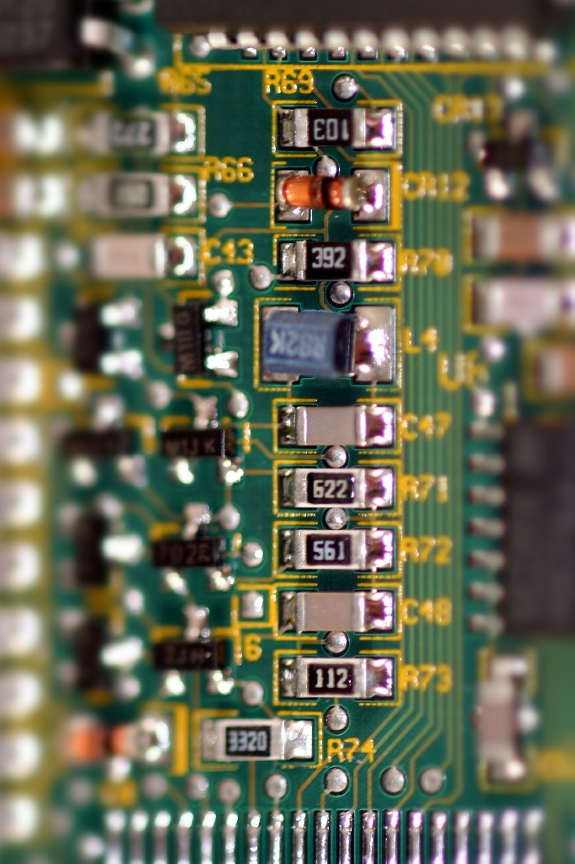

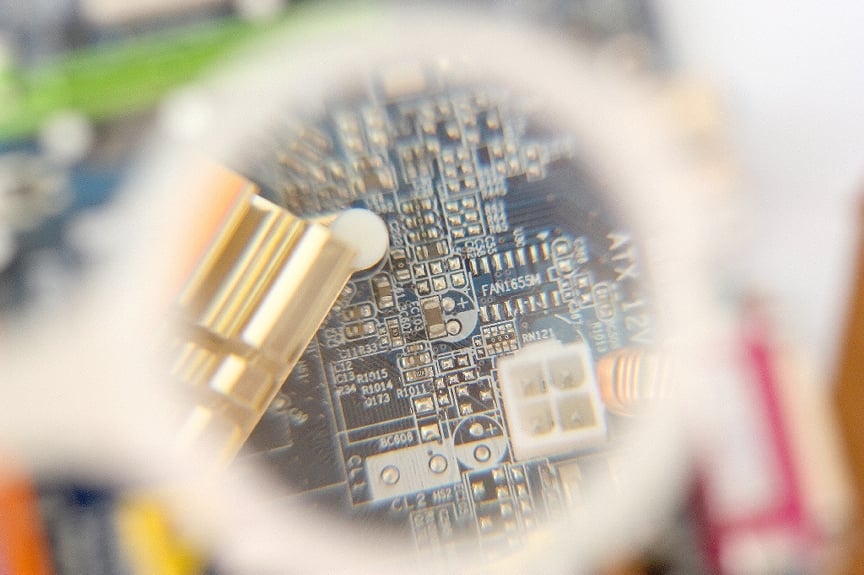

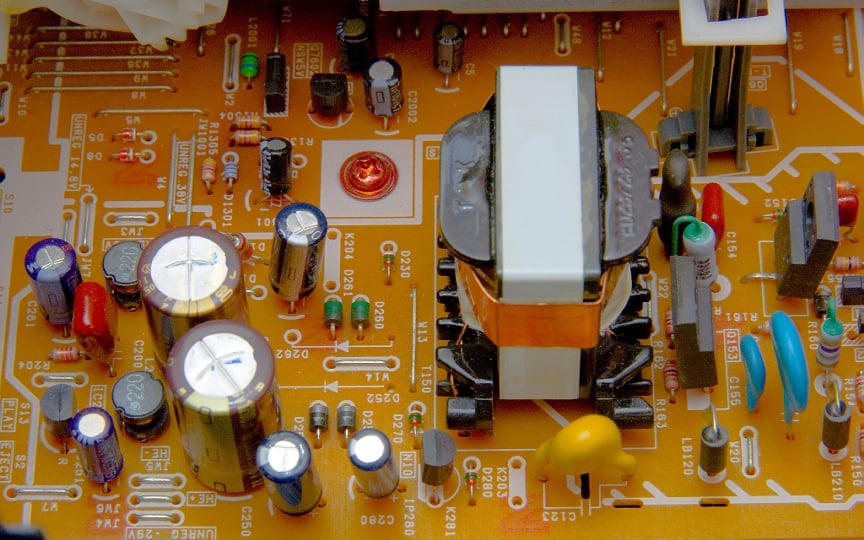

If you've been thinking about soliciting the help of a third party PCB assembly manufacturer, you're not alone. Many small and medium sized electronics businesses are realizing how beneficial it can be to partner with a contract manufacturing service, both as a means of saving money and improving the quality of their finished products. Despite the fact that there are many such contract manufacturing services, though, it's important that you are aware of what to look for before partnering with another company. This will ensure that you get the most bang for your buck, and preserve the integrity of your boards, enabling yourself to move forward and grow. If you're not sure how to go about reviewing your prospects, take a look at these "dos" and "don'ts" to selecting a PCB assembly manufacturing service.

DO Consider Location

Some businesses make the mistake of turning their eyes overseas when looking for a contract manufacturing company. In many cases, offshore companies will charge less money for PC board assembly services, but there's a reason for that. Offshore companies don't always adhere to the same safety and labor standards that we value in the United States. Counterfeit parts may be utilized in order to shave off costs and cut corners. This could compromise the quality of your devices, and even make you liable for lawsuits. As a result, it's best to keep your sights on qualified American companies.