If you're shopping around for a contract manufacturing company, you're well aware of the fact that you have many options to choose from. Unfortunately, though, not all manufacturing services are equal. In order for your business to truly thrive, you must take the time to find a partner company that is passionate about providing quality services and products. Here's a closer look at what it is that you should expect from your manufacturing agency.

Open Communication and Collaboration

The best manufacturing services will always keep the lines of communication open between themselves and their clients. It should never be difficult for you to get in touch with your contract manufacturer to set up a a consultation, to review design schematics, to discuss any issues or deadlines, or to find out the status of the production of an order of electronics devices. On the other side of things, your manufacturing service should also contact you with regular updates, or to talk about any problems that have been encountered or changes that have been made to improve the design of your product. Regardless of whether you are leaving product design completely in the hands of your contract manufacturer, or if you're looking to collaborate with experts on ways to improve your schematics, no action should ever be taken without your approval.

Excellent Parts

Your electronics devices cannot function as they should unless the parts used to construct them are top notch. Unfortunately, this is the area where many manufacturing services fall short. Often, electronics companies look overseas to outsource the manufacture of their products because the services rendered are typically cheaper. But when making decisions like these, you must remember that you get what you pay for. Many offshore manufacturing services are able to lower their price points because they are cutting corners and utilizing bootlegged parts. This can create serious problems with the functionality of your devices and can sometimes even result in safety issues. Ultimately, your customers will be dissatisfied with their products, leaving you with the costly burden of replacing their devices or even going back to the drawing board as you are required to recall the product altogether. In the end, you will have lost money and your reputation will have been severely damaged.

Choosing to work with an American company with a solid reputation, on the other hand, will ensure that the parts used in the production of your devices will be of the highest quality possible, so that you can be proud of the products that you put on the shelves for your consumers.

Technologically Advanced Machinery

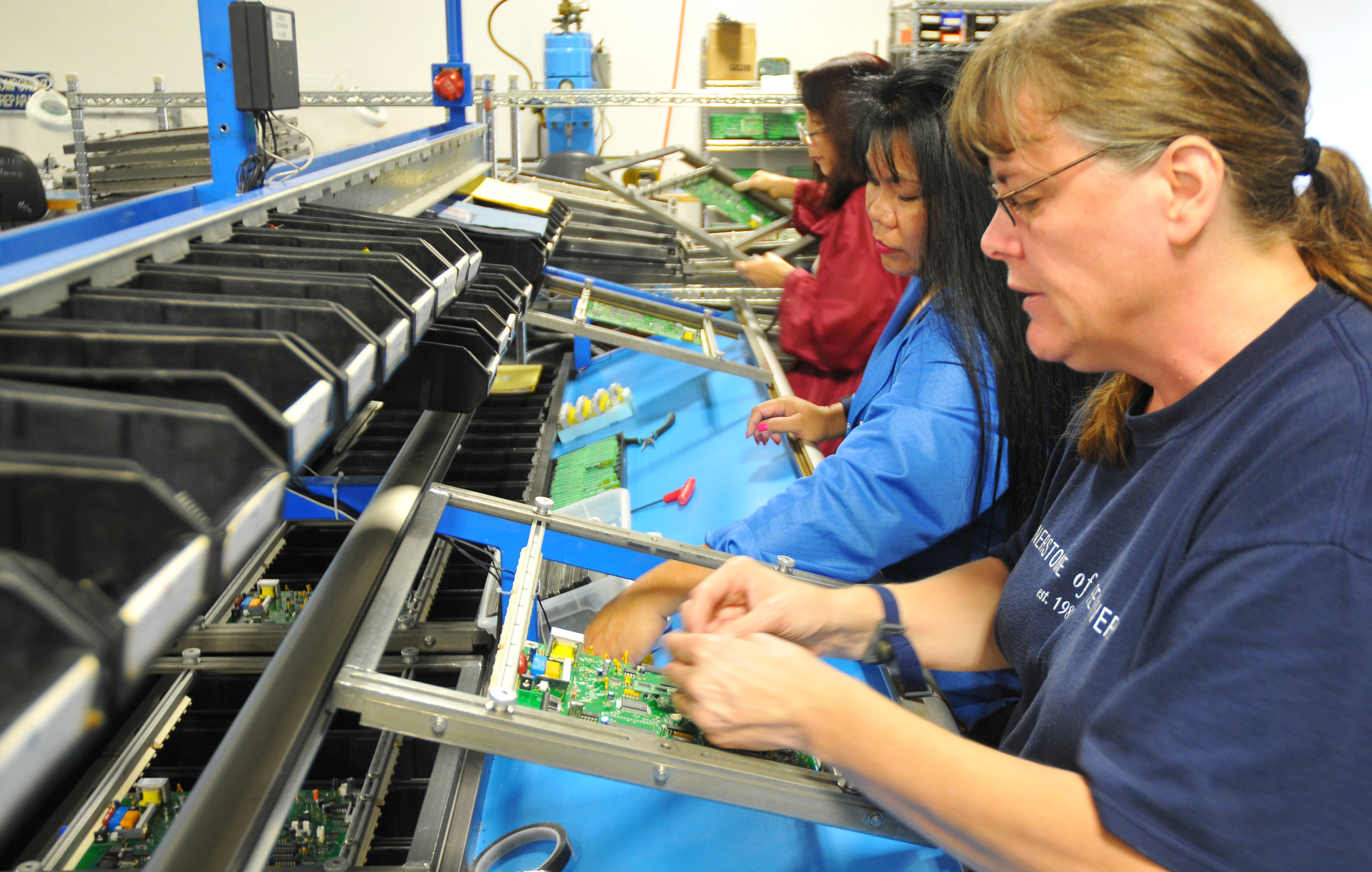

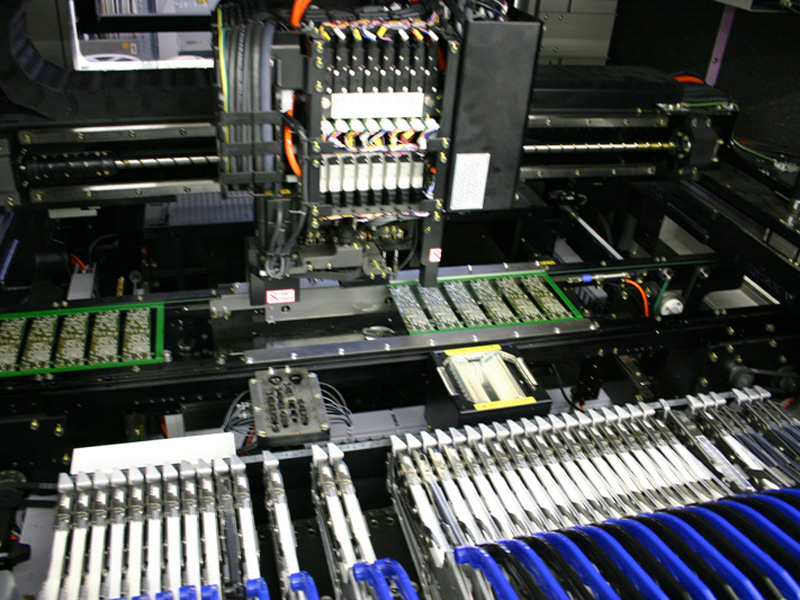

When choosing between electronics manufacturing services, take a look at the types of technology and machinery that they utilize during the production of complex devices. High-tech facilities will deliver the best products. Robotic arms, for example, are essential to manipulating very small parts in a way that is efficient and precise. Be sure that the product assembly process makes use of the latest and greatest equipment for quickly generating your product without detracting from accuracy and operability.

Quality Control

Professional manufacturing services will never allow your product to go to consumers without being carefully tested for functionality and safety. Be sure that your contract manufacturer has a proven process for checking over assembled devices to ensure that your customers will be fully satisfied with your electronics devices. In electronics manufacturing, there is no "good enough". In order for you to remain competitive and successful, your products must always be the best, and your manufacturer should understand this principle.

By insisting on these criteria, you'll find the best manufacturing services possible.

What To Expect From Top Notch Manufacturing Services

Topics: contract manufacturing company, manufacturing services, electronics manufacturing services

Contract Electronics Manufacturing: Providing You Phenomenal Service

As technology continues to evolve, so do the needs of your customers. Today's consumer market has higher expectations for electronic devices than ever before, demanding smaller, lighter, faster products for lower costs. Although some of the biggest electronics design and manufacturing companies may have the capitol and manpower to keep up with these customer needs, it may not be so easy for small to medium sized operations to do so. Fortunately, you don't have to throw in the towel and give up. Contract electronics manufacturing services help to level the playing field by offering phenomenal services at a reasonable price point that enables your business to grow and thrive. So what is it that makes a partnership with a contracted manufacturer such a wise investment? Here are three things that you can expect from your contract electronics manufacturing service:

1. Consultation Services

Regardless of where you are at in the design process, a professional contract electronics manufacturing service can provide valuable consultation services. Perhaps your company would prefer to keep designing and engineering in-house, while outsourcing only the production of your devices. It's still wise for you to keep the lines of communication open between yourself and your manufacturer. An expert outsource company will employ those who are highly knowledgable and who may be able to spot design flaws, inconsistencies, or areas that could be improve in order to maximize efficiency and customer satisfaction. By allowing your electronics manufacturing service to review your design schematics before production, they may be able to send the plans back to you for improvements that could end up saving your company a lot of money. On the flip side of things, a contract electronics manufacturing business can also be more "hands-on" throughout the design process. With highly complex electronics, you may need the help of your partner company to solve problems, or to design the device from scratch.

2. Advanced Manufacturing Technologies

With every year that passes, electronics are growing smaller and more complex, making them more difficult to manufacture. If your smaller electronics business is utilizing dated machinery or is putting devices together by hand, you could be struggling to keep up with marketing demands. In fact, these older processes could be costing you a lot of money, as so much time and labor is required, and more mistakes are likely to be made. Unfortunately, the purchase of newer machinery to constantly keep up with evolving technologies can be impossible for "underdog" companies. This is where contract electronics manufacturing services can help. By working with these types of companies, you can take advantage of the latest and greatest machinery, product assembly services, and robotics without having to purchase the equipment yourself. In this way, your products will be manufactured quicker and more precisely than ever before.

3. Quality Control

Of course, no product should ever hit the shelves or be available to consumers until after it has been carefully tested for quality. When you select an American-based and highly qualified contract electronics manufacturing service, you can rest assured that your devices will be checked for functionality and total precision. In addition to this, you will know that you can be proud of the devices that you are putting out in the world because your manufacturer will only utilize high quality parts for safety and operability.

Remember: You Get What You Pay For

If you're hoping to receive these three excellent services from your contract electronics manufacturing company, you must take care to invest your money wisely. Often, off-shore manufacturing services are very low cost, but that doesn't guarantee quality at all. Many of these companies are able to keep their price points low because they use boot-legged parts and shoddy craftsmanship. Selecting an American company with years of experience may initially cost a bit more, but customer satisfaction and the improvements to your sales revenue will pay you back in the long run.

Topics: electronics manufacturing company, contract electronics manufacturing, off-shore manufacturing services

How Can A Manufacturing Assembly Speed Up Processes?

If yours is like most other electronics manufacturing companies, you are constantly looking for ways to speed up your processes so as to run more smoothly and efficiently. Unfortunately, when everything is done manually or your staff and machinery are limited, you can find yourself bogged down by labor costs and lost time. So what's the solution? Even the smallest electronics companies can keep up with their larger competitors when they contract with the right, American based manufacturing assembly business. By choosing to work with a contracted manufacturer, you'll be able to speed up all of your processes while still turning out high quality products that will keep your customers happy. Here's a closer look at how this can be accomplished.

Fast and Cost-Effective Design

There's no need to labor over plans for weeks on end, without coming up with a workable and affordable solution. By choosing to work with a contracted manufacturing assembly partner, you'll also have the ability to receive input during the design process. With highly qualified and experienced individuals on your team, you can come up with a way to create a sleek, user-friendly electronic device that will be constructed with as few parts as possible. Fewer parts means less money spent, overall, and every penny counts. But this doesn't mean that the quality of your products will be reduced. Your business partnership will simply help you to discover the most affordable design and build strategies so that you (and your customers) can get the most value for your dollar. The biggest advantage here is that this can all be accomplished much quicker than when you work on your own, meaning that you can stay ahead of the competition by delivering better products to your consumers quickly.

Topics: manufacturing assembly, electronics manufacturing companies, speed up your processes

Why Should Your Company Use An Electronics Manufacturing Service?

Whether you're struggling to efficiently produce your electronic devices in-house or are just starting your business and are seeking an electronics manufacturing service, your primary goal is to find a partner that will help you to generate high-quality products in a way that is fast and cost-effective. You know that this is important, but if you've got a business partner or superior who is questioning the need to contract with a third-party manufacturer, you must be able to justify the investment. In order to get what you need, here are the top five reasons for working with an American electronics manufacturing service.

1. Design Products with Fewer Bumps in the Road

Creating small, complex electronics can be extremely challenging, and your team of engineers my struggle from time to time with problems that take them all the way back to square one of the design process. Unfortunately, when your staff have spent too much time examining a project, it may become difficult for them to see a solution that is right under their noses. Because of this, it's wise to bring in a fresh set of eyes, who may be able to solve the problem more quickly. In this way, your business is able to keep moving forward, instead of getting stuck on bumps in the road or required to scratch a design completely and begin again. Ultimately, this can save a significant amount of man hours, money, and stress.

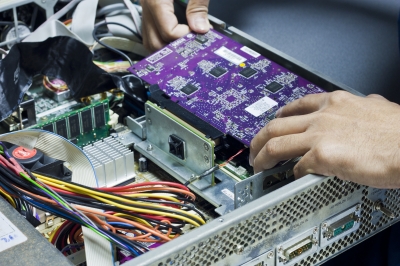

2. Make Use of High Quality Machinery and Parts

Sure, your company may use good machinery in the creation of your products, but in order to stay competitive with other businesses, you've got to have the best. By working with an electronics manufacturing service, you can take advantage of the latest and greatest technologies without having to purchase it yourself. Assembly solutions, for example, can streamline the process of manipulating tiny parts and pieces, making the process faster and more accurate from start to finish. And by choosing to work with an American manufacturer, you can rest assured that all of the parts used in the construction of your devices will be of the highest quality. In fact, your service may actually have connections to suppliers who can offer better parts for less dough.

3. Produce Fewer Faulty Devices

When you're able to produce your devices with the highest quality parts and machinery, you won't be throwing out entire batches of electronics as a result of errors. With fewer faulty devices on your hands, you'll be able to increase your profit margins and get the most bang for your buck.

4. Get your Products to the Masses Faster

Working with a professional electronics manufacturing service means that, from start to finish, your products will be designed, produced, tested, and shipped to end-users far faster than ever before. And the quicker you are able to get your devices to the masses, the faster you can start bringing in sales revenue and profiting. But faster doesn't mean reduced quality. Each of your devices will still be held to the highest standard so that you aren't hit with consumer complaints, warranty claims, or other related issues.

5. Scale Back on Your Spending

When you find a reputable electronics manufacturing service, you can spend less on product repairs. Broken or faulty equipment can be sent directly to your manufacturer for fast troubleshooting and fix-it jobs so that you don't have to lose money on warranty replacements. Additionally, you'll spend less time and money on shipping the faulty device to the manufacturer, waiting for it to be repaired, and having it shipped back to you before sending it to the customer. And after developing as solid relationship with your electronics manufacturing service, you may find that you begin to save money, as they are able to offer you discounted services for your loyalty.

Find out firsthand how an electronics manufacturing service could benefit your business. Are you ready to get started?

Topics: assembly solutions, electronics manufacturing service, third-party manufacturer

4 Reasons To Use A Contract Electronics Manufacturer

Due to the fast-paced nature of this world, it's no surprise that the electronics industry is as competitive as it is. Electronics companies are constantly pushed to reach beyond their limitations to create devices that are more compact and more advanced, while still keeping prices low. The expenses involved with creating new products, however, can make it very difficult to keep customer costs down or to make much of a profit. It is for these reasons that a growing number of companies are seeking out help from outsource vendors. But is this the best solution for you? If you're not certain, here are four key reasons that you should seriously consider working with a contract electronics manufacturer.

1. Gain New Insights

Although there is no doubt in your mind that your team is highly knowledgable and good at what they do, you should never convince yourself that you or your staff have nothing left to learn.Technology is constantly evolving, and new ideas and methods are continuously being developed in order to streamline the process of designing and building better electronics. A contract electronics manufacturer can bring these new concepts to the table, opening your eyes to a world of new possibilities. Your contract partner may be able to point out ways to adjust your product designs in such a way that production costs will be reduced, or your device will run smoother, and with a reduced likelihood for malfunctions or other issues. Additionally, an electronic contract manufacturer can help you to work out problems and kinks that your team has been struggling to resolve, so that you can keep your business moving forward and making money.

2. Take Advantage of the Most Advanced Technology

For the largest enterprises, it may not be as difficult to spend the money on advanced technological upgrades every year or two. For smaller and medium sized business ventures, on the other hand, this may not be possible. When your company's cash flow is tied up or somewhat restricted, it can be impossible for you to make the investment in the latest and greatest manufacturing machinery which, in turn, makes it very hard for you to keep up with the competition. A contract electronics manufacturer can "level the playing field" by offering your business access to more advanced technologies throughout the production of your devices. Robotic arms can be utilized to manipulate even the smallest parts with care and precision, so that human-error can be removed from the equation. Fast, accurate machinery will speed up the product assembly process without ever detracting from the operability of your electronics, so that you can stop wasting money on time and faulty equipment.

3. Improve Customer Satisfaction

By working with a contract electronics manufacturer, you can improve the quality of your products and ensure that your customers will be happier with their devices. This is not only due to the fact that the machinery and equipment used to manufacture these devices is so precise and advanced, but because the best parts are used, and all products are tested for quality. A good, American-based contract partner will never utilize bootlegged parts during the manufacture process, and will have a solid system in place for verifying product functionality.

4. Broaden Your Horizons

From start to finish, a contract electronics manufacturer can speed up your processes while improving the design and production of your devices. Because of this, your business will become more efficient and organized, freeing up the time for you and your team to "dream big" and develop new, more exciting and technologically advanced products to share with your customers. At long last, you will have the time, technology, and financial resources available to become the industry leader that you always wanted to be.

Stop holding yourself back, and start finding out how working with a contract electronics manufacturer can transform your business into something bigger and better than ever before.

Topics: contract electronics manufacturer, electronic contract manufacturer, manufacturing machinery

5 Ways You Could Benefit From Assembly Manufacturing

In today's economy, many businesses are the outsourcing assembly manufacturing to overseas companies as a means of saving money. But although this is initially less expensive, in the long run, it could cost you big time. Bootlegged products, shoddy craftsmanship, and failure to comply with safety regulations could lead to significant losses in revenue, a damaged reputation, and even fines or lawsuits. Because of this, it is wise to bring assembly manufacturing back home, and work with an American based electronic contract manufacturer that specializes in the design and production of complex electronics. Here are just five of the many reasons why doing this could work to your advantage.

1. Fast, Attractive Prototypes

When you are taking on a new client who is interested in the electronic products that you have to offer, they will want to see an example of your work before signing a contract and giving you their business. In some cases, your clients may need a device that is customized to their specific needs, which means that you will need to have the ability to quickly design and produce a workable prototype. A professional contract manufacturer will be able to help you to come up with a flawless design plan, and through a high-tech assembly manufacturing process, you can turn out the prototype fast. This will give your new client the assurance that you can work at high seed, while still creating a quality products and meeting their demands.

2. Catch Errors Quickly

An offshore company may utilize non-skilled labor as a cheap means of handling the assembly manufacturing process. Unfortunately, this means that hundreds of your products could be put together incorrectly, or with faulty parts before anyone notices. In fact, your device could actually end up on store shelves or shipped to your customers before the mistakes are detected. An experienced American contract manufacturer will be staffed with experts who will be able to prevent problems like these from happening. Skilled workers with a trained eye will be able to spot issues quickly and fix them to minimize losses and uphold your reputation.

3. Utilize the Best Technology

When you have an assembly manufacturing partner, there's absolutely no need for your business to continuously try to "keep up with the Joneses" in terms of investing in better, more advanced equipment. Your contract manufacturer will keep their facility current with the latest and greatest machinery for producing electronics, so that you can take advantage of advanced machinery and precision robotics without spending a dime of your own.

4. Testing and Quality Control

With the right contract manufacturer, you can count on the fact that your products will be manufactured correctly, from start to finish. Your partner will even test your completed devices in-house to ensure functionality and operability before sending them to your clients. This will ultimately prevent the losses and embarrassment involved with having to recall a product, or re-do an entire order as a result of overlooked flaws and mistakes.

5. Sell the Best Products

At the end of the day, your primary objective is to give your customers and clients the best possible electronics possible. If you are trying to handle large orders in-house, you may struggle to keep up with demand, which will lower the quality of your devices. On the other hand, we have already seen how outsourcing the assembly manufacturing process to an offshore location can be damaging to both your company and the end users.

Topics: assembly manufacturing, electronic contract manufacturer

Don't Throw It Away, Use Electronics Repair Services Instead

Although it's unfortunate, we live in a very wasteful society. If something stops working, very few people take the time to fix it - the item is simply discarded and replaced. In the world of electronics manufacturing, however, this isn't always a possibility. After spending a great deal of time in the engineering design services phase and spending the money to manufacture a prototype or product, simply "junking" a malfunctioning device could result in the loss of thousands or even tens of thousands of dollars - and that doesn't include the amount of money lost on the potential sales of the product, had it been successful.

Topics: electronics repair services, electronics contractor, repair electronics services

Bigger doesn't always mean better - especially in the world of technology. As the digital revolution continues to expand our capabilities, electronic devices continue to shrink into smaller, more compact units. Because of this, electronics companies must take advantage of advancements in manufacturing technologies like PCB assembling.

Topics: pcb assembly, PCB Assembling, pc board assembly

A Printed Circuit Board, abbreviated as PCB is a foundation used in the design of electrical gadgets. It plays to important roles:

Topics: pcb assembly, electronic assembly, electronic PCB assembly

EMS (Electronic Manufacturing Services) generally refers to companies that design, test, manufacture and sell electronic gadgets while offering a return/repair services or assembly of original electronic equipment. While this might sound as an easy task, it is a hard to achieve investment that once up and running will deliver quality assurance to a wide variety of customers and a go.

Topics: electronics manufacturing, ems electronics, electronic design