Sometimes, it just makes sense to keep your business under one roof.

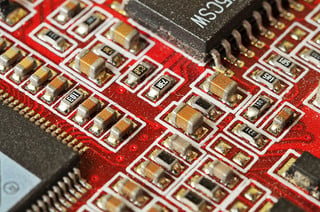

Demand is higher for electronics today than ever before, and at the same time, electronics manufacturing requires ever-greater levels of skill and precision to deliver top-quality products. Older methods of outsourcing different aspects of production are having trouble keeping up with this, as the layers of sub-contractors often cannot coordinate sufficiently well to produce a truly high-quality end product.