Contract electronics manufacturing has finally grown up, and it's time more people knew about it!

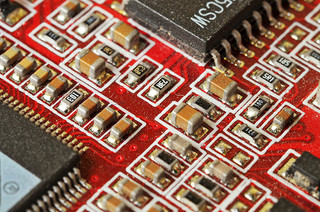

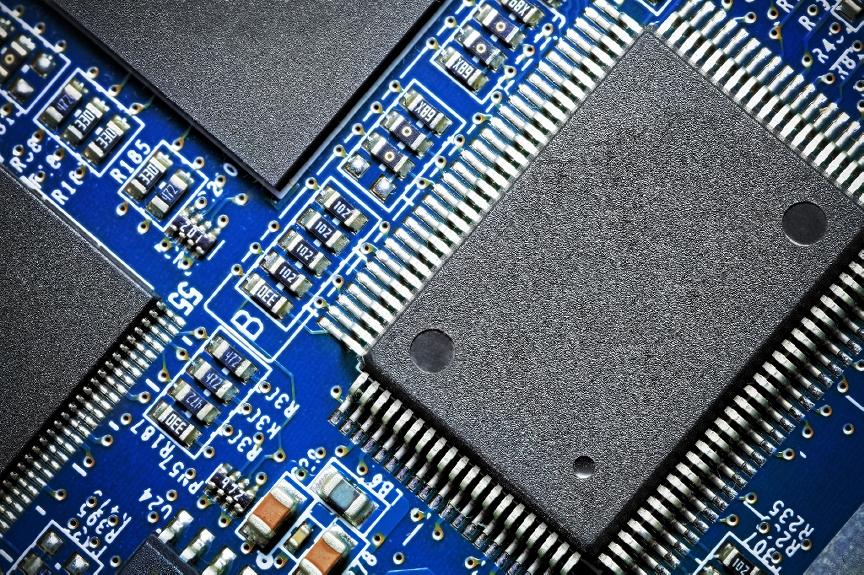

For the past twenty years or more "assembly electronic services" have largely meant cheap overseas production, taking pre-made schematics and churning out whatever is in them. Companies employing such manufacturing partners usually had to do all the other leg work themselves, commissioning designs and prototypes and system software from other companies.

This made it very hard for all but the largest of firms deploying such methods to create products of the same quality that consumers demand, and frequently led to significant transportation issues, communication errors, and other unforeseen issues.