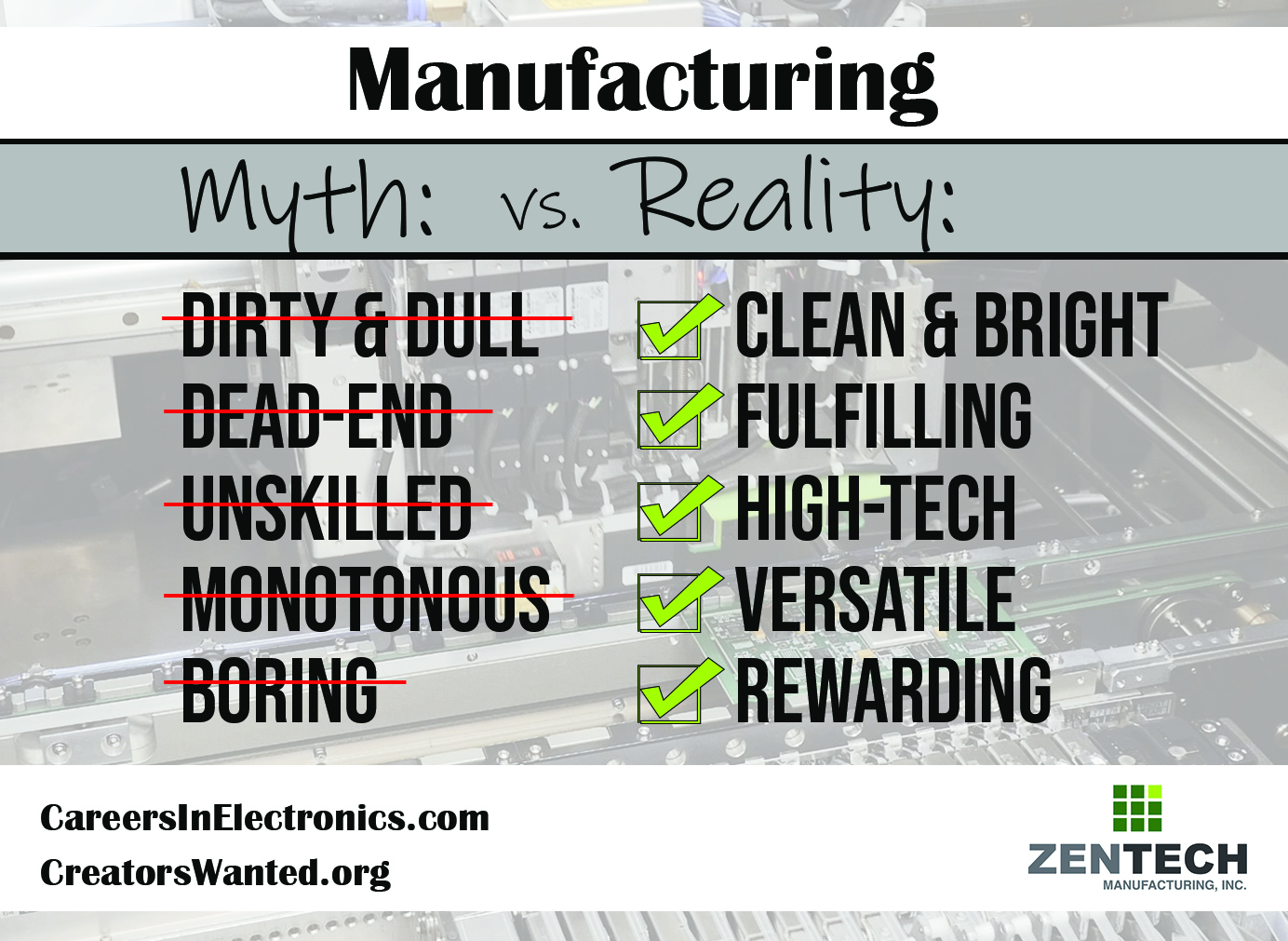

This blog series intends to shatter some "manufacturing myths". Sometimes there is a perception of manufacturing being dirty, dead-end, unskilled, monotonous and boring.The reality is, it's bright, clean, fulfilling, hi-tech, versatile and rewarding!

I had the privilege of interviewing some Zentech employees - a way of humanizing the manufacturing industry to demonstrate why you may want to consider a manufacturing career.

Melissa - Hand Soldering, Zentech Dallas

Stephanie: Have you always done this type of work?

Melissa: I’ve always done this. I started hand soldering in 1988 and this is the 3rd company I’ve worked for. I’ve had long tenures at companies.

Stephanie: Did you go to special schooling for hand soldering, or did you learn on the job?

Melissa: On the job. Though they sent me to IPC training. But from then on, I learned everything on the job.

Stephanie: So, what made you decide to take this route?

It just happened to fall in my lap. I was in college, and I had 2 brothers here in Dallas and one of my older brothers asked me to come and visit and get a summer job. I’m from Mississippi. I came to get a summer job and I never went back. I had friends who worked at a local electronics manufacturing company. They suggested I fill out an application. I’ve been in the industry ever since.

Stephanie: Why do you like your job?

Melissa: You know, I do a lot of re-work here. So, I think when I receive something that is broken, and I get to fix it – it feels like I really accomplished something.

Stephanie: And you have something tangible that you can say, “I fixed this.”

Melissa: Exactly. It goes back to the customer, and it works. That makes me feel good. I like fixing things.

Stephanie: A lot of the younger generation isn’t interested in manufacturing. Do you have an opinion on why or what you would tell them?

Melissa: The thing about it – the younger generation, they have more technology at their fingertips, it’s all just “there”. When I started, it was all new and so I recognized it – oh so this goes in a remote, or a radio.