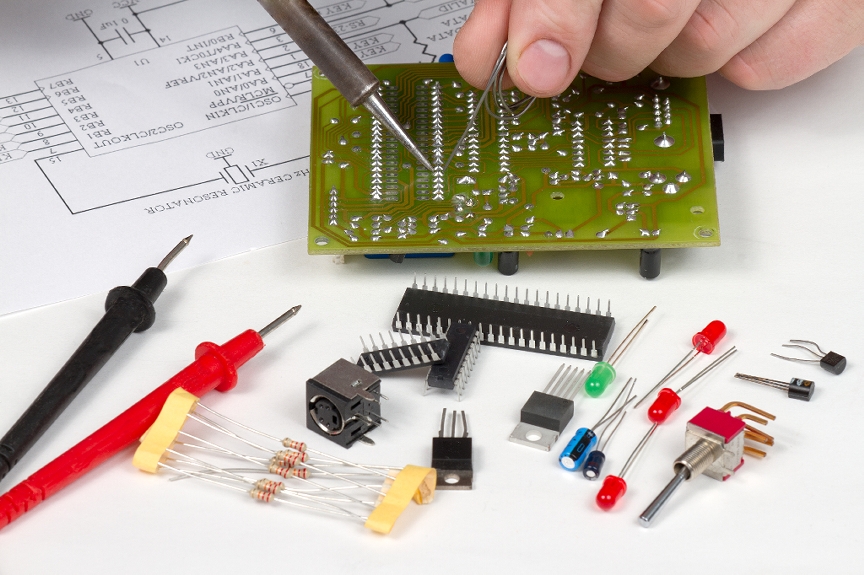

Even the best electronics companies aren't free from the possibility of a defect or fault developing within their products. Although major problems may arise from time to time, though, it seems wasteful to completely scrap a circuit board when only one component is causing the fault. Unfortunately, many smaller businesses do not have the time or the resources available to troubleshoot for the problem and make the necessary corrections. Professional PCB repair services can help by shouldering this burden for you. By taking the time to consider the issues that a contract repair service can provide and how it can work to your benefit, you could significantly improve your company's efficiency and effectiveness.

Matthew Turpin

Recent Posts

PCB Repair Services Make Old Boards Brand New

Topics: electronics design services, PCB Repair Services, PCB design services

Engineering Manufacturing Companies, Why They're Coming To The US

After the manufacturing industry took a hit during the recession, a great deal of workers found their jobs being handed to off-shore businesses. The tides, though, are definitely turning, bringing a growing number of engineering manufacturing companies back home to American soil. Why the sudden turn around? And what is the outlook for the future of the engineering and manufacturing industry in the U.S? Here's a closer look at the facts.

Topics: electronic manufacturing company, electronic design and manufacture, engineering manufacturing companies

No Problem Too Big For Electronic Manufacturing Solutions

Regardless of the specific industry, every business faces its own unique sets of problems and challenges. For those in the technology sector, though, electronic manufacturing solutions can be found by contracting with a third party design and manufacturing company. No matter how big the issue may seem to you, a professional electronic manufacturing solutions provider can help you to overcome it and succeed. Here's a closer look at some of the most common problems in the electronics industry, and how they can be resolved.

Topics: electronic manufacturing company, Electronic Manufacturing Solutions, electronics manufacturing service

How To Find A Reliable Electronic Manufacturing Company

Is your business in need of a reliable electronic manufacturing company? Although you have plenty of third party companies that would be interested in getting your business, there are some that are more qualified than others. So how can you tell the difference? It's actually easier than you may think. By following these 10 simple steps, you can find an excellent contract manufacturer with total confidence.

Topics: electronic manufacturing company, electronic manufacturing, electronic manufacturing services industry

Electronic Design And Manufacture, What Services Are Involved?

Could making the decision to contract with an electronic design and manufacture company help improve your business? Although you may think that you have all of your bases covered, you might be surprised to learn what a third party agency could do for you. Regardless of whether you are in need of complete design and build services, or if you just need a little assistance in fine tuning your processes, you could benefit significantly from a partnership with a contract manufacturer. Here's a quick guide to what you can expect from both the design and manufacture side of working with a third party contractor.

Topics: electronic design and manufacture, electronic design, design and manufacture services

Creating Electronic Manufacturing Solutions

Like all other businesses, yours has probably been faced with challenges and obstacles from time to time. Although there are many instances in which these problems can be overcome in-house through a little resourceful thinking, it is important to have the ability to recognize when a solution cannot be found on your own. It is the companies who possess the foresight to anticipate issues and form alliances with a qualified contract manufacturer who generally find the most success.

Topics: electronic manufacturing services industry, Electronics Contract Manufacturer, Electronic Manufacturing Solutions

PCB Assembly Manufacturers: Better Than Doing It Yourself

As a business owner, you pride yourself on your independence and self-sufficiency. But while your "can-do" attitude may have helped you to get where you are today, you may find that asking for help could take you to an even higher level. Third-party PCB assembly manufacturers can help to shoulder some of your business's burdens, improve the quality of your products, and lower your overall spending. Here's how:

Surface Mounted Technology Makes Manufacturing Processes Smooth

Although still a relatively newer concept, surface mounted technology (SMT) is quickly becoming the "go-to" method for mounting components to a printed circuit board (PCB). Are you familiar with SMT processes? Many electronics companies are comfortable with the tried-and-true through-hole mounting process, but SMT can make things a lot simpler and more efficient. To prove this point, here's a look at what surface mounted technology actually is, and when it can be used to make processes smoother for your business.

Topics: smt production, surface mount technology, surface mounted technology

When To Employ A PCB Design And Manufacture Company

Although your electronics business has been doing well, you may be feeling that it's time to take things to the next level and start growing. Unfortunately, trying to grow too quickly, without the necessary assistance and resources, can create serious problems. It is because of this that many small and medium sized companies choose to contract with PCB design and manufacture services for help in achieving their objectives. But is working with an outsource operation right for you? Here are six examples of instances in which you should think about hiring a contract manufacturer.

1. You need to streamline your products

Are your current products as efficient as they could be? Your in-house engineers may be knowledgeable, but if no outsiders have taken a look at your plans in the recent past, they may be overlooking factors that could make your devices even better than they are right now. If you feel that your business could benefit from cutting down the parts and materials necessary to manufacture your electronics, you may want to contract with a reliable PCB design and manufacture company for some assistance. Upon reviewing your schematics and existing PC boards, your partner company may be able to point out ways in which you could improve your product's functionality while streamlining its basic design, thereby saving you time and money.

2. You are struggling with design flaws

From time to time, we all get stuck on a problem. If you and your team are struggling to either pinpoint the root of a fault, or are unable to come up with a workable solution, it's time to seek help. By recruiting industry experts, you'll have the privilege of viewing the issue from a whole new perspective so that you can resolve them faster and get your perfected products out to your clients.

3. Your business is lacking in resources

Smaller electronics companies may be at a bit of a disadvantage as compared to their large scale competitors. Because the "little guys" have fewer financial and labor resources, it can be difficult to keep up with the ever-changing market and advancements to technology. If your company isn't able to employ the manpower necessary to create and produce PC boards, or if you don't have the ability to maintain expensive assembly equipment, you could benefit from hiring a PCB design and manufacture service. By contracting with a third party, you can take advantage of their resources without committing to permanent laborers or equipment.

4. You need to quickly produce a prototype

In many cases, our brains work faster than we can keep up with them. If you've got great ideas for a new product and need to demonstrate its abilities to your clients quickly, you may need a professional PCB design and manufacture agency to help you get your prototype developed and functioning properly. Through careful planning and testing, you can rest assured that your prototype will impress your audience so that you can generate future business.

5. Your production orders have increased

Has your business bitten off a bit more than it could actually chew? If you're struggling to keep up with the demands of your customers, a contract manufacturer can help you to automate the assembly process so that you can produce your PC boards and other devices faster, without sacrificing quality or precision.

6. You would like to reduce warranty replacement costs

How do you handle defective or faulty products? If your current solution is to simply ship off a replacement unit to your customers, you could be losing a lot of money. A PCB design and manufacture company that offers a customer repair and return depot will be able to scale back these expenses by taking the time to troubleshoot the device, correct the issue, and get it back to the client in no time.

Could you benefit from working with a PCB design and manufacture service?

Topics: engineering design services, PCB Design And Manufacture, PCB Repair Services

Surface Mounted Technology, What Is It All About?

What is Surface Mounted Technology (SMT)?

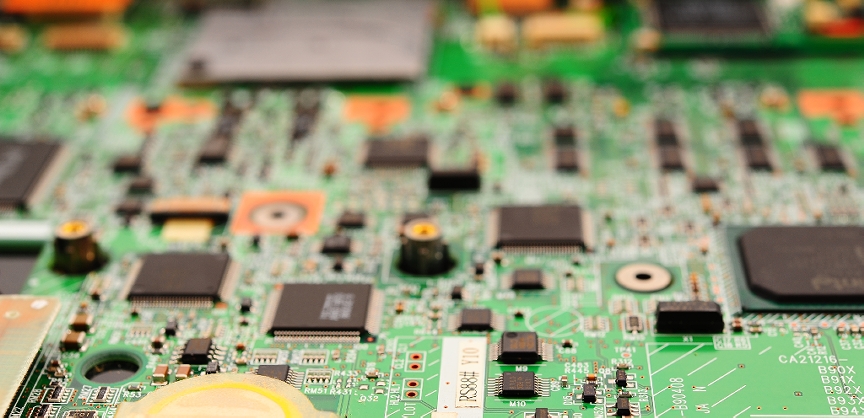

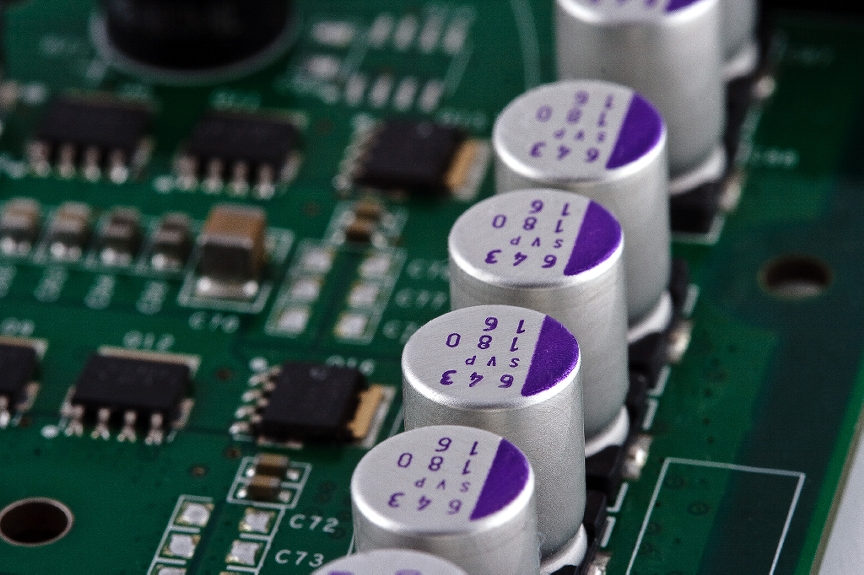

In SMT, components are placed directly onto the surface of a PCB in order to create what is known as a surface mount devise (SMD). Due to its efficiency and effectiveness, SMT has widely replaced through-hole technology methods for constructing PCBs, however, both methods can be utilized on the same PCB. This is because there are some components that are simply not suited to surface mounting. These components might include large transformers and heat-sinked power semiconductors. Generally speaking, SMT components are smaller in size than through-hole units as they have smaller leads or do not have any leads at all.

What are the Advantages of Surface Mounted Technology?

The primary advantage to SMT, of course, is size. Because today's electronics are expected to be more compact, there is an increase in demand for smaller units. SMT makes this possible. But despite the fact that these units are not as bulky as older devices, there is actually a much higher component density, as well as more connections per each component. This means that electronics can be more efficient and advanced than ever before, while still being as compact as possible. Fewer holes need to be drilled into the boards which leads to faster and more automated assembly processes, and the fact that components are able to be situated on either side of the circuit board simplifies things further. On top of this, there are many SMT parts and components that actually cost less than their through-hole counterparts. All of this results in a lower initial cost, less time required for setting up and production, reduced manufacture cost, and a more efficient use of time.

What are the Disadvantages of Surface Mounted Technology?

Unfortunately, there are no perfect or fool-proof manufacture processes, and SMT does have its drawbacks as well. As an example, SMT is not suited for any large, high-power/high-voltage parts. Because of this, SMT and through-hole construction may need to be combined for better results. Additionally, the small size of SMDs can create issues, in that the solder joint dimensions continue to grow smaller as advances are made toward ultra-fine pitch technology. Ultimately, this means that less solder is able to be used for each joint which can result in voiding, and integrity issues. The solder connections of SMDs are also capable of being damaged by plotting compounds as they go through thermal cycling. Lastly, SMT should not be used as the sole attachment method for any components that may be subject to ongoing mechanical stress, for instance, connectors that are utilized to interface with external devices which are often attached or detached.

When Should Surface Mounted Technology be Used?

Because of its many benefits, the majority of products manufactured at this time utilize surface mounted technology. Despite this, we have seen that SMT is not suitable in all cases. As a rule, SMT should be considered if:

- Your products must be very small/compact

- Your products must be able to accommodate large volumes of memory

- Your final product needs to be sleek and light despite component density

- Your product will need to be able to function at high speed/frequencies

- You need to produce large quantities with automated technology

- Your product should only transmit very little noise (if any at all)

- Your product must be able to accommodate a great deal of large, high lead-count complex ICs

Topics: contract manufacturing company, PCB Assembling, surface mounted technology