Are you looking for a qualified electronics manufacturing service to partner with? Being able to differentiate between the best manufacturers and those that fall short can be a challenge. If you're not exactly sure what non-negotiables to look for, we've put together these nine factors that you should insist upon before partnering with an electronics contract manufacturer.

Mission Critical No. 1: Industry Experience

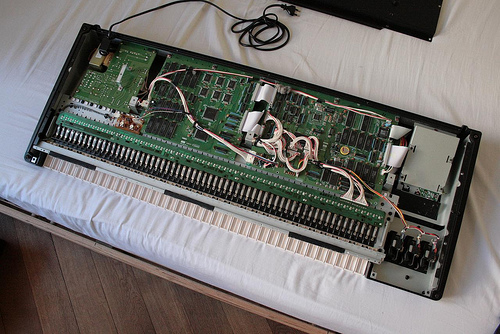

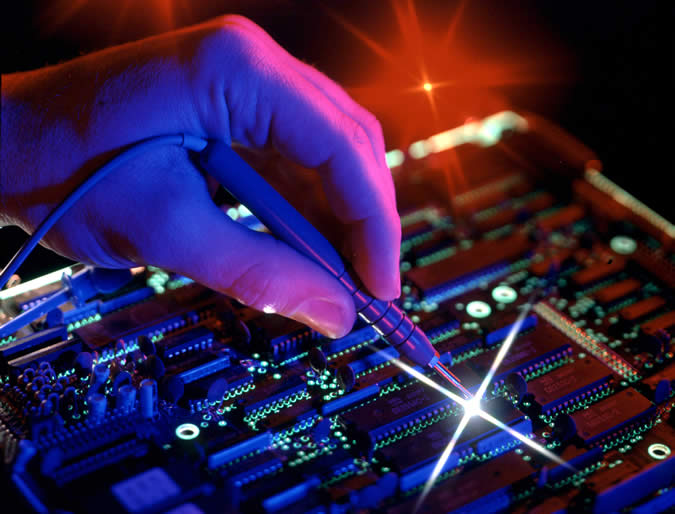

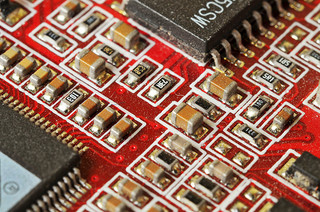

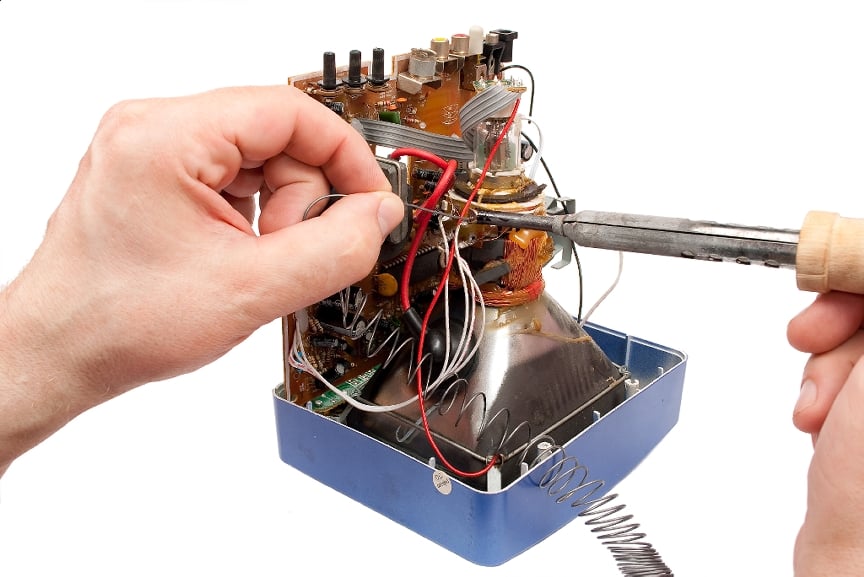

It is always in your best interest to partner with a contract manufacturing company that has an extensive history in the electronics industry. Those businesses that are well-established can be counted upon to provide high quality work, and will take pride in each board that they design and produce. Don't hesitate to ask your prospective manufacturer about how long they have been in business, who their core customers are, awards they have received, etc.