know the Drill

It may seem like ancient history, but there was a time not so-very long ago when printed circuit boards were drilled with a simple drill press. An operator would repeat the process of manually moving the panel to the exact X and Y coordinates before pulling a lever and drilling an individual hole. Fast-forward to today and consider the fact that our modern PCBs often require more than 10,000 drill hits in all different sizes. Just imagine how long it would take an operator to complete one measly project using the old methods of drilling! Fortunately, the process has been simplified significantly throughout the years. Let's take a look at how our methods have evolved, and what drilling a PCB entails today.

Topics: assembly manufacturing, inventory management, contract electronics manufacturing

Improving Your Business Model Through Outsourcing Manufacturing Services

In an increasingly globalized economy, it's growing more and more important for electronics companies to have the ability to reach out to new consumers by increasing capacity. At the same time, however, these businesses can't afford to add capital investment costs or lower the quality of their devices. Outsourcing companies exist primarily to fulfill this unique need. Through a strong partnership with a quality contract manufacturer, businesses can scale up, remove the more tedious and time-consuming tasks from their repertoire and put their focus on core competencies. It's because of this that so many OEMs are looking to outside help in order to prove their business models.

Why do companies hire contract manufacturers?

Topics: manufacturing services, American based product assembly, american electronics design services

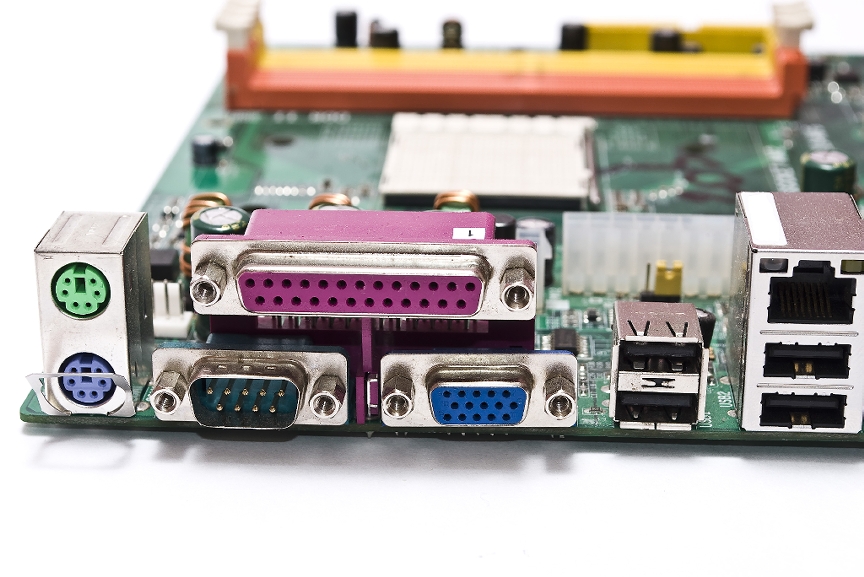

Every high-tech electronic device began with a solid design. Not only does the design process allow engineers to flesh out their many options, but the completed schematic acts as the blueprint for the manufacture of a device, and provides valuable insight for those who must troubleshoot or repair a unit down the road. Because of this, it's extremely important that your board designs are thorough and easy for others in the electronic engineering field to understand and make sense of - especially in cases where you plan to outsource the assembly and manufacture process. To ensure that your project goes off without a hitch, we've written this post to explore the importance of proper electronics board design and how to guarantee that the job is done right.

The Value of Excellence in Board Design

Topics: engineering design services, design services, designing processes