If you haven't heard, the electronics manufacturing market is shifting rapidly! In response to the cut-rates being offered in developing nations, domestic facilities are now adding services you simply cannot get overseas. These can be extremely cost-effective, and add significant value to local manufacturing choices.

Topics: assembly manufacturing, contract manufacturing company, PCB Repair Services

Electronics Manufacturers With PCB Repair Services Bring Great Value

Are you still using a "what you see is what you get" electronics manufacturer, who do nothing but assembly? If so, you could be losing a lot money on one of the most costly aspects of electronics retail - post-sale support.

Topics: PCB Repair Services, pc assembly, electronics manufacturer

Contract Manufacturers Play a Role Throughout the Production Cycle

If you think that electronics contract manufacturers can do little more for your business than assemble your PC boards, think again. Many smaller scale electronics companies choose to work with a third party manufacturer because of their ability to remain involved throughout the entire production cycle. Regardless of where you are at in designing or manufacturing your products, you would be surprised by the level of assistance a contract vendor can offer. From start to finish, you can take advantage of just as much help as you require. Take a few moments to consider all that contract manufacturers can do for you; you'll wonder why you waited so long to work with one.

Topics: contact manufacturers, pc board assembly, PCB Repair Services

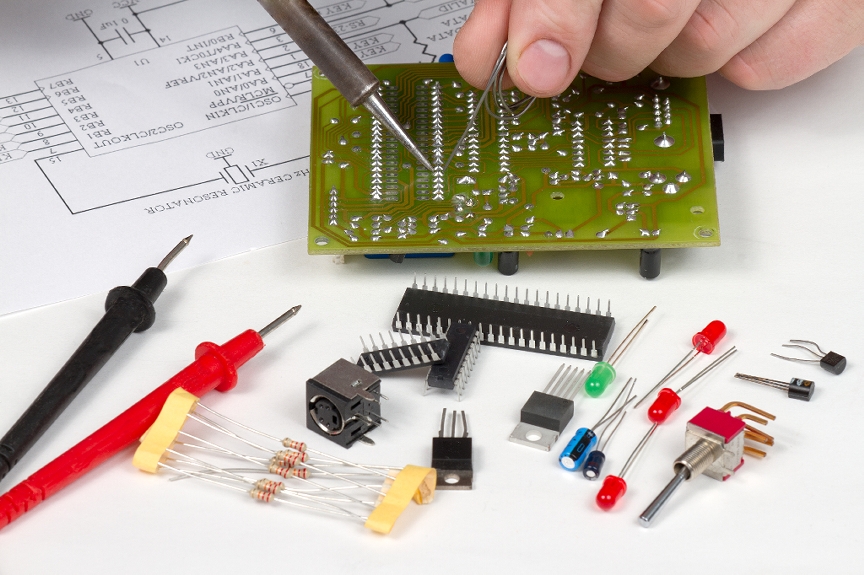

PCB Repair Services Make Old Boards Brand New

Even the best electronics companies aren't free from the possibility of a defect or fault developing within their products. Although major problems may arise from time to time, though, it seems wasteful to completely scrap a circuit board when only one component is causing the fault. Unfortunately, many smaller businesses do not have the time or the resources available to troubleshoot for the problem and make the necessary corrections. Professional PCB repair services can help by shouldering this burden for you. By taking the time to consider the issues that a contract repair service can provide and how it can work to your benefit, you could significantly improve your company's efficiency and effectiveness.

Topics: electronics design services, PCB Repair Services, PCB design services

When To Employ A PCB Design And Manufacture Company

Although your electronics business has been doing well, you may be feeling that it's time to take things to the next level and start growing. Unfortunately, trying to grow too quickly, without the necessary assistance and resources, can create serious problems. It is because of this that many small and medium sized companies choose to contract with PCB design and manufacture services for help in achieving their objectives. But is working with an outsource operation right for you? Here are six examples of instances in which you should think about hiring a contract manufacturer.

1. You need to streamline your products

Are your current products as efficient as they could be? Your in-house engineers may be knowledgeable, but if no outsiders have taken a look at your plans in the recent past, they may be overlooking factors that could make your devices even better than they are right now. If you feel that your business could benefit from cutting down the parts and materials necessary to manufacture your electronics, you may want to contract with a reliable PCB design and manufacture company for some assistance. Upon reviewing your schematics and existing PC boards, your partner company may be able to point out ways in which you could improve your product's functionality while streamlining its basic design, thereby saving you time and money.

2. You are struggling with design flaws

From time to time, we all get stuck on a problem. If you and your team are struggling to either pinpoint the root of a fault, or are unable to come up with a workable solution, it's time to seek help. By recruiting industry experts, you'll have the privilege of viewing the issue from a whole new perspective so that you can resolve them faster and get your perfected products out to your clients.

3. Your business is lacking in resources

Smaller electronics companies may be at a bit of a disadvantage as compared to their large scale competitors. Because the "little guys" have fewer financial and labor resources, it can be difficult to keep up with the ever-changing market and advancements to technology. If your company isn't able to employ the manpower necessary to create and produce PC boards, or if you don't have the ability to maintain expensive assembly equipment, you could benefit from hiring a PCB design and manufacture service. By contracting with a third party, you can take advantage of their resources without committing to permanent laborers or equipment.

4. You need to quickly produce a prototype

In many cases, our brains work faster than we can keep up with them. If you've got great ideas for a new product and need to demonstrate its abilities to your clients quickly, you may need a professional PCB design and manufacture agency to help you get your prototype developed and functioning properly. Through careful planning and testing, you can rest assured that your prototype will impress your audience so that you can generate future business.

5. Your production orders have increased

Has your business bitten off a bit more than it could actually chew? If you're struggling to keep up with the demands of your customers, a contract manufacturer can help you to automate the assembly process so that you can produce your PC boards and other devices faster, without sacrificing quality or precision.

6. You would like to reduce warranty replacement costs

How do you handle defective or faulty products? If your current solution is to simply ship off a replacement unit to your customers, you could be losing a lot of money. A PCB design and manufacture company that offers a customer repair and return depot will be able to scale back these expenses by taking the time to troubleshoot the device, correct the issue, and get it back to the client in no time.

Could you benefit from working with a PCB design and manufacture service?

Topics: engineering design services, PCB Design And Manufacture, PCB Repair Services

PCB Repair Services, It's More Affordable Than You'd Think

Topics: electronic design and manufacture, pcb board repair, PCB Repair Services