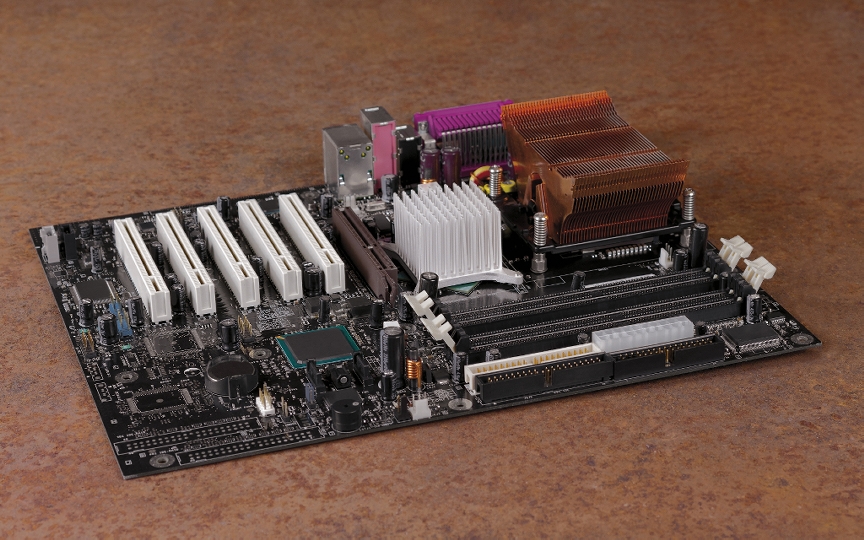

Over the past several decades, surface mounted technology (SMT) has grown in popularity and has widely replaced through-hole technology. But why is SMT so preferable to through-hole mounting, and can through-hole still be relevant in certain applications? By taking a few moment's to learn about both methods, you'll gain a thorough understanding of the unique characteristics of the two, the key differences between them, and what it is that makes SMT the preferred option.

Through Hole And Surface Mounted Technology - What is the Difference

Topics: assembly manufacturing, consumer electronics, smt production

Why You Should Look To SMT For Your Next Circuit Build

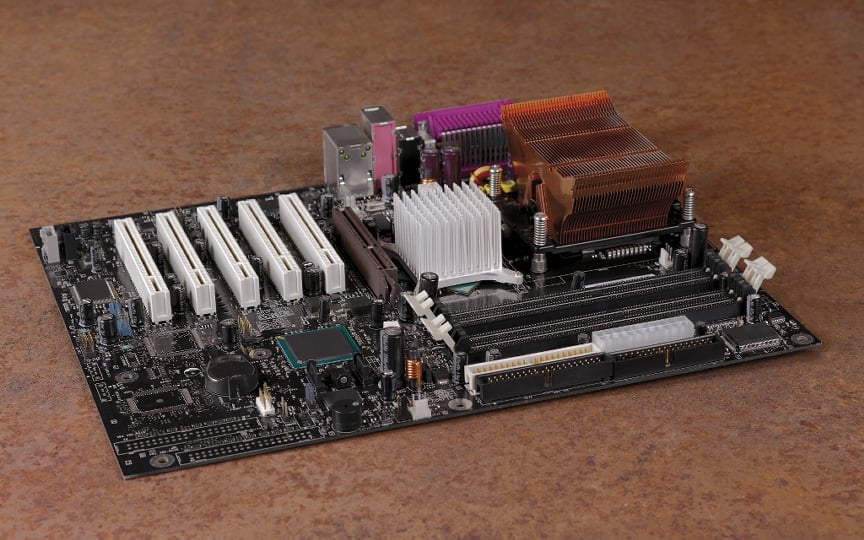

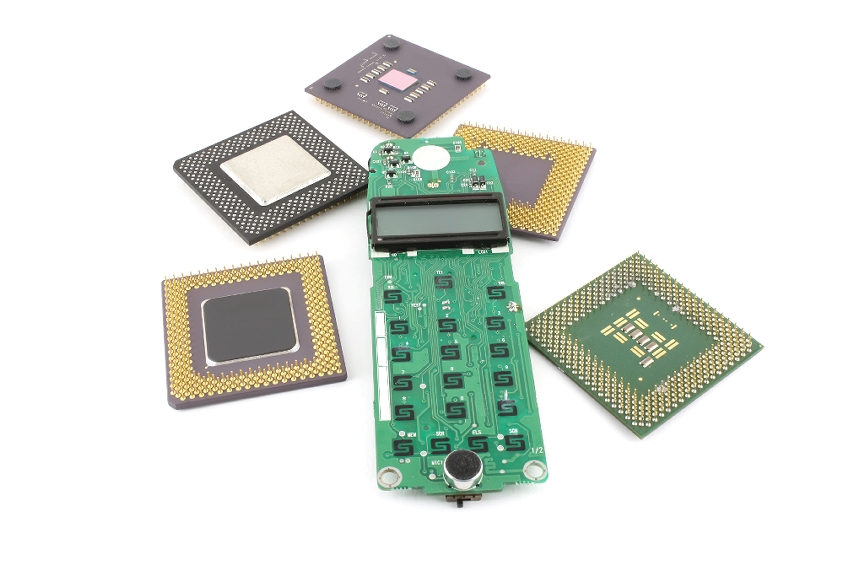

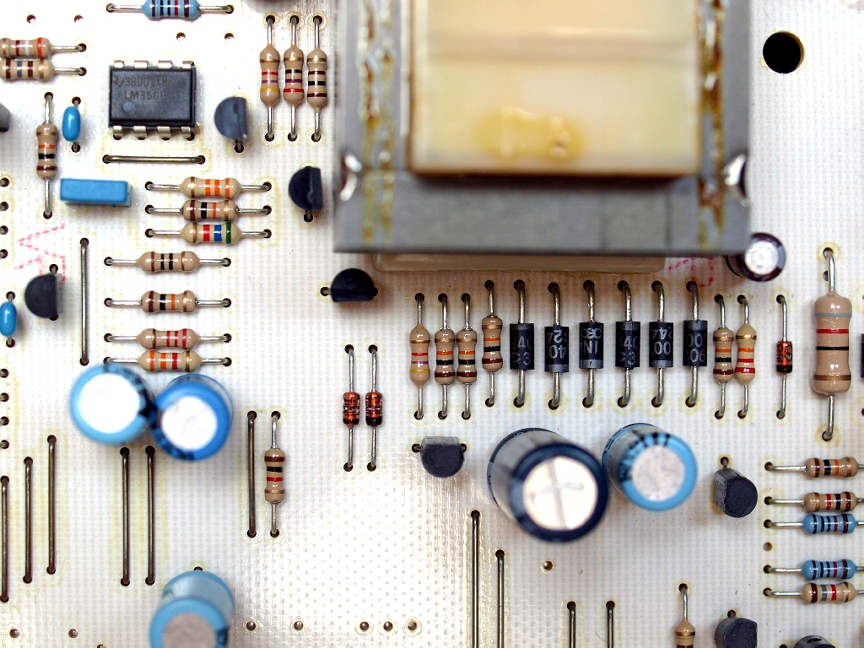

For most of the history of manufactured electronics, "through hole" printed circuit boards have been the standard. The idea has been effectively unchanged since the 50s, although there've been improvements in size and manufacturing quality. A through-hole circuit board needs holes drilled through it for connections and circuitry to pass through.

Topics: assembly manufacturing, consumer electronics, smt production

How Contract Manufacturers Help You Stand Out

From time to time, we all need a little bit of help. As a business owner, though, you may tend to pride yourself on your independence, and have a strong desire to keep all of your processes in-house. But what if soliciting design, assembly, testing, and fulfillment services could actually help you to grow your company an enable to you bring in more cash? That would probably grab your interest, and it has, indeed, peaked the curiosity of other small to midsize electronics businesses. A growing number of companies are turning to contract manufacturing services as a means of improving their own existing business models. Could this be a viable solution for your needs? If you're on the fence, take a look at 6 of the many ways in which a contract manufacturer could help to improve the development of your electronics.

1. Knowledge & Experience

Topics: assembly manufacturing, electronics contract manufacturing, assembly manufacturing firm

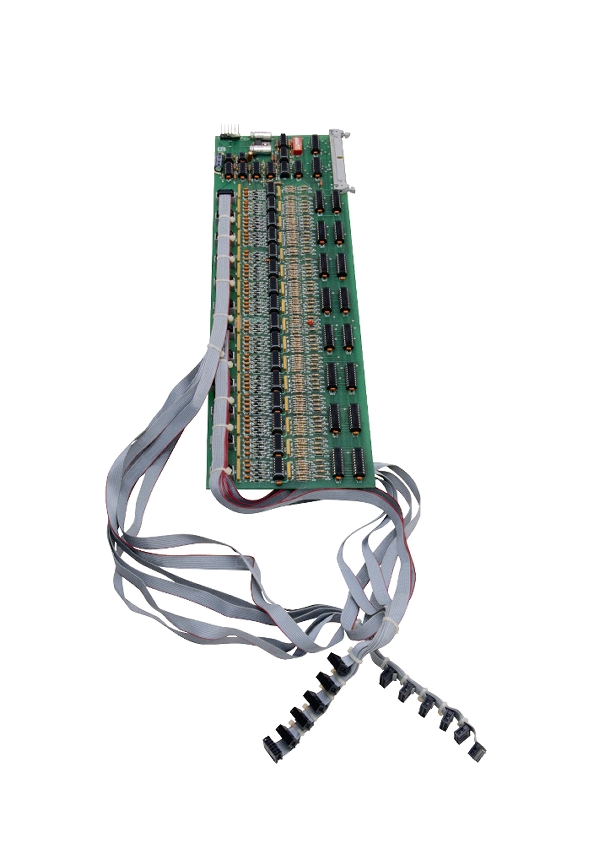

PCB Assembly & Manufacturing - You Know the Drill

It may seem like ancient history, but there was a time not so-very long ago when printed circuit boards were drilled with a simple drill press. An operator would repeat the process of manually moving the panel to the exact X and Y coordinates before pulling a lever and drilling an individual hole. Fast-forward to today and consider the fact that our modern PCBs often require more than 10,000 drill hits in all different sizes. Just imagine how long it would take an operator to complete one measly project using the old methods of drilling! Fortunately, the process has been simplified significantly throughout the years. Let's take a look at how our methods have evolved, and what drilling a PCB entails today.

Topics: assembly manufacturing, inventory management, contract electronics manufacturing

Electronic Design Services From Concept To Completion

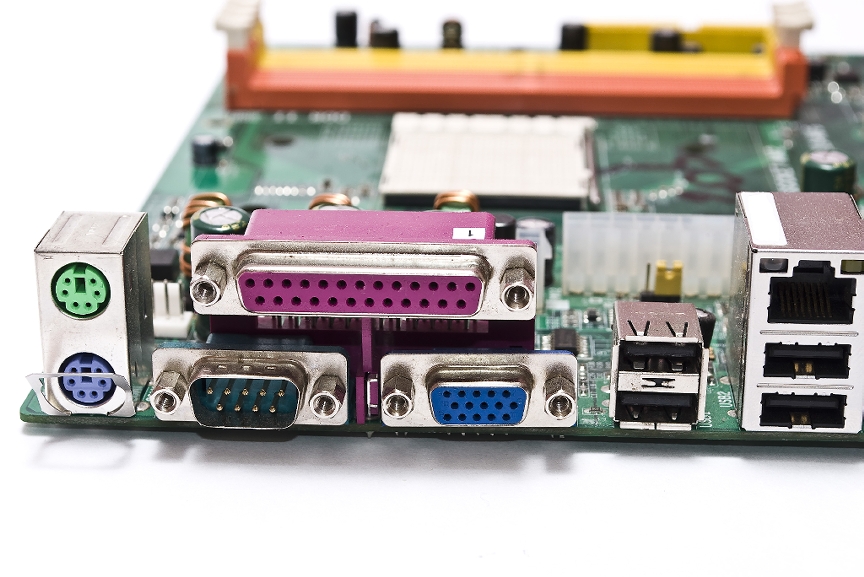

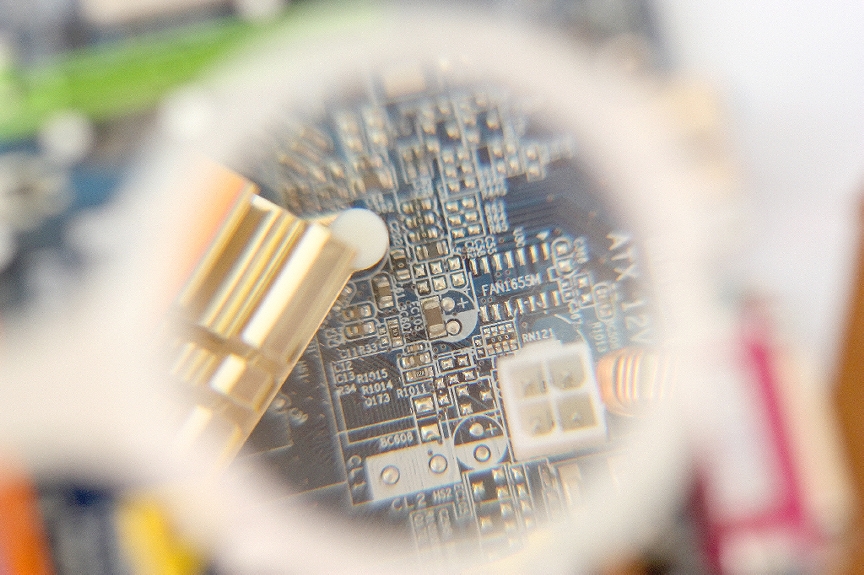

The design of printed circuit boards (PCBs) is one of the most important steps in manufacturing a quality electronic device. The functionality and efficiency of your electronics depend on the design and layout out of the board (or "brain") of the gadget, meaning that nothing can be left to chance. Through careful attention to detail, the board can be designed to meet all product specifications without wasting any space or utilizing excessive components. This enables the device to remain as compact yet information-rich as possible, meeting the demands of the consumer marketplace. But do you know what goes into superior electronics design services?

Topics: assembly manufacturing, pc board repair, electronics design services

Who Comes Out On Top Between SMT vs. Through-Hole Mounting

As technology continues to evolve, we must work to find ways to keep up with it. Although through-hole mounting or technology was the predominant option for developing printed circuit boards (PCBs) for decades, today's consumer demands require electronics manufacturers to embrace new technologies as a means of developing compact yet highly dense boards. The most popular solution has been surface mount technology.

Topics: assembly manufacturing, consumer electronics, smt production

It's not uncommon for small to midsize electronics companies to seek out the assistance of a contract manufacturing vendor as a means of reducing the time, costs, and other burdens associated with the production of PC boards. Contract manufacturing businesses exist all throughout the world, providing companies like yours with many options. Unfortunately, while many offshore contract manufacturers offer lower prices than their American competitors, the quality of their boards are often subpar. But what is it, exactly, that makes American businesses better and sets them apart? This post will take a deeper look at why you should only consider partnering with an American manufacturing service.

6 Reasons to Hire American Contractors

Topics: assembly manufacturing, contact manufacturers, assembly manufacturer

Topics: assembly manufacturing, consumer electronics, smt production

From Dream to Reality: PCB Prototype Assembly Services

The evolution of our world's technology is truly astounding. In the past decades, we've made great leaps and bounds in terms of what our electronic devices are capable of accomplishing, and things are only getting better. Technological engineers and electronics designers are continuously dreaming up new ways to improve existing products, as well as completely original ideas for simplifying every day life and tasks. But how does this process occur, exactly?

Every bit of technology - from the smallest, consumer electronic gadget to complex healthcare and aerospace units - begins with an idea. From here, plans can be made to develop a working prototype in order to test the capabilities of the device and to determine whether the idea is worth investing in, or how it can be further expounded upon in order to make it more operable, functional, and efficient. Every step in designing and assembling the prototype is essential to enabling the simple dream to become a reality. To give you a better idea of the process, this post will walk you through the life cycle of a prototype.

Topics: assembly manufacturing, assembly manufacturer, pcb prototype assembly

5 Saving Money Without Sacrificing The Quality Of PCB Assemblage

It really doesn't matter what type of business you're in - money is a common stressor for all of us. Despite the fact that the economy is improving, the majority of American industries are constantly looking for ways to scale back their costs and improve profit margins without sacrificing the quality or integrity of their work. Still, this is often much easier said than done. Finding areas where you can safely and effectively reduce spending while still keeping your customers happy with excellent products and services isn't as simple as it may seem, and it can be especially problematic in the electronics sector.

Topics: assembly manufacturing, American PC Board Assembly, PCB Assembling