Have you been thinking about hiring a third party manufacturing company to assist you with the design or assembly of your electronics? If so, it is very important that you understand what to look for in a quality and long-lasting business partnership. But with so many options, how can you even know where to begin? In order to help you narrow down your options and make the best decision for your operation, here's a look at the four types of electronic contract manufacturers that you should be looking to hire.

1. PCB Assembly Manufacturers

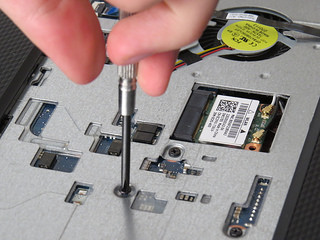

Technology is continuously evolving, and as it does, it is shrinking. Consumers today are demanding electronic devices that, while more complex and functional, are also extremely lightweight and compact. In order for these systems to operate properly and efficiently, printed circuit boards (PCBs) must also become smaller, while being able to support increasingly complicated electrical connections and components. Designing and assembling these tiny PCBs can be challenging, time-consuming, and very costly to electronics operations with finite resources. In order for you to fulfill customer orders, stay competitive, and grow your business, you may want to consider working with professional electronic contract manufacturers. Skilled and capable outsource partners can hep you to overcome and obstacles that your team is meeting and can provide high-tech machinery that will ensure faster, more precise PCB assembly.

2. Systems Assembly Manufacturers

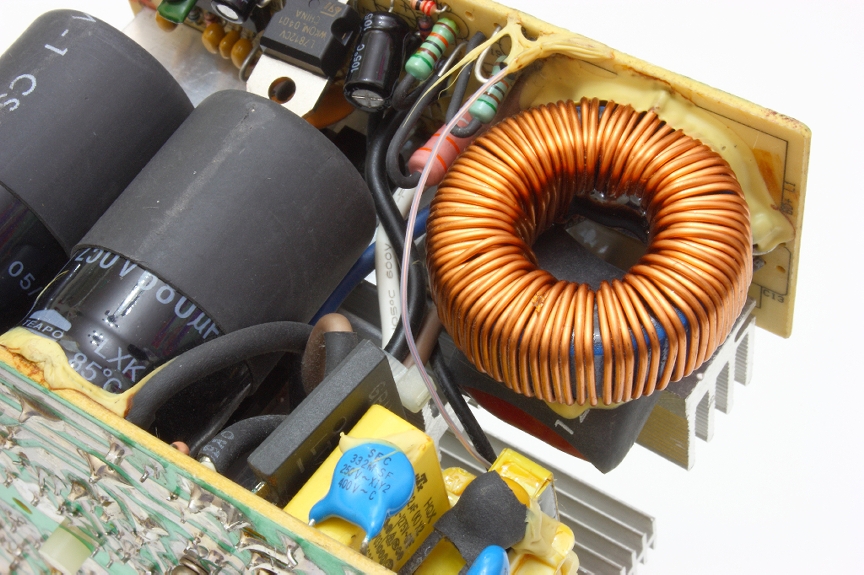

If your business is struggling with systems assembly, electronic contract manufacturers may be able to help. By choosing an experienced business partner that is familiar with all of the demands of system assembly, you can be the recipient of customized solutions that will help to manage your supply chain requirements. Regardless of what level of assistance you require, you can find relief and higher levels of success with the right contract manufacturer. Truly reputable third party companies will be capable of helping you with configure/build to order design schematics, assembly at the chassis, cage, or rack levels, custom cabling, board and system testing, and documentation management so that you can operate more efficiently.

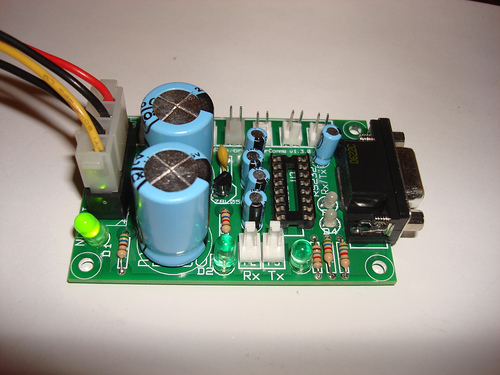

3. Design and Build Manufacturers

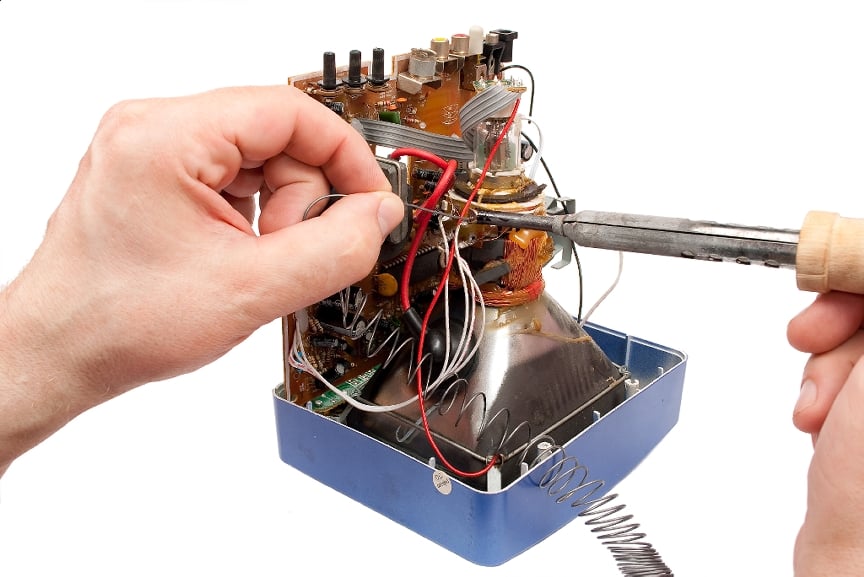

There are many electronic contract manufacturers that only offer assembly services. Although this can help you to improve the speed of actually producing a fully designed product, it will not help you to improve the efficiency of your electronics. A design and build service may be able to pinpoint areas of your basic schematics that could be improved, thus saving you money on parts, or enabling you to create products that are easier for end-users to manipulate or that function more smoothly. Throughout the assembly and manufacturing process, your partner will be testing your products for operability and for problem areas that could be fixed. In this way, your business and your products will always be getting better.

4. American Based Manufacturers

At first glance, the electronic contract manufacturers that work offshore may seem like the more economical choice for a business partnership, but you should keep in mind that you get what you pay for. Although many foreign companies offer cheaper services, they also tend to cut corners and use bootlegged parts and system components during product assembly. And because cheap, unskilled labor is utilized throughout production, your devices may end up falling short of the expectations of yourself and your customers. To avoid these problems, it is in your best interest to work with American based companies that follow national manufacturing and assembly standards, and that utilize only high quality parts.

The right electronic contract manufacturers can be a tremendous asset to your business. By looking for these four types of manufacturers, you will enjoy more efficient daily operations, and will be able to provide better products to your customers.

4 Types Of Electronics Contract Manufacturers To Hire

Topics: pcb assembly, Electronic Contract Manufacturers, contract manufactuerers

The Road Less Traveled: Contract Manufacturing Differentiators (Part 1)

Topics: pcb assembly, Differentiators

Is Your PCB Prototype Assembly Process Slowing You Down?

Anyone trying to bring a new piece of electronics to market faces a major balancing act between trying to arrive at-market before the current generation of technology becomes last-gen, while still giving the product enough care and polish to appeal to buyers. The ever-speeding rate of new tech introduction has only made this harder, and we see the result all the time in stores and at trade shows: Half-baked products either rushed to market without proper testing, or being held back by design decisions that have already become antiquated.

Topics: pcb assembly, PCB

Improved Inventory Management Overcomes New Manufacturing Challenges

Have you taken a look at your supply lines and inventory management lately?

Good inventory management is probably more crucial in today's manufacturing world than ever before, and for plenty of reasons. There are a lot of challenges facing modern manufacturing, and a lot of them have to do with good inventory management and optimization.

With the right inventory procedures and the right manufacturing partners, you can reduce the costs on your electronics while helping guarantee they're of top quality.

Topics: pcb assembly, PCB assembling service

What You Need For Successful PCB Prototype Assembly Services

With the right contract electronics manufacturing partner, you can easily take a product all the way from the idea phase to store shelves! Good prototyping is the key to a successful product, and that's a process where both you and your manufacturing partner can contribute.

Your electronics manufacturer will be able to give you a lot of technical and engineering assistance, but a truly effective product needs to have focus to truly succeed. That's where you come in. With your knowledge of your market and customers, and your manufacturer's expertise, the PCB prototype assembly phase will help guarantee a great end product.

Let's talk a bit about what you should have in mind about your product, when talking to electronics prototyping services.

Topics: pcb assembly, pcb prototype assembly

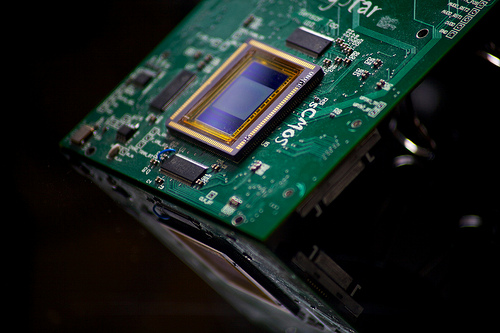

These days, electronics are everything. We are all wired in, whether for communication, work, or recreation. At the very heart of all of our electronics devices are the PC boards that allow them to operate and function as intended. As the years go by, the need for these boards to become more dense, more complex, and yet more compact has become even greater. As a result, electronics companies must understand and anticipate consumer needs so as to develop boards and products that will sell and satisfy. Despite the fact that most consumers will never give a second though to the boards running their devices, this is arguably the most important part of product development. Do you know what goes into the design and assembly of your PC boards? Read on to learn more.

Topics: pcb assembly, Contract Electronic Assembly, PCB Assembling

With Each Year, There's More Reason To Return To American PBC Assembly

It's no secret that reshoring is on the rise, with an increasing number of companies - even some of thebiggest - bringing their manufacturing services back home to America.

Topics: pcb assembly, pcb assembly manufacturer

What To Look For In Engineering Manufacturing Companies

If you're looking to jump into consumer electronics -or any electronics field- you've got more options than ever before in manufacturing partners. When there's an entire globe of electronics factories to choose between, how do you find the engineering manufacturing companies who fit your needs?

Topics: pcb assembly, engineering manufacturing companies, design manufacturing

Why Look Abroad For Assembly Solutions? Reshoring Is Growing! and it brings better hardware!

For awhile, it looked like the entire manufacturing industry was going to move abroad for their operations. The promise of super-cheap assembly solutions in China or Vietnam or other low-cost countries lured plenty of businesses overseas. When a company could get manufacturing done for one-fourth – or less – of domestic services, it made a compelling financial argument.

Topics: pcb assembly, assembly solutions, American based product assembly

4 Types Of Electronic Contract Manufacturers To Hire

Have you been thinking about hiring a third party manufacturing company to assist you with the design or assembly of your electronics? If so, it is very important that you understand what to look for in a quality and long-lasting business partnership. But with so many options, how can you even know where to begin? In order to help you narrow down your options and make the best decision for your operation, here's a look at the four types of electronic contract manufacturers that you should be looking to hire.

1. PCB Assembly Manufacturers

Technology is continuously evolving, and as it does, it is shrinking. Consumers today are demanding electronic devices that, while more complex and functional, are also extremely lightweight and compact. In order for these systems to operate properly and efficiently, printed circuit boards (PCBs) must also become smaller, while being able to support increasingly complicated electrical connections and components. Designing and assembling these tiny PCBs can be challenging, time-consuming, and very costly to electronics operations with finite resources. In order for you to fulfill customer orders, stay competitive, and grow your business, you may want to consider working with professional electronic contract manufacturers. Skilled and capable outsource partners can hep you to overcome and obstacles that your team is meeting and can provide high-tech machinery that will ensure faster, more precise PCB assembly.

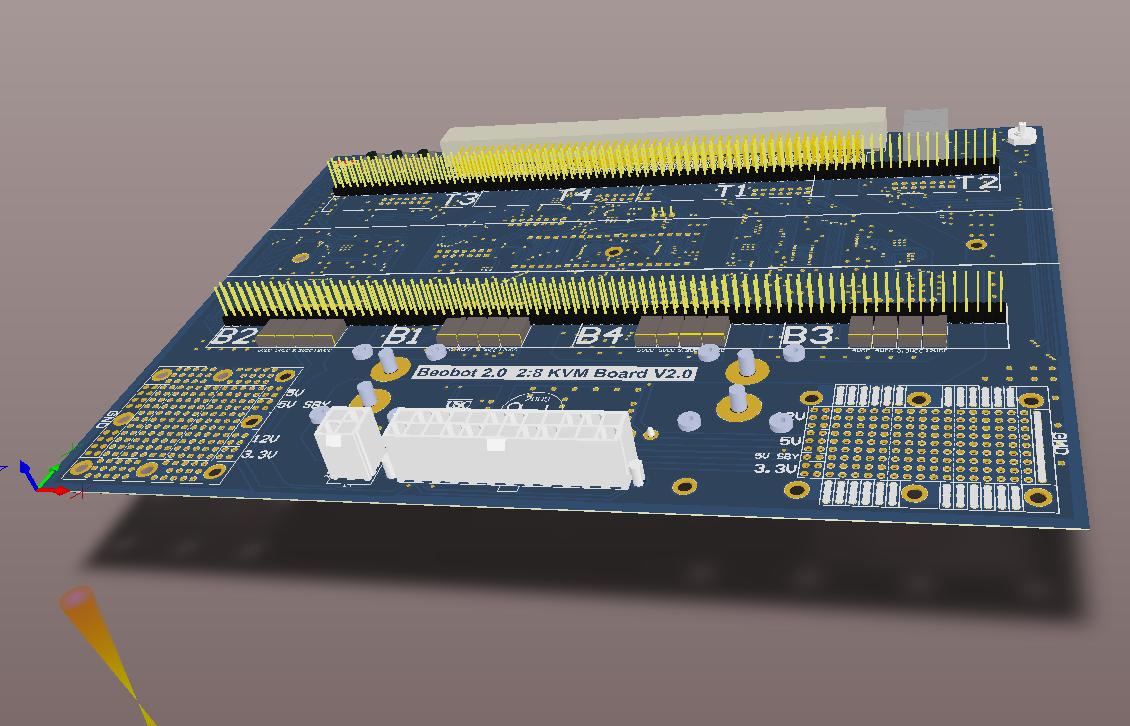

2. Systems Assembly Manufacturers

If your business is struggling with systems assembly, electronic contract manufacturers may be able to help. By choosing an experienced business partner that is familiar with all of the demands of system assembly, you can be the recipient of customized solutions that will help to manage your supply chain requirements. Regardless of what level of assistance you require, you can find relief and higher levels of success with the right contract manufacturer. Truly reputable third party companies will be capable of helping you with configure/build to order design schematics, assembly at the chassis, cage, or rack levels, custom cabling, board and system testing, and documentation management so that you can operate more efficiently.

3. Design and Build Manufacturers

There are many electronic contract manufacturers that only offer assembly services. Although this can help you to improve the speed of actually producing a fully designed product, it will not help you to improve the efficiency of your electronics. Despite the fact that your designers and engineers may be skilled at what they do, a fresh pair of eyes can always be of benefit to your business. Your third party design and build service may be able to pinpoint areas of your basic schematics that could be improved, thus saving you money on parts, or enabling you to create products that are easier for end-users to manipulate or that function more smoothly. Throughout the assembly and manufacturing process, your partner will be testing your products for operability and for problem areas that could be fixed. In this way, your business and your products will always be getting better.

4. American Based Manufacturers

At first glance, the electronic contract manufacturers that work offshore may seem like the more economical choice for a business partnership, but you should keep in mind that you get what you pay for. Although many foreign companies offer cheaper services, they also tend to cut corners and use bootlegged parts and system components during product assembly. And because cheap, unskilled labor is utilized throughout production, your devices may end up falling short of the expectations of yourself and your customers. To avoid these problems, it is in your best interest to work with American based companies that follow national manufacturing and assembly standards, and that utilize only high quality parts.

The right electronic contract manufacturers can be a tremendous asset to your business. By looking for these four types of manufacturers, you will enjoy more efficient daily operations, and will be able to provide better products to your customers.

Topics: pcb assembly, Electronic Contract Manufacturers, contract manufactuerers