IPC's Validation Services Program has awarded an IPC 1791 Trusted Assembler and the IPC 610 QML (Qualified Manufacturers Listing) to Zentech Dallas, a wholly owned subsidiary of Zentech Manufacturing. Following an initial audit by IPC, Zentech Dallas joins Zentech Baltimore in the elite group of U.S. trusted sources and suppliers with these certifications.

Topics: contract manufacturing company, electronic PCB assembly, Electronics Manufacturing Services Industry, US manufactured products, Maryland PCB assembly, PCB manufacturing, electronics manufacturer

If you haven't heard, the electronics manufacturing market is shifting rapidly! In response to the cut-rates being offered in developing nations, domestic facilities are now adding services you simply cannot get overseas. These can be extremely cost-effective, and add significant value to local manufacturing choices.

Topics: assembly manufacturing, contract manufacturing company, PCB Repair Services

Large or Small: A Good Contract Manufacturing Company Can Handle It All

As a growing electronics company, new business is always welcome. You're constantly looking for ways to reach new customers and grow your client base. But what happens if a major client orders a large batch of boards that you simply don't have the time or means to fulfill before the required deadline? What if a small, new client with the potential for exciting growth in the future solicits your work, but you're unable to push current customer orders onto the back burner? Does this mean that you'll have to lose the opportunity to take on new business? We don't think so.

A strong partnership with a contract manufacturer can help you manage orders and clients of all sizes so that you never miss out. Whether your CM is handling all of the PCB design and assembly on your behalf, or is only assisting you with a portion of the work, there's really no job that's too big or small. In fact, you'd be surprised at how much a good CM can do to help you to keep your PCB batch orders organized and to keep your customers happy and coming back for more.

Topics: contract manufacturing company, pcb design, pcb services

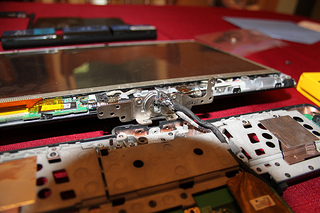

Surface Mounted Technology, What Is It All About?

What is Surface Mounted Technology (SMT)?

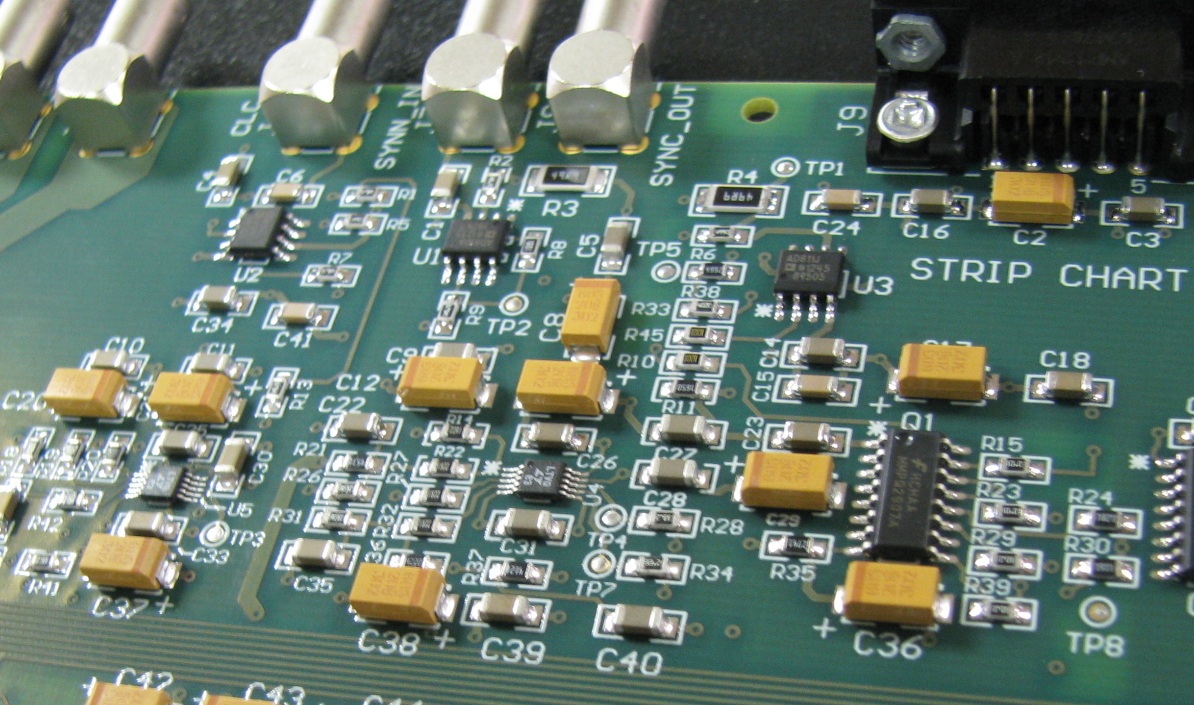

In SMT, components are placed directly onto the surface of a PCB in order to create what is known as a surface mount devise (SMD). Due to its efficiency and effectiveness, SMT has widely replaced through-hole technology methods for constructing PCBs, however, both methods can be utilized on the same PCB. This is because there are some components that are simply not suited to surface mounting. These components might include large transformers and heat-sinked power semiconductors. Generally speaking, SMT components are smaller in size than through-hole units as they have smaller leads or do not have any leads at all.

What are the Advantages of Surface Mounted Technology?

The primary advantage to SMT, of course, is size. Because today's electronics are expected to be more compact, there is an increase in demand for smaller units. SMT makes this possible. But despite the fact that these units are not as bulky as older devices, there is actually a much higher component density, as well as more connections per each component. This means that electronics can be more efficient and advanced than ever before, while still being as compact as possible. Fewer holes need to be drilled into the boards which leads to faster and more automated assembly processes, and the fact that components are able to be situated on either side of the circuit board simplifies things further. On top of this, there are many SMT parts and components that actually cost less than their through-hole counterparts. All of this results in a lower initial cost, less time required for setting up and production, reduced manufacture cost, and a more efficient use of time.

What are the Disadvantages of Surface Mounted Technology?

Unfortunately, there are no perfect or fool-proof manufacture processes, and SMT does have its drawbacks as well. As an example, SMT is not suited for any large, high-power/high-voltage parts. Because of this, SMT and through-hole construction may need to be combined for better results. Additionally, the small size of SMDs can create issues, in that the solder joint dimensions continue to grow smaller as advances are made toward ultra-fine pitch technology. Ultimately, this means that less solder is able to be used for each joint which can result in voiding, and integrity issues. The solder connections of SMDs are also capable of being damaged by plotting compounds as they go through thermal cycling. Lastly, SMT should not be used as the sole attachment method for any components that may be subject to ongoing mechanical stress, for instance, connectors that are utilized to interface with external devices which are often attached or detached.

When Should Surface Mounted Technology be Used?

Because of its many benefits, the majority of products manufactured at this time utilize surface mounted technology. Despite this, we have seen that SMT is not suitable in all cases. As a rule, SMT should be considered if:

- Your products must be very small/compact

- Your products must be able to accommodate large volumes of memory

- Your final product needs to be sleek and light despite component density

- Your product will need to be able to function at high speed/frequencies

- You need to produce large quantities with automated technology

- Your product should only transmit very little noise (if any at all)

- Your product must be able to accommodate a great deal of large, high lead-count complex ICs

Topics: contract manufacturing company, PCB Assembling, surface mounted technology

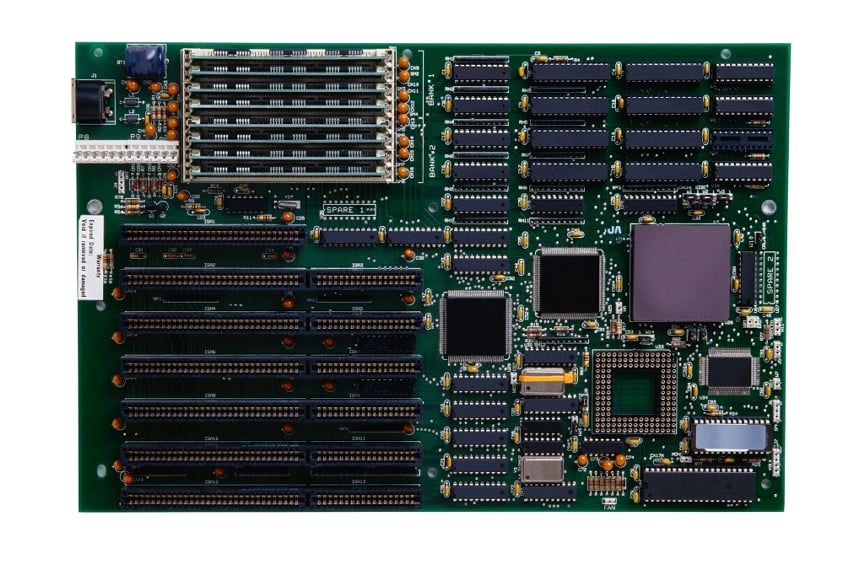

How Does Electronic Board Design Help You Create Your Product

Turn Your Ideas into Realities

Your products are only limited by your imagination - especially when you have the best designers and technologies on your side. Skilled engineers with decades of industry experience are more than capable of bringing your concepts and ideas to life through concise, efficient design schematics. Paired with state-of-the-art design software, you can rest assured that the plans for your electronic board design will be a cut above the rest and will give you a competitive edge. Even if you are in the works of developing a brand new device or prototype, you will be able to get your plans set into motion faster. And if you're stuck on a particular problem, your manufacturing partner will be able to pinpoint the issues and come up with a timely solution.

Leave Nothing to Chance

From start to finish, the right contract manufacturer will take care to ensure that your electronic board design is truly flawless. A lot of careful thinking and planning goes into developing the schematics for your product so that it operates seamlessly. Be sure to work with a partner who is able to offer a full range of design services that span throughout the entire product life cycle, such as:

- Product requirements review

- System design

- Circuit design

- Mechanical design

- Embedded Software (firmware)

- Algorithm development

- Testing strategies

- Documentation creation/management

- Sustaining engineering

- RoHS Compliance

There is no reason that working with a contract manufacturing company for electronic board design should not help your business to save both time and money. Your partner's engineers should work diligently to ensure that all of your internal technical resources are utilized exactly when and where you have planned, for maximum value and efficiency. Additionally, your partner should be mindful of keeping your project on schedule and on point with your budget. By taking advantage of automated software programs and skilled employees, your project can be completed faster than had you chosen to go it alone, and errors can be avoided. In the long run, this will save the costs and hassle associated with troubleshooting for faults and redesign. In addition to all of this, experienced contract manufacturers may be able to cut down on the amount of materials required for your project's design, reducing your production costs even further. Multiplied by hundreds of boards, this can make a significant difference in your budget.

Constantly Improve Your Business

When you have help with the electronic board design process, the minds of your internal designers and engineers are freed up to develop bigger and better ideas. This means that you can be constantly moving toward higher goals and expanding your business. With a greater offering of products and high-tech devices, you will expand your market base and effectively grow your business. As your ideas become more advanced and the demand for your products grows, you will not be held back by a lack of experience, manpower, or technology, as your partner will be able to keep you moving forward.

The success of your business all begins with the initial electronic board design process. By taking the time to get it just right, you can grow your company and thrive. How could you benefit from professional electronic board design services?

Topics: contract manufacturing company, electronic board design, egineering design services

Should Your Business Be Using A Contract Manufacturing Company?

Are you wondering whether or not your electronics business would benefit from a partnership with a contract manufacturing company? Although every company is different and has its own needs, there are certain factors that make it very obvious when an operation is in need of a little outside help. To help you make the best decision for your business, here are the top six signs that you should hire a contract electronics manufacturer.

1. You feel that your product design process could be streamlined

Time is money, so when it starts taking too long for your designers or project engineers to come up with a simple strategy for your electronics devices, it's time to ask for some help from a contract manufacturing company. This isn't to say that your current team is incapable of the task at hand, but rather, that they could benefit from a bit of outside perspective. After spending hours pouring over plans and schematics, your staff may simply be too burned out to notice that there could be a simpler, more efficient way of creating your products so as to save the entire business money. By working with engineers from a third party, your team will develop even more experience and may eventually only need help on a decreased consultation basis. Regardless, it's always good to have another set of eyes on each project.

2. You struggle to produce large product orders

Although your goal is to grow your business, you may be "stuck" if you don't have the manpower or machinery necessary to actually fulfill large purchase orders from major clients. In this case, you won't be able to meet your objectives until you have the assistance of a contract manufacturing company with the ability to turn out higher volumes of your electronic devices.

3. It is growing increasingly difficult for you to manufacture small, complex devices

As technology advances, it continues to become smaller, lighter, and more compact. Unfortunately, this means that minuscule and extremely complex components must be manipulated during the assembly process. If you're relying on human labor, or dated and clumsy machinery to put your devices together, you could be in trouble. In this case, it would be to your benefit to work with a third party manufacturer who could enable you to take advantage of advanced production technologies and robotics for assembly.

4. You're throwing away too much money on correcting design or production problems

There's nothing worse than spending the time and money on producing a batch of faulty electronics. This often happens when smaller companies feel too rushed to complete an order and lack the manpower to keep an eye on what's going on. Now you must go back and determine where in the design or manufacture process something went wrong and make the necessary corrections. When you've got a professional contract manufacturing partner on your side, however, you can rest assured that your products will be regularly and systematically tested for flaws so that they are detected and corrected early.

5. Your cost to purchase quality parts is too high

If you're spending too much money on parts, it's impossible for you to sell your products at a competitive price point. Purchasing cheap, bootlegged parts from overseas, however, creates even bigger problems for your reputation. So what's the answer? A seasoned contract manufacturing company will have established strong relationships with suppliers, meaning that you can enjoy quality parts for less of a cost.

6. You require assistance for troubleshooting and repairing equipment

When a customer sends a product back, are you able to quickly pinpoint the problem and fix it? If this is too time-consuming for your team, you should consider working with a third party company to speed up the process. Not only will this cut your costs, but it will keep your customers happier.

So what's the verdict? Should you be using a contract manufacturing company?

Topics: contract electronics manufacturer, contract manufacturing company, advanced production technologies

Electronics Contract Manufacturing: Simple Yet Complex

Because the majority of the population relies upon the use of electronics each day, it is becoming increasingly important for these devices to be user-friendly. Most people want to be able to utilize light, compact technology that will allow them to accomplish multiple tasks in a relatively simplistic manner. But even though the goal of manufacturers is to develop simplistic products for their end users, the design and production process still remains quite complex. As such, a growing number of companies are beginning to turn to electronics contract manufacturing services for help in developing high-quality tech that will please the masses. Here's a quick look at what goes into developing even the most simplistic units, and why a bit of outside help is often needed.

Four Complex Steps Involved in Creating Simple Electronics

1. Understand consumer needs

It's been said that you can't please everyone all the time, but when you're developing technology for a large group of end-users, you've got to give it your best shot. The first step to developing an electronic device that will be profitable for your business is to take the time to learn exactly what it is that your target audience wants and needs. Although this may sound like a simple enough task, you may find yourself quickly becoming overwhelmed by the many demands of your market. This is where the assistance of an electronics contract manufacturing company may come in handy. With superior electronics design and production experience, your business partner may be able to help you to find ways to condense and consolidate consumer desires, making your product less costly to create, and more desirable to your customers.

2. Design multi-functional devices that's easy to use

Once you've got a strong, working idea of what it is that your product will actually need to be able to do, you've got to find a way to make it simple for your customers to use. Although your team may have the intelligence and skills required to understand and design extremely complex technology, they may struggle with the ability to scale it back a bit and make it extremely easy for end-users to manipulate. If your engineers have hit any roadblocks, they may benefit from a new set of eyes. Your electronics contract manufacturing service can help to simplify the plans, resolve any issues, and make sure that your consumer market will be able to perform even the most complex operations with just a few clicks of a button.

3. Manufacture products that are tech-dense, but lightweight

Today's customers want electronics that are lightweight and small, so you must find a way to meet their demands. Unfortunately, working with tiny components and parts by hand can be very time-consuming, costly and difficult, and can result in human errors. At the same time, the cost to purchase robotic arms that could easily manipulate these components can be overwhelming for small to mid sized businesses. The good news is that a professional contract manufacturing partner will enable you to take advantage of robotics and other advanced technology to produce your devices faster and more precisely than ever before.

4. Test for functionality and user friendliness

Finally, you must always test your electronics before introducing them to the mass marketplace. In addition to performing an in-house check for functionality, it's also wise to gather a small test audience to determine how easy it actually will be for your consumers to learn how to operate your devices and perform tasks. Should there be any hiccups along the way, you'll need to go back and correct the issues so that your market will have the best possible response to your product. In order to solve these problems for the lowest cost and with the fastest turnaround time, it's wise to team up with your electronics contract manufacturing vendor.

Topics: contract manufacturing company, electronics design, electronics contract manufacturing

What To Expect From Top Notch Manufacturing Services

If you're shopping around for a contract manufacturing company, you're well aware of the fact that you have many options to choose from. Unfortunately, though, not all manufacturing services are equal. In order for your business to truly thrive, you must take the time to find a partner company that is passionate about providing quality services and products. Here's a closer look at what it is that you should expect from your manufacturing agency.

Open Communication and Collaboration

The best manufacturing services will always keep the lines of communication open between themselves and their clients. It should never be difficult for you to get in touch with your contract manufacturer to set up a a consultation, to review design schematics, to discuss any issues or deadlines, or to find out the status of the production of an order of electronics devices. On the other side of things, your manufacturing service should also contact you with regular updates, or to talk about any problems that have been encountered or changes that have been made to improve the design of your product. Regardless of whether you are leaving product design completely in the hands of your contract manufacturer, or if you're looking to collaborate with experts on ways to improve your schematics, no action should ever be taken without your approval.

Excellent Parts

Your electronics devices cannot function as they should unless the parts used to construct them are top notch. Unfortunately, this is the area where many manufacturing services fall short. Often, electronics companies look overseas to outsource the manufacture of their products because the services rendered are typically cheaper. But when making decisions like these, you must remember that you get what you pay for. Many offshore manufacturing services are able to lower their price points because they are cutting corners and utilizing bootlegged parts. This can create serious problems with the functionality of your devices and can sometimes even result in safety issues. Ultimately, your customers will be dissatisfied with their products, leaving you with the costly burden of replacing their devices or even going back to the drawing board as you are required to recall the product altogether. In the end, you will have lost money and your reputation will have been severely damaged.

Choosing to work with an American company with a solid reputation, on the other hand, will ensure that the parts used in the production of your devices will be of the highest quality possible, so that you can be proud of the products that you put on the shelves for your consumers.

Technologically Advanced Machinery

When choosing between electronics manufacturing services, take a look at the types of technology and machinery that they utilize during the production of complex devices. High-tech facilities will deliver the best products. Robotic arms, for example, are essential to manipulating very small parts in a way that is efficient and precise. Be sure that the product assembly process makes use of the latest and greatest equipment for quickly generating your product without detracting from accuracy and operability.

Quality Control

Professional manufacturing services will never allow your product to go to consumers without being carefully tested for functionality and safety. Be sure that your contract manufacturer has a proven process for checking over assembled devices to ensure that your customers will be fully satisfied with your electronics devices. In electronics manufacturing, there is no "good enough". In order for you to remain competitive and successful, your products must always be the best, and your manufacturer should understand this principle.

By insisting on these criteria, you'll find the best manufacturing services possible.

Topics: contract manufacturing company, manufacturing services, electronics manufacturing services