Zentech was recently featured in Military & Aerospace Magazine in the article, Contract Manufacturing: there when you need it, and includes insight from Matt Turpin, Zentech's CEO and President.

Zentech Featured in Military & Aerospace Electronics Magazine

Topics: contract manufacturing

A Single-Source Contract Electronics Manufacturer Streamlines Your Products

One unfortunate byproduct of the offshoring boom of the 90s-00s was the maze of sub-contractors it often created. If you've gotten stuck in this trap, there are alternatives!

The Many Problems With Multi-Sourced Electronics Manufacturing

It's something we see a lot of clients dealing with, when they come to us. They've got one contract electronics manufacturer handling prototyping, and another group handling manufacturing, and another one developing software, and (usually) yet another party handling their post-sale support work. Sometimes even minor aspects like documentation end up outsourced to third parties or freelancers. On top of that, many of those contractors may have sub-contractors of their own which the original client may or may not know about.

Topics: contract electronics manufacturer, contract manufacturing

Keep Your Contract Electronics Manufacturing Safe By Staying Local

We spotted a new story this week that once again highlights how risky it is, outsourcing contract electronics manufacturing to China. It's just another example of why modern businesses need to be looking to manufacturing centers with strong IP protections.

Stories of failed Kickstarter projects are a dime-a-dozen, but the saga of The Dot is slightly different. The pitch was simple: Affordable < $100 Bluetooth earbuds stored in a self-charging tube roughly the size of lipstick. The Kickstarter reached its funding goal within a matter of hours, and was on track to have plenty of excess funding. Then the entire project was shut down, and all pledges refunded, because Kickstarter decided that The Dot was a re-sold Chinese product.

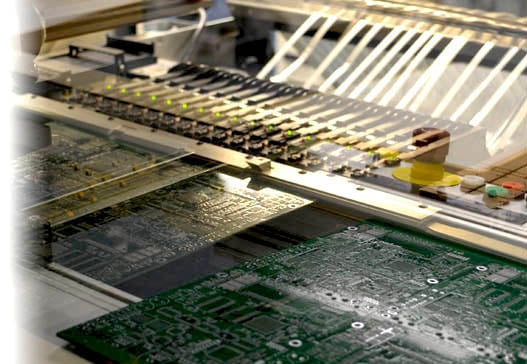

5 Characteristics Of A Great Contract Manufacturer

As a small to mid-sized electronics company, you may find yourself struggling, from time to time, to keepup with the large brands and businesses. While these "big fish" game players may be able to afford to employ a large staff of skilled designers and engineers, and stay on top of the latest and greatest assembly machinery, you may not have the same resources available to you. This is not an uncommon problem. To find success, many SMBs choose to contract the production of their PC boards out to a third-party manufacturer.

Topics: contract manufacturing, American based product assembly

Electronic Contract Manufacturing Companies, What To Expect From The Best

Today, a growing number of small to mid-size electronics businesses are making the decision to outsource some of their work to third parties. But while there are plenty of electronic contract manufacturing companies for you to choose from, it's important to understand that they are not all equal. How can you be sure that you are partnering up with a reputable business that you can truly put your trust in? To help you narrow down your options, here's a look at 10 things that you should expect from the best electronic contract manufacturing companies.

Topics: contract electronics manufacturer, contract manufacturing, electronic contract manufacturing companies

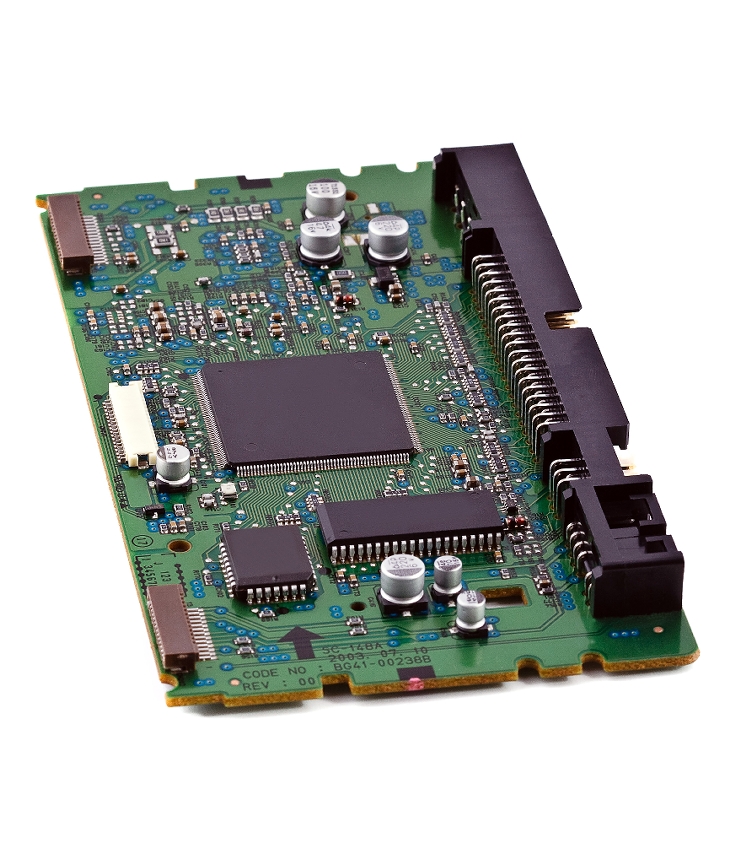

Quality Begins With Contract Electronics Manufacturer

Just like with all of your products that are assembled and shipped off to your clients, you want every single piece of component and part of your designs to be associated with quality. Who doesn't want to have the best of the best when it comes to their manufactured parts? Your clients trust that you're providing the best service to them, so why not expect the same kind of service and top notch quality in parts when it comes to your contract electronics manufacturer?

Topics: contract electronics manufacturer, contract manufacturing, contract electronic manufacturing services, contract electronics design

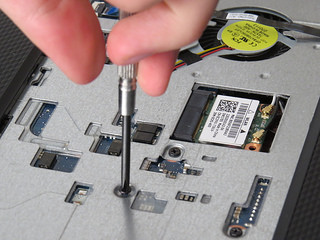

How Contract Electronics Manufacturing Modernizes Processes

Miniaturization, Nanotechnology and testing of micro-circuits are no easy task, they can take days to complete, which most manufacturing and assembly departments do not have, the cost overrun alone can dent into your company's strategy, which is why you need to modernize your manufacturing process, the only question is how.

Topics: contract manufacturing, manufacturing services, contract electronics manufacturing

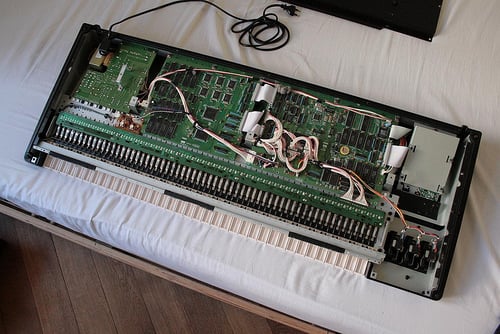

Contract Electronics Manufacturing: Parts For Every Process

For every single process put into your product by an electronics manufacturing company, there is a specialized part to make sure it works. Every circuit board and other electronics that go into bigger machines are all put together by parts that are included in every single part of the process, ensuring that everything works once it is completed and is in top notch shape for your client.

Topics: contract manufacturing, manufacturing services, contract electronics manufacturing